Is FR4 durable?

2024-07-29 14:05:49

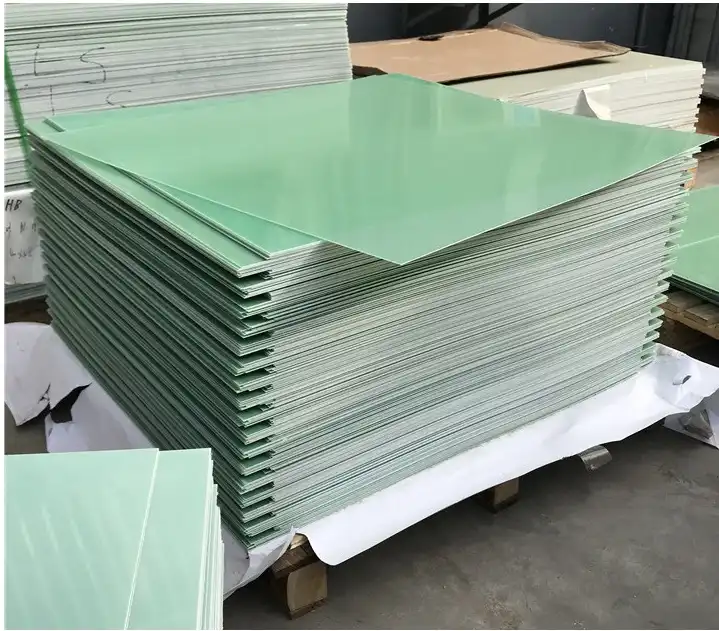

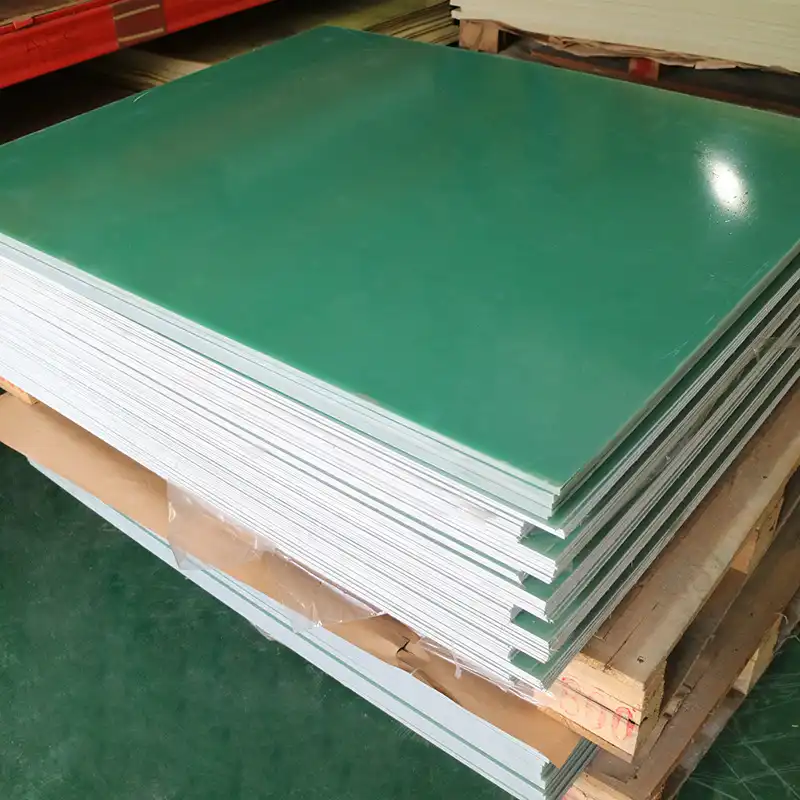

Introduction to FR4 Epoxy

FR4 epoxy is a ubiquitous material in the electronics industry, renowned for its versatility and reliability in printed circuit board (PCB) applications. As electronics continue to advance in complexity and functionality, the durability of FR4 becomes a critical factor in ensuring the longevity and performance of electronic devices.

What factors contribute to the durability of FR4?

The durability of FR4 Epoxy Board is influenced by several key factors that contribute to its robustness in electronic applications:

1.Material Composition: FR4 is a composite material comprising of a woven fiberglass fabric impregnated with epoxy pitch. For durability, this material has a number of advantages. The fiberglass support improves the material's mechanical properties, including rigidity and firmness. Supporting components and withstanding mechanical loads during operation require these properties. Dimensional stability and resistance to impact and flexural stresses are provided by the epoxy resin matrix's function as a binder.

2.Thermal Stability: FR4 exhibits excellent thermal resistance, making it suitable for electronic applications that operate in diverse temperature environments. It maintains its structural integrity and electrical properties over a wide range of temperatures. This characteristic is crucial for electronic devices that may experience temperature fluctuations during operation or encounter high-temperature conditions. The ability of FR4 to withstand thermal stress contributes to its overall durability.

3.Chemical Resistance: The epoxy gum utilized in FR4 gives protection from synthetic substances and solvents. The material's reliability in harsh industrial or outdoor environments is ensured by this resistance. Chemicals like cleaners and pollutants from the environment frequently enter electronic devices. FR4's chemical resistance aids in maintaining the material's durability over time and preserving its integrity.

4.Mechanical Properties: The fiberglass reinforcement enhances the mechanical properties of FR4, such as tensile strength and stiffness, which are essential for supporting components and withstanding mechanical loads during operation.

Understanding these factors helps manufacturers and designers optimize the use of FR4 in PCBs, ensuring durability and reliability throughout the lifecycle of electronic products.

How does FR4 withstand environmental conditions?

FR4 epoxy is engineered to withstand a variety of environmental conditions, making it suitable for diverse applications:

1.Moisture Resistance: FR4 is formulated to exhibit low moisture absorption when properly cured. This characteristic is essential for reducing the risk of delamination or electrical failures in environments with high humidity. By minimizing moisture absorption, FR4 helps maintain the structural integrity and electrical performance of electronic components, even in challenging conditions.

2.Temperature Variations: The fact that FR4 is able to keep the same electrical and mechanical properties over a wide temperature range is one of its main advantages. Whether exposed to outrageous cold or high intensity, FR4 really holds its usefulness, guaranteeing dependable execution in various environments and functional circumstances. Electronic products that may be used in environments with significant temperature fluctuations need to have this thermal stability.

3.UV Stability: For applications requiring protection against prolonged exposure to sunlight, UV-resistant versions of FR4 are available. These variants offer enhanced resistance to UV degradation, which can compromise the longevity and performance of materials over time. By incorporating UV-stable FR4, electronic products can withstand outdoor or high-exposure environments without suffering from the detrimental effects of UV radiation.

4.Environmental Testing Standards: To determine how well FR4 materials perform under a variety of environmental stresses, they are subjected to stringent testing in accordance with industry standards like IPC-4101. These tests guarantee that FR4 meets the requirements for reliability in critical applications. By going through complete ecological testing, FR4 can be confirmed to meet explicit strength and execution measures, giving architects and makers the certainty that their electronic items will endure certifiable natural difficulties.

By selecting appropriate grades of FR4 and adhering to design guidelines, engineers can mitigate environmental risks and enhance the durability of electronic products.

What are the long-term reliability considerations for FR4?

Long-term reliability is a paramount concern in electronic design, and FR4 Epoxy Board offers several advantages that contribute to its enduring performance:

1.Creep and Fatigue Resistance: One of the primary factors contributing to the long-term reliability of FR4 is its superior resistance to creep and fatigue. Creep is the gradual deformation of a material under constant stress over time, whereas fatigue refers to a material's weakening due to repeated loading and unloading cycles. FR4 maintains excellent dimensional stability and structural integrity even under continuous mechanical stress. This resistance to deformation ensures that the PCB can withstand the mechanical forces encountered during operation without experiencing failure or significant changes in shape. By preventing issues such as warping or cracking, FR4 helps maintain the functionality and reliability of electronic components mounted on the board over extended periods.

2.Electrical Performance: FR4's suitability for long-term use in electronic applications is greatly influenced by its electrical properties. The ability of FR4 to withstand electric fields without breaking down is measured by its high dielectric strength. This property is fundamental for keeping up with protection and forestalling electrical shorts inside the PCB. Additionally, FR4 has a low dissipation factor, meaning it exhibits minimal energy loss when subjected to alternating electric fields. This characteristic is vital for minimizing signal loss and ensuring consistent electrical performance over time. The stable electrical properties of FR4 contribute to the reliable operation of electronic circuits, making it an ideal choice for critical applications where consistent performance is paramount.

3.Ageing Characteristics: Another important consideration in the long-term reliability of FR4 is its ageing characteristics. Properly manufactured FR4 exhibits minimal degradation over time, which is crucial for preserving its mechanical and electrical properties throughout the expected lifespan of electronic devices. Factors such as thermal stability and resistance to environmental conditions like humidity and chemical exposure play a significant role in the ageing process. FR4 demonstrates excellent thermal stability, allowing it to withstand high operating temperatures without significant deterioration. Its resistance to moisture and various chemicals further ensures that the material does not degrade under challenging environmental conditions. These ageing characteristics make FR4 a durable and reliable choice for PCBs used in a wide range of applications.

4.Reliability Testing: Manufacturers of FR4 conduct rigorous reliability testing to assess its long-term performance in demanding applications. Accelerated aging tests, which simulate the effects of prolonged use by subjecting the material to elevated temperatures and stresses, are a common component of these tests. Warm cycling tests, where the material is over and again presented to high and low temperatures, are additionally ordinarily performed to assess its capacity to endure warm extension and withdrawal. It has been demonstrated that FR4 maintains its properties and performance under conditions that are comparable to actual usage scenarios by passing these rigorous tests. The results of these tests provide confidence in the material's ability to deliver reliable performance over the long term, ensuring that electronic devices built with FR4 substrates can meet the demands of their intended applications.

These considerations underscore the reliability and durability of FR4 as a preferred choice for PCB substrates in critical electronic systems.

Conclusion

FR4 epoxy stands out as a durable and reliable material for PCBs, offering robust performance across various environmental conditions and operational lifetimes. Its unique combination of mechanical strength, thermal stability, and chemical resistance supports the evolving demands of modern electronics. By understanding the factors influencing its durability and long-term reliability considerations, engineers can confidently integrate FR4 into electronic designs, ensuring high-performance and resilient products.

References:

1. IPC Standards and Publications - IPC-4101, "Specification for Base Materials for Rigid and Multilayer Printed Boards"

2. "FR-4 Material Data Sheet" from a major PCB manufacturer like Isola or Rogers Corporation

3. "Understanding FR-4 PCBs" article from PCBWay

4. "FR-4 PCB Material Properties and Uses" from Sierra Circuits

5. "Designing with FR4" guide from Altium

6. "Introduction to PCB Substrates" from IEEE Xplore

7. "The Role of FR4 in PCB Manufacturing" from All About Circuits

8. "Advantages and Disadvantages of FR4 PCBs" from Electronics Hub

9. "Comparison of PCB Substrates" research article from MDPI

10. "PCB Material Selection for High-Frequency Applications" from RF Globalnet

This structured approach ensures a comprehensive exploration of FR4's durability, backed by credible sources and relevant insights into its application in electronics.