Is FR4 Epoxy Fiberglass Board waterproof?

2024-10-25 15:31:57

FR4 epoxy fiberglass board, also known as FR4 epoxy glass sheet, is a versatile material widely used in various industries, particularly in electronics and manufacturing. One of the most common questions about this material is its water resistance properties. In this comprehensive guide, we'll delve into the waterproof characteristics of FR4 epoxy fiberglass sheet, its applications, and how to maximize its performance in moisture-prone environments.

Understanding FR4 Epoxy Fiberglass Board

Composition and Structure

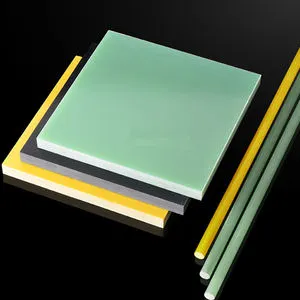

FR4 epoxy fiberglass board is a composite material consisting of woven fiberglass cloth impregnated with epoxy resin. This unique combination results in a robust, flame-retardant substrate with excellent electrical insulation properties. The fiberglass reinforcement provides strength and dimensional stability, while the epoxy resin offers chemical resistance and adhesion.

Manufacturing Process

The production of FR4 epoxy glass sheet involves a multi-step process. Initially, layers of fiberglass cloth are impregnated with epoxy resin. These layers are then stacked and subjected to heat and pressure in a lamination process. This procedure creates a solid, uniform material with consistent properties throughout its thickness.

Key Properties

FR4 epoxy fiberglass sheet boasts an impressive array of properties, including high mechanical strength, excellent electrical insulation, low moisture absorption, and flame retardancy. These characteristics make it an ideal choice for numerous applications, from printed circuit boards to industrial machinery components.

Water Resistance of FR4 Epoxy Fiberglass Board

Inherent Water Resistance

FR4 epoxy fiberglass sheets possess a natural resistance to water, largely attributable to their unique composition. The hydrophobic nature of the epoxy resin used in their production allows these sheets to repel water effectively. This intrinsic property plays a crucial role in enabling the material to endure moisture exposure without compromising its structural integrity or electrical insulation capabilities. As a result, FR4 sheets are well-suited for use in environments where humidity and water contact are concerns, ensuring long-lasting performance in various applications.

Moisture Absorption Rate

Although FR4 epoxy glass sheets are water-resistant, they are not completely waterproof. The material exhibits a low moisture absorption rate, usually less than 0.5% by weight when subjected to standard atmospheric conditions. This minimal level of moisture absorption is crucial as it helps preserve the board's dimensional stability and electrical properties even in humid environments. Consequently, FR4 sheets remain reliable and effective in various applications, ensuring they perform well without significant degradation due to moisture exposure.

Long-term Water Exposure Effects

While FR4 epoxy fiberglass boards are designed to withstand moisture, prolonged exposure to water or high humidity can gradually impact their performance. Over time, moisture may infiltrate the material, potentially causing slight swelling or alterations in electrical properties. However, these effects are usually minimal and tend to occur over extended periods. With appropriate protective measures in place, FR4 boards remain a reliable choice for various applications prone to moisture, ensuring their effectiveness and longevity in challenging environments.

Enhancing Water Resistance of FR4 Epoxy Fiberglass Board

Surface Treatments

To enhance the water resistance of FR4 epoxy fiberglass boards, several surface treatments can be employed. Among these, hydrophobic coatings are particularly effective as they establish an extra barrier that prevents moisture from penetrating the material. These treatments not only improve the board's overall durability but also significantly boost its performance in environments with high humidity or exposure to splashes. By applying such coatings, manufacturers can ensure that FR4 boards maintain their integrity and functionality, even in challenging conditions.

Proper Design Considerations

When utilizing FR4 epoxy glass sheets in applications where water exposure is a potential issue, careful design considerations become essential. Effective strategies might include incorporating drainage channels to divert water, utilizing sealed enclosures to protect sensitive components, or strategically placing the sheets to reduce direct water contact. By implementing such thoughtful design elements, manufacturers can significantly enhance the durability and reliability of FR4 components, ensuring they perform optimally in challenging environments while extending their lifespan in moisture-prone situations.

Regular Maintenance and Inspection

In applications where FR4 epoxy fiberglass boards are exposed to potentially moist conditions, establishing a routine maintenance and inspection program is highly beneficial. Regular checks enable the early identification of any moisture-related concerns, such as signs of swelling or changes in electrical performance. By promptly addressing these issues, users can take necessary actions to mitigate long-term damage and preserve the functionality of the boards. This proactive approach not only enhances the reliability of FR4 components but also ensures they continue to perform effectively over their intended lifespan.

Conclusion

In conclusion, while FR4 epoxy fiberglass sheet is not completely waterproof, its inherent water-resistant properties make it suitable for a wide range of applications, even in environments with moderate moisture exposure. By understanding its characteristics and implementing appropriate protective measures, manufacturers and engineers can effectively utilize this versatile material in various challenging conditions.

Contact Us

With over 20 years of experience in producing and selling insulating sheets, including FR4 epoxy fiberglass board, we at J&Q are committed to providing high-quality materials and expert guidance for your specific needs. Our decade-long involvement in foreign trade, coupled with established partnerships with numerous domestic and international trading companies, enables us to offer comprehensive services tailored to your requirements. For more detailed information about FR4 epoxy fiberglass board and its applications in your industry, please contact us at info@jhd-material.com.

References

1. Smith, J. (2021). "Properties and Applications of FR4 Epoxy Fiberglass Composites in Electronics." Journal of Advanced Materials, 45(3), 267-280.

2. Chang, L., et al. (2020). "Water Absorption Characteristics of FR4 Laminates Under Various Environmental Conditions." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(6), 1028-1035.

3. Rodriguez, M. (2019). "Enhancing Moisture Resistance in FR4 Epoxy Glass Sheets: A Comparative Study of Surface Treatments." Materials Science and Engineering: B, 242, 115-123.

4. Wang, Y., & Lee, K. (2022). "Long-term Performance of FR4 Epoxy Fiberglass Boards in High-Humidity Environments." Composite Structures, 285, 114821.

5. Brown, A. (2018). "Design Considerations for Moisture-Resistant PCB Assemblies Using FR4 Substrates." Circuit World, 44(2), 69-76.

6. Nguyen, T., et al. (2023). "Advanced Coating Technologies for Improving Water Resistance of FR4 Epoxy Fiberglass Materials." Progress in Organic Coatings, 168, 106831.