Research the application of polyethylene in sports equipment

2022-10-27

Polyethylene is a thermoplastic resin with excellent low temperature resistance, electrical insulation and resistance to most acid and alkali corrosion, which is widely used in production and life. Polyethylene products of different forms are widely used in the field of sports equipment. Among them, polyethylene fiber can be used to make racket netting and artificial lawn court; Polyethylene foam can be used to manufacture gymnastics mat; HDPE board can be used to manufacture buoy and ice board. In this paper, the application of polyethylene in the field of sports equipment is reviewed.

1. Polyethylene foam

In the field of sports, polyethylene foam is widely used in various protective facilities and floor mats. East China University of Science and Technology has developed a kind of chemical cross-linked polyethylene foam material with high resilience. This material has good resilience, high cell closure rate, and long service life. It is widely used in sports, protection, packaging, transportation and other fields. The preparation method is as follows: firstly, 80.0 phr low-density polyethylene and 20.0 phr ethylene propylene diene monomer rubber are put into an internal mixer for internal mixing. After the resin is melted and mixed, 10.0 phr azo dimethylphthalamide and 2.0 phr zinc oxide as foaming agent are added into the internal mixer for internal mixing for 3 minutes; Then, add 0.5 phr crosslinking agent diisopropylbenzene peroxide and cross-linking aid trimethylolpropane trimethyl acrylate into the internal mixer for internal mixing for 2 min, and take them out for open refining. The temperature of internal mixing and open mixing shall be controlled at 100~130 ℃. The blends obtained from the open mill are crushed and then added to the twin-screw extruder for granulation. The temperature is 100~125 ℃, and the screw speed is 30 r/min. The granules are added into a single screw extruder to extrude the sheet with a thickness of 2 mm and a width of 400 mm, the temperature is 100~125 ℃, and the screw speed is 30 r/min. The sheets are crosslinked and foamed in a three-stage heating foaming furnace. The furnace temperatures of 1~3 sections are 140 ℃, 160 ℃ and 190 ℃ respectively, and the mesh belt transmission speed is 1.5 m/min. The foamed material is cooled, shaped and rolled by the cooling roller and the traction roller to obtain a finished product with a width of 820 mm, a thickness of 5 mm and a density of 0.08 g/cm3. The rebound rate of finished products is 55%, which can be widely used in packaging, sports and protection, transportation and other fields.

Plastic floor mats used in gymnastics include polyethylene and PVC. PVC cushion is generally made of soft PVC. It is soft and tough, but feels soft. After using it for a period of time, whitening phenomenon will appear at the fold. Athletes often have a strong impact on the ground during practice, and the surface of such floor mats is prone to creases. Polyethylene floor mats are waxy and soft and wear-resistant to the touch, but these materials generally foam loosely. Athletes' sweat will penetrate into the floor mats during use, and they will not dry after being brushed. Jiangyin Civilized Sports Plastic Co., Ltd. has improved the gymnastics floor mat. The improved gymnastics floor mat consists of a surface layer and a core layer: the surface layer is an ethylene vinyl acetate copolymer with a thickness of 0.5~3.0 mm, the first core layer is a PVC layer with a thickness of 10~30 mm, and the second core layer is a highly foamed polyethylene with a thickness of 5~20 mm. The surface layer is closely connected with the core layer. The composite multilayer gymnastics pad can play a good cushioning role. After a long time of use, the surface is not easy to appear creases and water seepage, can be wiped with water, and has a long service life, which is suitable for gymnasts' training.

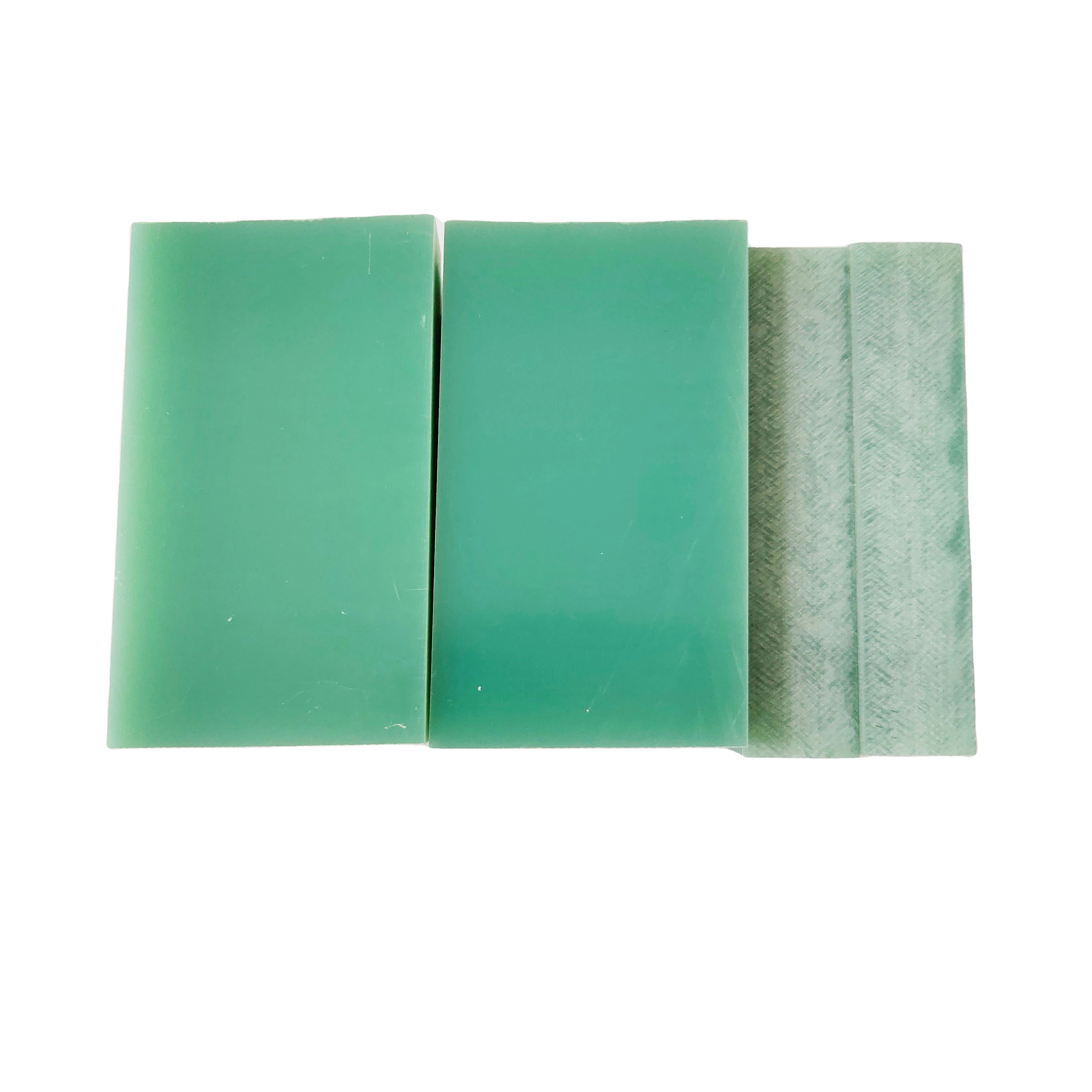

2. Polyethylene sheet

Polyethylene plastic sheet, especially ultra-high relative molecular weight polyethylene sheet, can be used to make skating ground, apron of skating rink, ground of roller skating rink, slide of amusement park, slide, sled skateboard, and is also widely used in the navigation field. Shanxi Zhongke Tiancheng Science and Technology Development Co., Ltd. manufactures ultra-high molecular weight polyethylene sheet by molding by adding 0.3% of polymer wax and 0.2% of stearic acid flow improver into high molecular weight polyethylene. The operating conditions of the molding sintering process: the hot pressing pressure is 51MPa, the temperature is 200 ℃, and the time is 90 minutes; The cold pressure is 22 MPa, the temperature is 65 ℃, and the time is 210 min. Shandong Baoerpu Industry Co., Ltd. has prepared an ultra-high relative molecular weight polyethylene sheet with high weather resistance, which consists of 0.3% color masterbatch, 1010.6% antioxidant, Tinuvin 327/328 0.5% ultraviolet light absorber, Chimassorb2020 0.5% hindered amine light stabilizer, and the base material is ultra-high relative molecular weight polyethylene powder with viscosity average molecular weight greater than 150 x 10 ^ 4. The preparation method is as follows: add the material into the mixer and stir it for 20 min, then lay it flat in the mold cavity of the molding machine, raise the temperature to 260 ℃, maintain the pressure at 6 MPa, and continue for 4 hours until the material is completely melted. Cool the mold cavity and raise the pressure to 7 MPa to form ultra-high molecular weight polyethylene sheet. The ultra-high molecular weight polyethylene sheet with high weather resistance can be obtained by pressure relief and demoulding. This kind of plate can be decolorized by Qiaoa, and is suitable for manufacturing sea aids, buoys for water sports, etc. However, the ultrahigh molecular weight polyethylene sheet prepared by common methods began to decolorize after 3 years.

The simulated skateboard can be laid in the stadium or in the open air, which has the advantages of low cost, removable disassembly and availability in all seasons. Beijing Zhong'ao Jinmiao Cultural Goods Co., Ltd. uses polyethylene, polydimethylsiloxane and nano antioxidant N, N '- II (β Polyethylene ice board was prepared from mononaphthyl) p-phenylenediamine, nano quartz sand, propylene glycol methyl ether acetate and pigments. Henan Jinhang Engineering Plastics Co., Ltd. has prepared ultra-high relative molecular weight polyethylene (UHMWPE) ice simulation plates using ultra-high molecular weight polyethylene, coupling agent, lubricant, glass beads or talc powder, fluorescent whitening agent, ultraviolet light absorber, antioxidant B215, lubricant microspheres, mineral oil microspheres, and nucleating agent. Rizhao Junqian Outdoor Products Co., Ltd. uses bolts to fix and connect the plates. By increasing or reducing the number of plates, the size of the site can be controlled. It can be used as both a skating rink and a swimming pool. It is easy to disassemble and move. Shandong Baoerpu Industrial Co., Ltd. has also developed a method for seamless welding of ultra-high molecular weight polyethylene sheets. Firstly, the butt joint shall be processed, and the edges of the two ultra-high molecular weight polyethylene sheets to be butt jointed shall be beveled respectively with a gradient of 40 °; Butt the two grooves on the hot press welding equipment, and fill the grooves with ultra-high molecular weight polyethylene sheet powder containing 1.6% of the mass fraction of additives and 0.3% of the mass fraction of the color masterbatch, which is 10 mm higher than the plate surface; The seamless welding equipment is used for heating and pressurizing. The temperature and pressure are basically the same as those in the process of preparing ultra-high molecular weight polyethylene sheet and last for 60 min. Finally, it is naturally cooled and pressurized to 12 MPa. After 120 min, it is depressurized and withdrawn. The appearance and physical properties of the plates at the butt joint shall be consistent with the ultra-high molecular weight polyethylene plates.

3. Conclusion

Polyethylene products in different forms are widely used in the sports field, which can improve the durability, impact resistance, heat resistance, vibration absorption performance of sports equipment. It can not only make athletes feel good about sports, but also protect athletes, prolong the service life of sports equipment and reduce production costs.