Is FR4 flammable?

2024-08-14 16:55:15

When it comes to electrical and electronic applications, safety is paramount. One material that often comes up in discussions about safety and performance is FR4 sheet. But a common question that arises is: Is FR4 flammable? This blog will dive into this topic and explore the properties of FR4, its flame-resistant characteristics, and its applications in various industries.

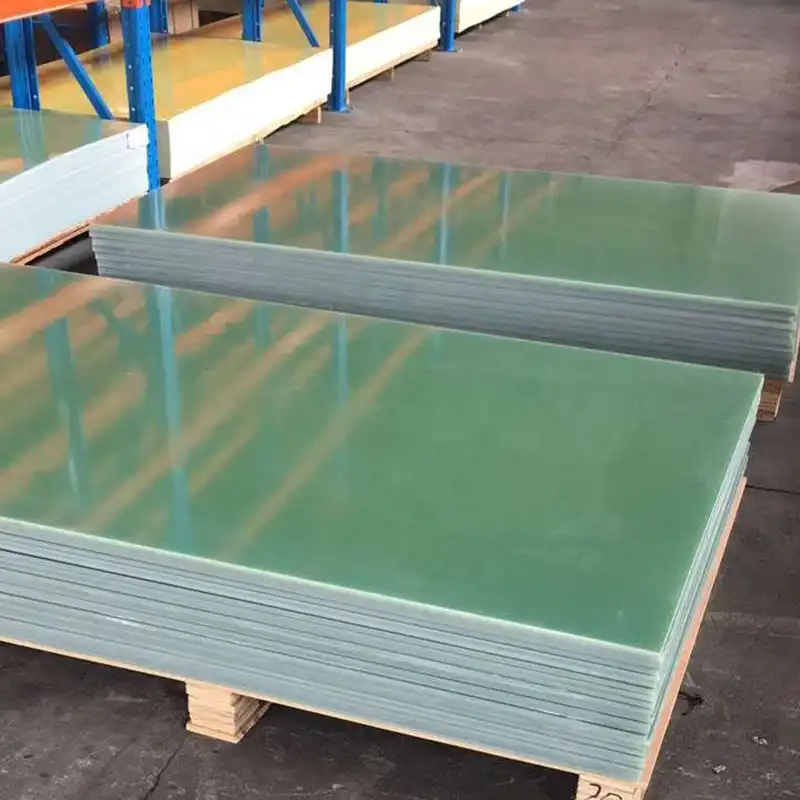

Understanding FR4 Sheet: Composition and Properties

FR4, short for Flame Retardant 4, is a composite material widely used in the electronics industry. It's primarily composed of woven fiberglass cloth impregnated with an epoxy resin binder. This combination results in a material that boasts excellent mechanical strength, electrical insulation properties, and importantly, flame resistance.

The "FR" in FR4 stands for "Flame Retardant," which gives us our first clue about its flammability characteristics. FR4 sheet is designed to resist ignition and slow the spread of flames. This property is crucial in electronic applications where heat generation and electrical sparks are common occurrences. Some key properties of FR4 include:

- High Strength-to-Weight Ratio: FR4 sheets exhibit a remarkable strength-to-weight ratio, which makes them an ideal choice for applications that require robust materials without adding excessive weight. The high strength-to-weight ratio also means that FR4 can withstand physical stress and impacts, making it a durable option for circuit boards and other electronic components.

- Excellent Electrical Insulation: One of the standout properties of FR4 is its excellent electrical insulation. The epoxy resin and fiberglass combination create a material that effectively prevents electrical currents from passing through, ensuring the safe operation of electronic circuits.

- Water Absorption: FR4 sheet's low water absorption rate is another critical property, especially in environments prone to moisture. The epoxy resin in FR4 forms a dense barrier that resists water penetration, ensuring that the material maintains its structural integrity and insulating properties even in damp conditions.

- Good Chemical Resistance: In addition to its mechanical and electrical properties, FR4 also boasts good chemical resistance. This means that the material can withstand exposure to various chemicals and solvents without degrading.

- Dimensional Stability Across a Wide Temperature Range: FR4's dimensional stability is another significant advantage. The material maintains its shape and size across a wide temperature range, which is essential for the reliability of electronic components that experience varying thermal conditions.

FR4 and Flame Resistance: What You Need to Know?

Now, let's address the burning question: Is FR4 flammable? While FR4 is not entirely non-flammable, it is highly flame-resistant. This means that while it can catch fire under extreme conditions, it doesn't ignite easily and doesn't support combustion. Understanding the nuances of FR4's flame resistance is crucial for its application in safety-critical environments, particularly in the electronics industry.

How FR4 Achieves Flame Retardancy

FR4 achieves its flame-retardant properties through the addition of specific compounds to the epoxy resin. These additives, often bromine-based, work by releasing flame-inhibiting gases when exposed to high temperatures. This process helps to suppress the spread of flames and self-extinguish the material. The bromine compounds interfere with the combustion process by capturing free radicals, which are essential for the propagation of flames, thus slowing down or stopping the fire from spreading.

Meeting Flame Resistance Standards

FR4 sheets are designed to meet stringent flame resistance standards, such as UL94 V-0. This rating is an important benchmark in the electronics industry, indicating that the material stops burning within 10 seconds after a flame is removed and doesn't produce flaming drips. Achieving a UL94 V-0 rating involves rigorous testing where the material is exposed to an open flame and observed for its response. The ability to meet this standard demonstrates FR4’s effectiveness in preventing the spread of fire, thereby enhancing the safety of electronic devices that use this material.

The Distinction Between Flame-Retardant and Fireproof

It's crucial to understand that "flame-retardant" doesn't mean "fireproof." Under sustained exposure to very high temperatures or direct flame, FR4 will eventually burn. The key advantage of FR4 is that it resists ignition and slows flame spread, providing valuable time in case of a fire. This resistance is particularly critical in scenarios where electronic components might be subject to overheating or electrical faults. By slowing down the combustion process, FR4 gives engineers and safety systems more time to respond, potentially preventing catastrophic damage and allowing for safe shutdown procedures.

Applications of FR4 Sheet: Where Flame Resistance Matters?

The flame-resistant properties of FR4 sheet make it an ideal material for various applications where fire safety is crucial. Here are some common uses:

Printed Circuit Boards (PCBs)

FR4 is the standard material for PCBs in electronics. Its flame resistance helps prevent fires in case of electrical shorts or overheating components. In electronic devices, where compact and intricate circuits are common, the risk of short circuits and overheating is always present. FR4's ability to resist ignition and self-extinguish flames adds a critical layer of safety, protecting both the device and the user.

Electrical Insulation

FR4 sheets are used as insulators in high-voltage applications, where its flame resistance adds an extra layer of safety. Electrical systems, especially those operating at high voltages, require materials that can effectively prevent electrical arcing and potential fires. FR4's combination of mechanical strength and flame resistance makes it an excellent choice for insulating components and protecting against electrical hazards.

Aerospace and Automotive

In the aerospace and automotive industries, where safety is paramount, FR4 is used for various components due to its combination of strength, light weight, and flame resistance. In aerospace, FR4 is employed in avionics, control systems, and other electronic components where failure is not an option. Its ability to withstand high temperatures and resist flames ensures that these components remain operational under extreme conditions.

Industrial Equipment

FR4 finds applications in machinery and equipment where electrical insulation and fire safety are essential. Industrial environments often involve high-power machinery and equipment that can generate significant heat. Using FR4 in such settings helps ensure that electrical components are well-insulated and protected against the risk of fire.

Military and Defense

The robust properties of FR4, including its flame resistance, make it suitable for various military applications. In defense systems, where reliability and durability are crucial, FR4 is used in communication devices, control systems, and other electronic components. The material's ability to perform under extreme conditions and resist flames provides a dependable solution for mission-critical applications.

Conclusion

In conclusion, while FR4 is not completely non-flammable, its flame-retardant properties make it a safe and reliable choice for many applications where fire safety is a concern. Its ability to resist ignition and slow flame spread, combined with its excellent electrical and mechanical properties, continues to make FR4 sheet a go-to material in the electronics industry and beyond.

If you're considering using FR4 sheet for your project or application and want to learn more about its properties and capabilities, don't hesitate to reach out to us. With over 20 years of experience in producing and selling insulating sheets, including FR4, we're here to provide you with expert advice and high-quality products. Contact us at info@jhd-material.com for more information or to discuss your specific needs.

References

1. Nolte, J. (2018). "Introduction to FR4 and its Applications." Circuit Digest.

2. Underwriters Laboratories (2020). "UL 94 Flame Classifications."

3. Foster, R. (2019). "Understanding the Properties and Uses of FR4 Material." Electronics Weekly.

4. Chung, D.D.L. (2016). "Composite Materials: Science and Applications." Springer.

5. Blazev, A. (2017). "The Performance of Flame-Retardant Materials in Electronics." IEEE Xplore.