Is phenolic considered plastic?

2024-12-06 16:45:53

When discussing materials used in insulation and manufacturing, a common question that arises is whether phenolic is considered plastic. This query is particularly relevant for those in industries requiring high-performance materials with specific properties. Let's delve into the world of phenolic materials and explore their relationship with plastics.

Understanding Phenolic Materials

The Chemical Composition of Phenolic

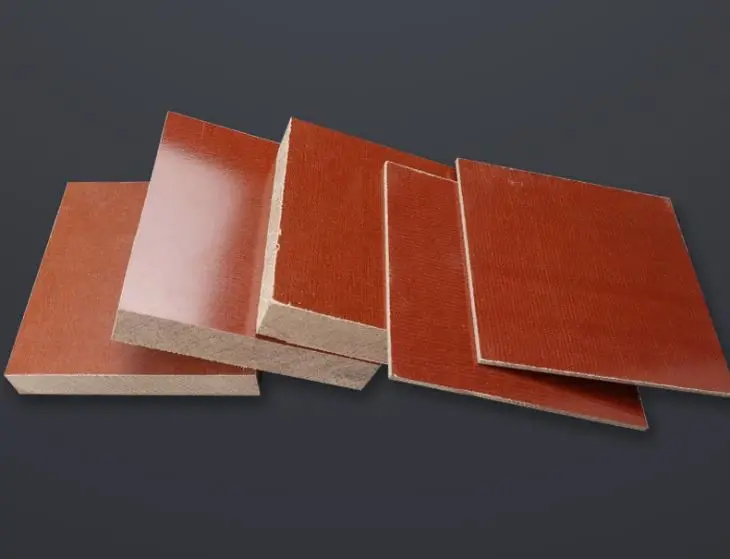

Phenolic materials, or phenol-formaldehyde resins, are a type of synthetic polymer formed by the reaction of phenol with formaldehyde under controlled conditions. This chemical process produces a durable thermoset resin with excellent heat resistance, electrical insulation, and chemical stability. These properties make phenolic materials ideal for applications in automotive, electrical, and construction industries.

Historical Development of Phenolic Resins

The origin of phenolic resins traces back to the early 1900s when Belgian-American chemist Leo Baekeland invented Bakelite, the first fully synthetic plastic. Baekeland’s revolutionary creation marked a milestone in material science, introducing a versatile and durable resin that could be molded into various shapes. This breakthrough laid the foundation for the mass production of phenolic materials, leading to their widespread adoption across multiple industries such as automotive, electrical, and consumer goods.

Characteristics of Phenolic Materials

Phenolic materials are known for their exceptional properties, such as superior heat resistance, excellent electrical insulation, and outstanding dimensional stability. These qualities make them highly valuable in demanding applications like electrical components, automotive parts, aerospace equipment, and even household items. The ability to withstand high temperatures and harsh environments, while maintaining structural integrity, makes phenolic resins indispensable in a variety of industries, offering both reliability and durability.

Comparing Phenolic to Traditional Plastics

Molecular Structure Differences

Although phenolic materials and traditional plastics are both polymers, their molecular structures vary greatly. Phenolic resins undergo a curing process that results in a rigid, three-dimensional network, making them strong and heat-resistant. In contrast, conventional plastics typically have linear or branched molecular chains, which offer flexibility but less structural stability under extreme conditions, limiting their performance in demanding applications.

Thermoplastics vs. Thermosets

A key difference between phenolic resins and traditional plastics is their response to heat. Traditional plastics are thermoplastic, meaning they can be heated, melted, and reshaped multiple times without altering their molecular structure. In contrast, phenolic resins are thermoset materials, which undergo a permanent chemical change during the curing process. This transformation creates a rigid, fixed shape that cannot be remelted or reshaped, making phenolic resins ideal for high-heat applications requiring durability and stability.

Performance in Extreme Conditions

Phenolic materials excel under extreme conditions, offering superior performance compared to many traditional plastics. Their remarkable heat resistance, flame retardancy, and chemical resistance make them particularly well-suited for high-stress environments such as automotive, electrical, and aerospace applications. In situations where conventional plastics would degrade or fail, phenolic resins maintain their integrity, ensuring long-term durability and reliability.

Applications and Advantages of Phenolic Materials

Industrial Uses of Phenolic Resins

Phenolic materials are widely utilized across diverse industries due to their unique properties. In the electrical sector, they are crucial as reliable insulators in circuit boards, switches, and connectors, helping to ensure safe and efficient operation. The automotive industry depends on phenolic composites for manufacturing heat-resistant parts, such as brake linings and engine components, while the aerospace sector uses phenolic resins for lightweight, durable materials in aircraft interiors, including insulation and structural components. These applications demonstrate the versatility and performance of phenolic materials in demanding environments.

Benefits in Insulation Applications

Phenolic materials excel in insulation applications due to their low thermal conductivity, making them highly effective in reducing heat transfer. Their inherent fire-resistant properties further enhance their appeal, ensuring safety in building insulation. Additionally, phenolic materials resist moisture absorption, preventing degradation over time and maintaining long-term durability. This combination of features makes them a reliable choice for a wide range of insulation needs, especially in challenging environments with fluctuating temperatures and humidity.

Environmental Considerations

While phenolic materials provide many benefits, their environmental impact warrants attention. Unlike thermoplastics, phenolic resins are not easily recyclable due to their thermoset structure, which undergoes irreversible curing. This makes disposal and recycling more challenging. However, ongoing research and innovation in material science are focused on developing more sustainable production methods, including bio-based alternatives and improved recycling processes, to reduce the environmental footprint of phenolic resins and enhance their lifecycle sustainability.

Conclusion

In addressing the question "Is phenolic considered plastic?", we find that the answer is not straightforward. While phenolic materials share some similarities with traditional plastics, their unique chemical structure, thermoset properties, and superior performance characteristics set them apart. Phenolic resins occupy a distinct category within the broader spectrum of synthetic polymers, offering unparalleled benefits in specific applications where conventional plastics fall short.

For industries requiring high-performance materials, particularly in insulation and manufacturing, understanding the nuances of phenolic materials is crucial. Their exceptional properties make them an invaluable resource in countless applications, from everyday consumer goods to cutting-edge technological innovations.

Contact Us

Are you looking for high-quality insulating sheets or seeking more information about phenolic materials? Our team at J&Q boasts over two decades of experience in producing and selling insulating sheets. We're here to provide expert guidance and top-notch products tailored to your specific needs. Don't hesitate to reach out to us at info@jhd-material.com for personalized assistance and to explore how our phenolic solutions can benefit your projects.

References

1. Baekeland, L.H. (1909). "The Synthesis, Constitution, and Uses of Bakelite." Journal of Industrial & Engineering Chemistry.

2. Gardziella, A., Pilato, L.A., & Knop, A. (2000). Phenolic Resins: Chemistry, Applications, Standardization, Safety and Ecology. Springer-Verlag Berlin Heidelberg.

3. Phenolic Resins: A Century of Progress. (2010). Springer New York.

4. Ibeh, C.C. (1998). Phenol-Formaldehyde Resins. In Handbook of Thermoset Plastics (Second Edition).

5. Knop, A., & Pilato, L.A. (1985). Phenolic Resins: Chemistry, Applications and Performance. Springer-Verlag Berlin Heidelberg.

6. Bakelite: The World's First Synthetic Plastic. (2007). American Chemical Society National Historic Chemical Landmarks.