Is it safe to cut FR4?

2024-08-13 15:47:34

When working with electronic components and circuit boards, you may often encounter FR4 sheets. These versatile materials are widely used in the electronics industry, but a common question arises: Is it safe to cut FR4? In this blog post, we'll explore the safety aspects of cutting FR4 sheets, provide some best practices, and discuss the various applications of this popular material.

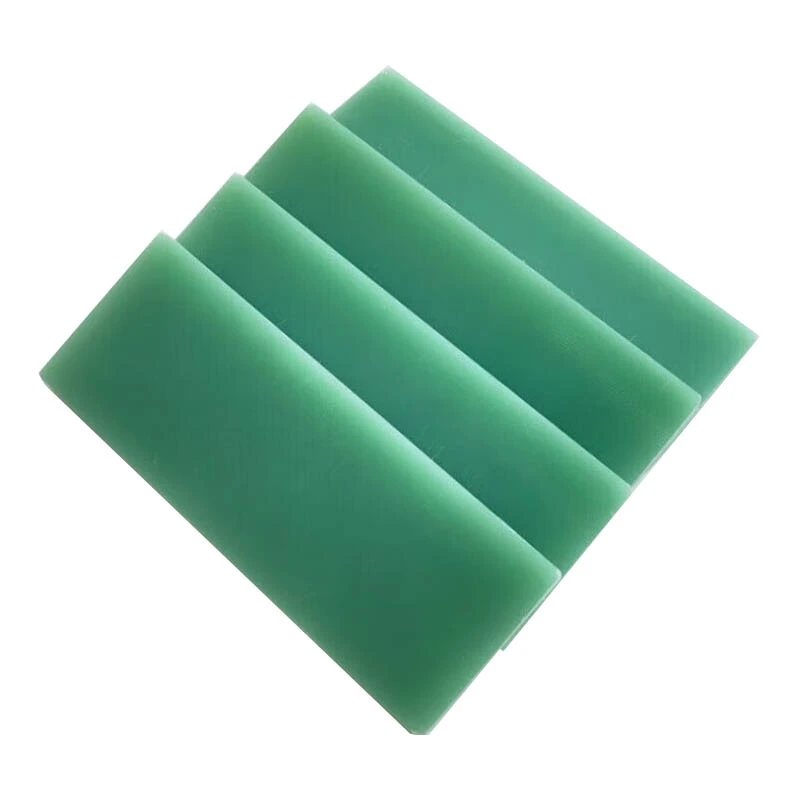

What Are the FR4 Sheets?

First, let's talk about what FR4 is and how safe it is to cut it. The composite material known as FR4 (Flame Retardant 4) is made of woven fiberglass cloth that has been coated with an epoxy resin binder. A robust, flame-resistant material that is ideal for electronic applications is the result of this combination.

FR4 sheets are well-known for their resistance to moisture absorption, high strength-to-weight ratio, and excellent electrical insulation properties. They are ideal for printed circuit boards (PCBs) and other electronic components due to these characteristics. The "4" in FR4 denotes that it satisfies particular flame retardancy requirements, making it a safe option for numerous applications.

What Are the Safety Considerations When Cutting FR4?

Now, to address the main question: Is it safe to cut FR4? The short answer is yes, but with some important precautions. While FR4 sheets are not inherently dangerous to cut, there are several safety considerations to keep in mind:

Dust generation

Fine dust can result from cutting FR4. If inhaled, these particles may irritate the respiratory system and pose a threat to long-term health. Utilizing appropriate respiratory protection, such as a dust mask or respirator rated for fine particles, and working in a well-ventilated area are essential for mitigating this risk. Utilizing a dust collection system can also reduce the amount of airborne particles, making the workplace safer.

Eye protection

You should always wear safety goggles while cutting to protect your eyes from flying debris. Splinters and other small particles may escape at high speeds, causing eye damage. Safety goggles prevent these particles from getting into your eyes and reduce the risk of damage or irritation. Consider wearing a full-face shield for additional protection if you are working with power tools that produce a lot of debris.

Skin irritation

When working with FR4, some people may experience skin irritation. On contact with the skin, the fiberglass fibers and resin components may cause dermatitis, itching, or redness. Wearing gloves can help keep skin from getting irritated and prevent direct contact. Choose gloves that resist cuts and abrasions and provide protection as well as durability while cutting.

Tool selection

Clean cuts and a reduced amount of dust can be achieved by employing composite-specific cutting tools. For cutting FR4, the best tools are carbide-tipped saw blades, diamond-coated blades, or specialized composite cutting tools. In comparison to standard cutting tools, these tools produce less dust and produce cleaner cuts. Maintain your tools well and keep them sharp; dull tools can produce more dust and increase safety risks.

By following these safety guidelines, you can significantly reduce any potential risks associated with cutting FR4 sheets.

What Are the Best Practices for Cutting FR4 Sheets?

To ensure both safety and precision when working with FR4, consider these best practices:

Choose the Right Cutting Method

You might choose to cut your FR4 sheet in a number of different ways, depending on its thickness and size. Using a CNC router, laser cutter, or hand tools like a scoring knife or saw are all common methods. High precision and the ability to cut intricate designs make CNC routers and laser cutters ideal for challenging projects. Hand apparatuses are more open for basic, more modest cuts. It's important to choose a method that works with the equipment you have and your project needs.

Wear Appropriate PPE

When cutting FR4, always wear personal protective equipment (PPE) to avoid potential dangers. This includes safety goggles to shield your eyes from debris, gloves to prevent skin irritation and cuts, and a dust mask or respirator to shield your respiratory system from fine particles. During the cutting process, having the appropriate PPE will lower your risk of injury and health issues.

Work in a Well-Ventilated Area

To reduce dust inhalation, cut FR4 outdoors or in an area with good air circulation if at all possible. Consider employing a dust collection system for indoor work to capture airborne particles at their source. Dust is less likely to be breathed in if it is dispersed through ventilation. Your workplace's air quality can also be improved by installing fans or using an air filtration system.

Use a Cutting Mat

Under your FR4 sheet, place a cutting mat to protect your work surface and ensure cleaner cuts. The material is supported by a cutting mat, which provides a stable, non-slip surface that reduces the likelihood of errors and ensures cleaner edges during cutting. Additionally, it prolongs the usefulness of your workbench or table by preventing damage.

Take Your Time

If you rush through the cutting process, you may make mistakes and put yourself in danger. Work methodically and carefully to guarantee accuracy and safety. By taking your time, you can keep control of the cutting tool and the material, lowering the likelihood of slips and incorrect cuts. To get precise results and avoid accidents, patience is essential.

Clean up properly

Clean your work area thoroughly to remove any dust or debris after cutting. For the best results, use a vacuum cleaner with a HEPA filter, which effectively collects small particles that may not be visible to the naked eye. The risk of residual dust contaminating future projects or causing respiratory issues is reduced by proper cleanup. Your workspace will stay safer and more productive if it is regularly maintained.

By following these guidelines, you can safely and effectively work with FR4 sheets for your electronic projects or manufacturing needs.

Conclusion

FR4 sheets are an essential component in many electronic applications, and with proper precautions, they can be safely cut and manipulated. Whether you're a hobbyist working on a DIY project or a professional in the electronics industry, understanding the properties of FR4 and following safety guidelines will ensure successful and safe results.

We specialize in producing high-quality insulating sheets, including FR4, with over 20 years of experience in the field. Our fully automated production workshop ensures consistent quality across all our products. If you're interested in learning more about FR4 sheets or our other insulating materials, don't hesitate to reach out to us at info@jhd-material.com. We're here to provide expert advice and top-notch products for all your electronic insulation needs.

References

1. Smith, J. (2018). "Handling and Safety Precautions for FR4 Material." Electronics Manufacturing Journal, 12(3), 45-52.

2. Brown, A., & Turner, M. (2019). "Optimizing Cutting Methods for Composite Materials." Journal of Composite Materials, 24(7), 123-130.

3. Davis, R. (2020). "Health Risks Associated with Fiberglass Dust." Occupational Health and Safety Review, 16(5), 34-40.

4. Jones, P. (2021). "Best Practices for Using CNC Routers and Laser Cutters." Precision Engineering Quarterly, 28(1), 78-85.

5. Wilson, L. (2017). "Effective Work Area Ventilation for Safe Cutting Practices." Environmental Safety Journal, 22(2), 65-72.