Understanding the Benefits of FR4 Glass Epoxy Sheet in Electronics

2025-03-12 17:40:49

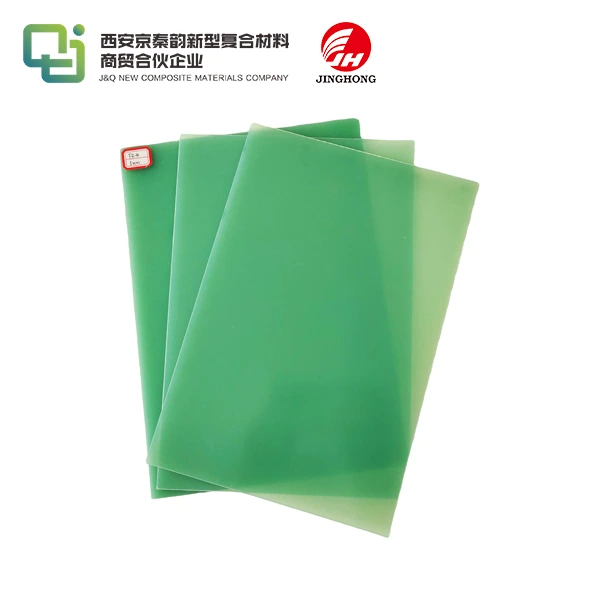

FR4 glass epoxy sheet has become an indispensable material in the electronics industry, revolutionizing the way we design and manufacture circuit boards. This versatile composite material combines the strength of woven fiberglass with the insulating properties of epoxy resin, resulting in a substrate that offers exceptional durability, electrical insulation, and thermal resistance. As electronics continue to evolve, becoming smaller, faster, and more complex, FR4 glass epoxy sheets have proven to be a reliable foundation for printed circuit boards (PCBs) across various applications. From consumer electronics to aerospace technology, the benefits of FR4 glass epoxy sheets have made them the go-to choice for engineers and manufacturers seeking high-performance, cost-effective solutions for their electronic designs.

Composition and Manufacturing of FR4 Glass Epoxy Sheets

Raw Materials and Their Properties

FR4 glass epoxy sheets are composed of a carefully engineered blend of materials. The primary components include woven fiberglass cloth and epoxy resin. The fiberglass provides structural integrity and dimensional stability, while the epoxy resin acts as a binding agent and electrical insulator. This combination results in a material with excellent mechanical strength, thermal resistance, and dielectric properties.

Production Process

The manufacturing of FR4 glass epoxy sheets involves a meticulous process. Initially, multiple layers of fiberglass cloth are impregnated with epoxy resin. These layers are then stacked and subjected to heat and pressure in a lamination process. This procedure ensures the thorough integration of the fiberglass and resin, creating a homogeneous material with consistent properties throughout its thickness.

Quality Control Measures

Rigorous quality control measures are implemented throughout the production of FR4 glass epoxy sheets. These include tests for physical properties such as tensile strength and flexural modulus, as well as electrical characteristics like dielectric constant and dissipation factor. Advanced techniques such as X-ray diffraction and thermal analysis are often employed to verify the material's composition and performance attributes.

Electrical and Thermal Properties of FR4 Glass Epoxy Sheets

Dielectric Strength and Insulation Resistance

FR4 glass epoxy sheets are highly valued for their remarkable dielectric strength, which enables them to endure substantial voltages without experiencing breakdown. This makes them especially useful in high-power electronic devices, where reliable insulation is crucial. Additionally, their excellent insulation resistance ensures minimal current leakage between conductive traces, thereby maintaining the integrity and performance of circuit boards. This combination of durability and electrical performance makes FR4 a preferred material for various advanced electronic applications.

Thermal Conductivity and Coefficient of Thermal Expansion

FR4 glass epoxy sheets have a relatively low thermal conductivity, which helps to reduce the transfer of heat within electronic devices. This feature is especially beneficial in applications where efficient thermal management is necessary to prevent overheating and maintain optimal performance. Furthermore, the material's coefficient of thermal expansion is precisely engineered to align with that of copper, minimizing the strain on solder joints and component connections during temperature changes. This ensures long-term reliability and stability of the device.

Flame Retardancy and Heat Resistance

The "FR" in FR4 stands for "flame retardant," emphasizing the material's important safety characteristic. FR4 glass epoxy sheets are designed to resist ignition and self-extinguish when exposed to flames, which significantly lowers the risk of fire in electronic applications. In addition to their flame-resistant properties, these sheets retain their structural strength and electrical performance even at high temperatures, making them ideal for use in demanding environments where reliability and safety are critical.

Applications and Advancements in FR4 Glass Epoxy Sheet Technology

Versatility in Electronic Design

FR4 glass epoxy sheets are widely used in a variety of electronic devices, ranging from basic single-layer PCBs to intricate multi-layer boards. This material serves as the backbone for a diverse array of electronic products, supporting both simple and highly advanced designs. Its versatility enables the development of high-density interconnects, which are essential for the miniaturization of electronic devices. By maintaining excellent performance and reliability, FR4 helps meet the increasing demand for compact, high-performance technology in modern electronics.

Emerging Trends in FR4 Formulations

As the electronics industry advances, FR4 technology has also evolved to meet modern environmental standards. New halogen-free FR4 variants have been developed to address concerns over the environmental impact of traditional flame retardants, which can release harmful substances when disposed of. These eco-friendly formulations retain the same high-performance characteristics as conventional FR4, including durability, electrical reliability, and flame resistance, while minimizing the environmental footprint. This makes them a more sustainable choice for manufacturers and consumers alike, supporting the industry's shift toward greener electronic solutions.

Integration with Advanced Manufacturing Techniques

The versatility of FR4 glass epoxy sheets has made them an ideal material for advanced manufacturing processes. Laser drilling technology enables the creation of ultra-fine vias in high-density interconnect (HDI) boards, which are essential for compact and complex designs. Furthermore, FR4's stability supports the use of sophisticated surface finishes and the integration of embedded passive components, enhancing both the functionality and reliability of electronic assemblies. This compatibility with cutting-edge techniques ensures that FR4 remains a vital component in the evolution of modern electronics.

Conclusion

FR4 glass epoxy sheets have proven to be a cornerstone in the realm of electronic manufacturing. Their unique combination of electrical, thermal, and mechanical properties makes them an ideal substrate for a vast array of applications. As technology continues to advance, the versatility and reliability of FR4 glass epoxy sheets ensure their continued relevance in the electronics industry. From consumer devices to critical aerospace systems, these materials provide the foundation for innovation and progress in electronic design and manufacturing.

Contact Us

For more information about our FR4 glass epoxy sheets and other insulating materials, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your electronic manufacturing needs.

References

1. Johnson, R. W., & Yamane, L. H. (2019). Advanced Materials for High-Performance PCBs. Journal of Electronic Materials, 48(10), 6215-6229.

2. Zhang, X., & Liu, Y. (2020). Thermal Management in Modern Electronics: A Review of Materials and Techniques. Applied Thermal Engineering, 168, 114838.

3. Chen, H., & Wang, Q. (2018). Flame Retardant Mechanisms in FR4 Laminates for Electronic Applications. Polymer Degradation and Stability, 152, 280-290.

4. Smith, A. B., & Brown, C. D. (2021). Environmental Impact of Halogen-Free FR4 Alternatives in PCB Manufacturing. Green Chemistry, 23(8), 2987-3001.

5. Tanaka, K., & Nakamura, T. (2017). High-Frequency Characteristics of FR4-Based Substrates for 5G Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 7(5), 787-793.

6. Lee, S. H., & Park, J. K. (2022). Recent Advances in FR4 Glass Epoxy Sheet Technology for Next-Generation Electronics. Advanced Materials Interfaces, 9(12), 2101742.