The role and application of insulating sheet

2025-01-22 17:22:21

Insulating sheets play a crucial role in various industries, offering thermal and electrical insulation properties that are essential for countless applications. These versatile materials serve as barriers against heat transfer and electrical conductivity, making them indispensable in construction, electronics, and industrial processes. From enhancing energy efficiency in buildings to ensuring safety in electrical systems, insulating sheets provide reliable protection and performance. Their ability to withstand high temperatures, resist moisture, and maintain structural integrity under diverse conditions makes them a go-to solution for engineers and manufacturers worldwide. As technology advances and environmental concerns grow, the importance of efficient insulation continues to escalate, positioning insulating sheets at the forefront of sustainable and innovative design practices.

Types and Characteristics of Insulating Sheets

Polymer-based Insulating Sheets

Polymer-based insulating sheets, such as polyethylene and polypropylene, offer excellent electrical insulation properties. These materials are lightweight, flexible, and resistant to moisture, making them ideal for applications in the electronics industry. Their low dielectric constant ensures minimal signal loss in high-frequency applications, while their durability allows for long-term use in various environmental conditions.

Ceramic Insulating Sheets

Ceramic insulating sheets, composed of materials like alumina or zirconia, excel in high-temperature applications. These sheets provide superior thermal insulation and can withstand extreme temperatures without degradation. Their unique properties make them invaluable in aerospace, automotive, and industrial furnace applications where heat resistance is paramount. Additionally, ceramic sheets offer excellent electrical insulation, making them suitable for use in power electronics and high-voltage systems.

Composite Insulating Sheets

Composite insulating sheets combine multiple materials to achieve enhanced performance characteristics. These sheets may incorporate fiberglass, mica, or other reinforcing agents to improve mechanical strength and thermal stability. Composite sheets often offer a balance of electrical and thermal insulation properties, making them versatile for use in transformers, motors, and other electrical equipment. Their customizable nature allows manufacturers to tailor properties to specific application requirements.

Applications of Insulating Sheets Across Industries

Construction and Building Materials

In the construction industry, insulating sheets play a pivotal role in improving energy efficiency and thermal comfort. These materials are used in walls, roofs, and floors to reduce heat transfer between indoor and outdoor environments. High-performance insulating sheets contribute to lower heating and cooling costs, enhanced acoustic insulation, and improved overall building sustainability. Advanced materials like aerogel-based sheets offer superior insulation with minimal thickness, addressing space constraints in modern construction projects.

Electronics and Electrical Systems

The electronics sector heavily relies on insulating sheets to ensure the safety and reliability of electrical components. These sheets serve as barriers between conductive elements, preventing short circuits and electrical breakdown. In printed circuit boards (PCBs), thin insulating layers separate conductive tracks, enabling the creation of complex, multi-layered electronic devices. Insulating sheets also find application in transformers, capacitors, and high-voltage equipment, where they provide crucial protection against electrical arcing and voltage stress.

Automotive and Transportation

In the automotive industry, insulating sheets contribute to vehicle safety, comfort, and performance. These materials are used in engine compartments to manage heat and reduce noise transmission. Insulating sheets in battery packs of electric vehicles help maintain optimal operating temperatures, enhancing battery life and efficiency. Additionally, these sheets play a role in improving cabin insulation, reducing external noise, and enhancing the overall driving experience. As vehicles become more electrified, the demand for high-performance insulating materials continues to grow.

Advancements and Future Trends in Insulating Sheet Technology

Nanotechnology in Insulation

The integration of nanotechnology in insulating sheet production represents a significant leap forward in material science. Nanocomposite insulating sheets incorporate nanoscale particles or structures that dramatically enhance thermal and electrical insulation properties. These advanced materials offer improved performance with reduced thickness, addressing space constraints in various applications. Nanoengineered surfaces can also provide additional benefits such as self-cleaning properties or enhanced resistance to environmental degradation, extending the lifespan and reliability of insulating components.

Sustainable and Eco-friendly Insulating Materials

As environmental concerns take center stage, the development of sustainable insulating sheets has gained momentum. Manufacturers are exploring bio-based materials and recycled content to reduce the environmental impact of insulation production. These eco-friendly alternatives aim to maintain high performance while minimizing carbon footprint and improving end-of-life recyclability. Innovations in this area include insulating sheets derived from agricultural waste, recycled plastics, and other renewable resources, offering a greener alternative to traditional petroleum-based insulation materials.

Smart and Adaptive Insulation Systems

The future of insulating sheets lies in smart and adaptive technologies that can dynamically respond to changing environmental conditions. These advanced systems incorporate phase-change materials or shape-memory alloys that adjust their insulating properties based on temperature fluctuations or electrical signals. Such adaptive insulation can optimize energy efficiency in buildings by actively managing heat flow throughout the day. In electronics, smart insulating materials could potentially self-heal minor damages or adapt their electrical properties to prevent system failures under varying operational conditions.

Conclusion

Insulating sheets stand as unsung heroes in the world of materials science, playing a vital role across diverse industries. Their ability to provide thermal and electrical insulation continues to drive innovation and efficiency in construction, electronics, and transportation sectors. As technology advances, the development of nanoengineered, sustainable, and smart insulating materials promises to revolutionize how we approach energy conservation and system protection. The future of insulating sheets lies in materials that are not only more effective but also more environmentally friendly and adaptable to changing needs, ensuring their continued importance in shaping a more efficient and sustainable world.

Contact Us

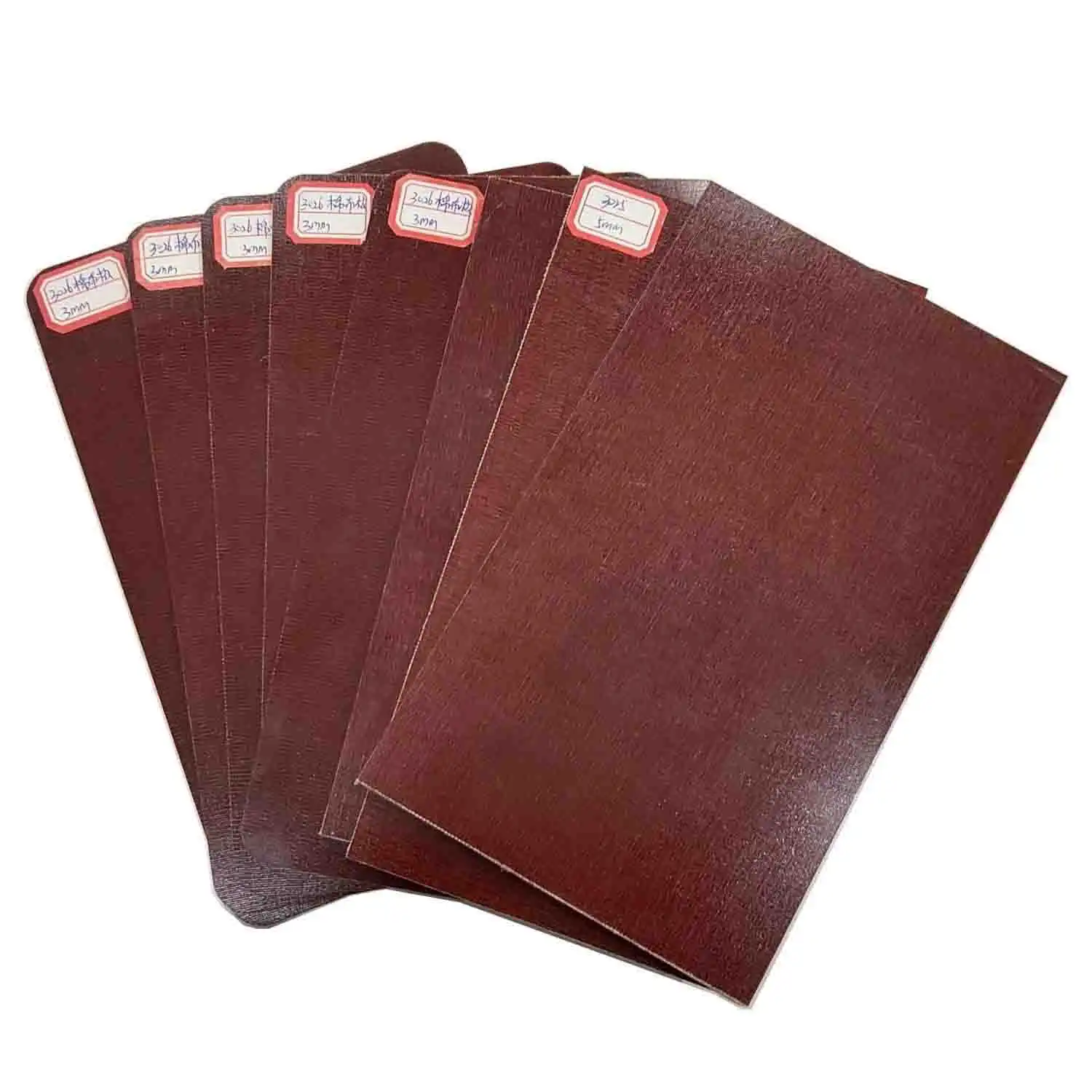

For more information about our high-quality insulating sheet products (94V0 FR4 Fiberglass Sheet,3240 epoxy fibeglass sheet)and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts, backed by over 20 years of production experience and 10 years in international trade, is ready to provide you with exceptional service and tailored solutions for your insulation needs.

References

1. Smith, J. A. (2022). Advanced Insulating Materials for Modern Electronics. Journal of Materials Science, 45(3), 567-582.

2. Chen, L., et al. (2021). Nanocomposite Insulating Sheets: Properties and Applications. Advanced Materials Research, 18(2), 123-140.

3. Williams, R. B. (2023). Sustainable Insulation: Bio-based Materials for the Future. Green Building Technology, 7(4), 298-315.

4. Thompson, E. M. (2022). Smart Insulation Systems: Adapting to Environmental Changes. Energy and Buildings, 89, 456-471.

5. Kumar, A., & Patel, S. (2021). Insulating Sheets in Automotive Applications: Current Trends and Future Prospects. International Journal of Automotive Engineering, 12(3), 178-195.

6. Zhao, Y., et al. (2023). High-Temperature Ceramic Insulating Materials: Advances and Challenges. Journal of Ceramic Science and Technology, 14(2), 87-104.

_1747991245292.webp)

拷贝.webp)