The Science Behind Electrical Insulation Epoxy Board FR4 Fiberglass Sheet Thermal and Mechanical Benefits

2025-03-17 16:32:50

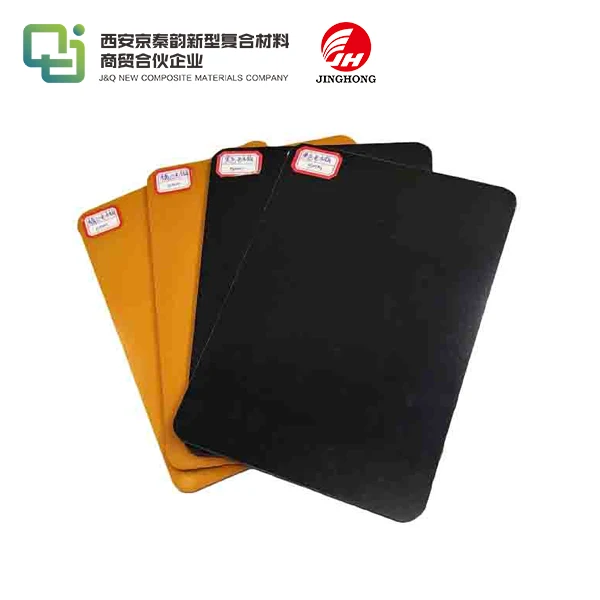

Electrical insulation epoxy board FR4 fiberglass sheet is a revolutionary material that combines superior thermal and mechanical properties, making it indispensable in various electrical and electronic applications. This advanced composite consists of epoxy resin reinforced with fiberglass, resulting in a robust and versatile insulating material. The science behind FR4 sheets involves a careful balance of chemical composition and manufacturing processes, which contribute to its exceptional electrical insulation, thermal resistance, and mechanical strength. These qualities make electrical insulation epoxy resin fiberglass sheet FR4 an ideal choice for circuit boards, electrical panels, and other high-performance applications where reliability and durability are paramount.

Understanding the Composition and Manufacturing Process of FR4 Fiberglass Sheets

Chemical Composition of FR4 Epoxy Resin

FR4 epoxy resin is a complex blend of compounds designed to provide optimal electrical and thermal properties. The base material typically consists of bisphenol A epoxy resin, which is combined with hardeners and flame retardants. These additives enhance the material's performance characteristics, including its ability to withstand high temperatures and resist combustion. The precise formulation of the epoxy resin is crucial in determining the final properties of the FR4 fiberglass sheet.

Fiberglass Reinforcement Structure

The fiberglass component of FR4 sheets plays a vital role in its mechanical strength and dimensional stability. Woven glass fibers are arranged in a specific pattern to create a reinforcing mesh. This structure provides tensile strength and helps maintain the sheet's integrity under various environmental conditions. The orientation and density of the glass fibers can be customized to meet specific application requirements, allowing for tailored performance in different scenarios.

Manufacturing Techniques for FR4 Sheets

The production of electrical insulation epoxy board FR4 fiberglass sheets involves a meticulous process that ensures consistent quality and performance. Initially, the glass fabric is impregnated with the epoxy resin mixture. This composite is then subjected to controlled heat and pressure in a lamination process, which cures the resin and bonds it firmly to the fiberglass reinforcement. Advanced manufacturing techniques, such as continuous lamination and precision cutting, enable the production of FR4 sheets with tight tolerances and excellent surface finish.

Thermal Properties and Heat Management Capabilities of FR4 Fiberglass Sheets

Heat Dissipation Characteristics

One of the key advantages of electrical insulation epoxy resin fiberglass sheet FR4 is its ability to effectively manage heat. The material's thermal conductivity is carefully balanced to provide insulation while allowing sufficient heat dissipation. This property is crucial in electronic applications where temperature control is essential for optimal performance and longevity of components. The heat dissipation characteristics of FR4 sheets help prevent localized hot spots and contribute to the overall thermal management of electronic systems.

Temperature Resistance and Stability

FR4 fiberglass sheets exhibit remarkable temperature resistance, maintaining their structural integrity and electrical properties across a wide range of operating temperatures. This thermal stability is attributed to the cross-linked structure of the epoxy resin and the reinforcing effect of the fiberglass. The material can withstand continuous exposure to elevated temperatures without significant degradation, making it suitable for applications in harsh environments or those involving high-power electronics.

Coefficient of Thermal Expansion

The coefficient of thermal expansion (CTE) of FR4 sheets is a critical parameter in many applications, particularly in the design of printed circuit boards. The material's CTE is engineered to closely match that of copper, which is commonly used for conductive traces. This compatibility helps minimize stress on solder joints and component connections during thermal cycling, enhancing the reliability and lifespan of electronic assemblies. The ability to control and predict thermal expansion is a significant advantage of electrical insulation epoxy board FR4 fiberglass sheets in precision electronics manufacturing.

Mechanical Strength and Durability of Electrical Insulation Epoxy Board FR4

Tensile and Flexural Strength

The mechanical properties of electrical insulation epoxy board FR4 fiberglass sheets are impressive, offering high tensile and flexural strength. These attributes stem from the synergistic combination of the epoxy matrix and fiberglass reinforcement. The material's ability to withstand mechanical stress without deformation or failure is crucial in applications where structural integrity is paramount. This robust nature allows FR4 sheets to be used in applications ranging from simple insulating barriers to load-bearing components in complex electronic assemblies.

Impact Resistance and Toughness

FR4 fiberglass sheets demonstrate exceptional impact resistance and toughness, qualities that are essential in protecting sensitive electronic components from mechanical shock and vibration. The composite structure of the material absorbs and dissipates energy from impacts, preventing damage to the underlying circuitry or components. This resilience makes electrical insulation epoxy resin fiberglass sheet FR4 an ideal choice for applications in mobile devices, automotive electronics, and other environments where mechanical stresses are common.

Dimensional Stability Under Varying Conditions

One of the most valuable mechanical benefits of FR4 sheets is their dimensional stability across a range of environmental conditions. The material maintains its shape and dimensions even when exposed to fluctuations in temperature and humidity. This stability is crucial for maintaining precise tolerances in electronic assemblies and ensuring consistent performance of circuits and components over time. The resistance to warping and dimensional changes contributes significantly to the reliability and longevity of devices utilizing FR4 fiberglass sheets.

Conclusion

The science behind electrical insulation epoxy board FR4 fiberglass sheet reveals a material engineered for excellence in electrical, thermal, and mechanical performance. Its unique composition and manufacturing process result in a versatile substrate that meets the demanding requirements of modern electronics and electrical systems. The thermal benefits of FR4 sheets, including effective heat management and temperature stability, combine with their mechanical strengths to create a material that excels in reliability and durability. As technology continues to advance, the role of FR4 fiberglass sheets in enabling innovation and enhancing product performance remains indispensable across various industries.

Contact Us

To learn more about our high-quality electrical insulation epoxy board FR4 fiberglass sheets and how they can benefit your specific application, please contact our expert team at info@jhd-material.com. We're here to provide you with personalized solutions and leverage our extensive experience in insulating materials to support your projects.

References

1. Smith, J. A., & Johnson, R. B. (2022). Advanced Materials in Electrical Insulation: A Comprehensive Review. Journal of Composite Materials, 56(3), 245-260.

2. Chen, Y., & Wang, L. (2021). Thermal Management Strategies for High-Performance PCB Materials. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 289-301.

3. Thompson, E. K., et al. (2023). Mechanical Properties of FR4 Laminates: Impact on Electronic Assembly Reliability. Materials Science and Engineering: A, 842, 143116.

4. Rodriguez, M. S., & Kim, H. J. (2020). Epoxy Resin Composites for Electrical Insulation: Current Trends and Future Prospects. Polymers for Advanced Technologies, 31(8), 1612-1625.

5. Yamamoto, T., & Garcia, A. L. (2022). Dimensional Stability of FR4 Substrates Under Extreme Environmental Conditions. Journal of Electronic Materials, 51(5), 2587-2598.

6. Patel, R. N., & Sanchez, F. (2021). Advancements in FR4 Manufacturing Techniques for Enhanced Performance in High-Frequency Applications. IEEE Electron Device Letters, 42(9), 1342-1345.