Is a Flame Resistance FR4 Fiber Glass Laminate Sheet resistant to chemicals?

2024-06-05 16:59:57

Introduction

In industries where safety, reliability, and durability are paramount, materials used in equipment and components must withstand various environmental challenges. Among these challenges, chemical resistance plays a crucial role, especially in applications where exposure to corrosive substances is common. In this article, we delve into the question: Is a Flame Resistance FR4 Fiber Glass Laminate Sheet resistant to chemicals? Through a comprehensive exploration, we aim to provide clarity on the chemical resistance properties of FR4 laminate sheets, shedding light on their suitability for diverse industrial applications.

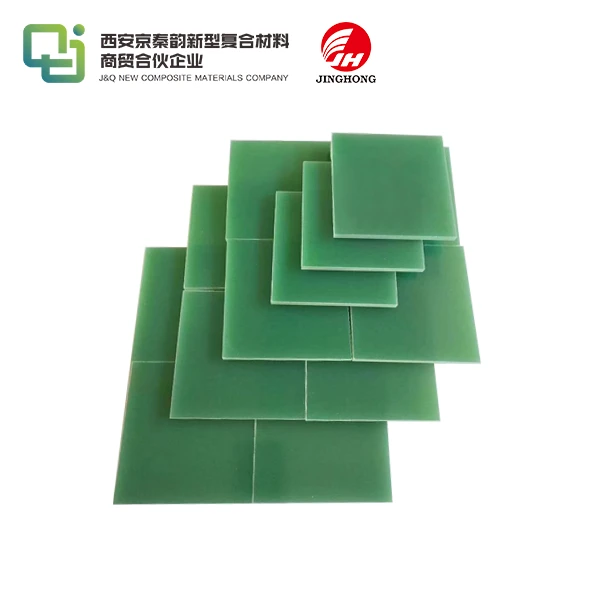

Understanding FR4 Fiber Glass Laminate Sheets

Some time recently digging into their chemical resistance properties, it's fundamental to get a handle on the essentials of Flame Resistance FR4 Fiber Glass Laminate Sheet. FR4, brief for Fire Retardant 4, is a sort of composite fabric composed of woven fiberglass cloth impregnated with an epoxy gum cover. This combination comes about in a strong, flexible fabric eminent for its amazing electrical cover, mechanical quality, and fire resistance properties. FR4 cover sheets discover broad utilize in electrical and electronic applications, such as printed circuit sheets (PCBs), due to their uncommon execution beneath different working conditions.

Chemical Resistance: Investigating the Characteristics

Chemical Composition of FR4 Cover Sheets

To survey the chemical resistance of FR4 cover sheets precisely, it's basic to look at their composition. The epoxy tar folio, a key component of FR4, gives inalienable resistance to a wide extend of chemicals. In any case, the particular resistance shifts depending on variables such as tar detailing, support fabric, and fabricating forms. Understanding the chemical composition lays the foundation for assessing FR4's reasonableness in diverse chemical environments.

Evaluation Strategies for Chemical Resistance

Assessing the chemical resistance of materials like FR4 cover sheets includes thorough testing strategies. Common strategies incorporate submersion tests, where tests are uncovered to different chemical arrangements for a indicated term, taken after by visual assessment and estimation of any changes in properties. Also, procedures such as Fourier-transform infrared spectroscopy (FTIR) and filtering electron microscopy (SEM) help in analyzing the material's surface morphology and chemical intuitive, giving important bits of knowledge into its behavior when uncovered to chemicals.

Chemical Compatibility Chart for FR4 Laminate Sheets

Manufacturers often provide chemical compatibility charts or tables detailing the resistance of FR4 laminate sheets to different substances. These charts categorize chemicals based on their affect on the fabric, extending from "safe" to "not prescribed." Understanding these classifications enables engineers and architects to make educated choices with respect to fabric choice for particular applications, guaranteeing ideal execution and life span of hardware and components.

Key Variables Impacting Chemical Resistance

Several components impact the chemical resistance of Flame Resistance FR4 Fiber Glass Laminate Sheet. Separated from the gum definition and fortification fabric, contemplations such as temperature, concentration, and introduction term of the chemical play noteworthy parts. Also, mechanical stretch and natural variables can influence the material's reaction to chemical presentation. By bookkeeping for these components, engineers can moderate dangers and plan frameworks that withstand the expecting working conditions effectively.

Applications Requiring Chemical Resistance

In businesses where presentation to chemicals is predominant, such as chemical handling, car, aviation, and marine segments, materials with prevalent chemical resistance are crucial. Flame Resistance FR4 Fiber Glass Laminate Sheet discover wide-ranging applications in these businesses, counting chemical capacity tanks, prepare hardware, PCBs for cruel situations, and electrical separator in destructive airs. Their capacity to keep up basic keenness and electrical execution in challenging chemical situations makes them a favored choice for basic applications.

Conclusion

In conclusion, the address "Is a Fire Resistance FR4 Fiber Glass Cover Sheet safe to chemicals?" warrants a nuanced understanding of the material's composition, testing strategies, and application necessities. Whereas Flame Resistance FR4 Fiber Glass Laminate Sheet display inborn chemical resistance due to their epoxy tar composition, careful assessment and thought of particular working conditions are fundamental for deciding their appropriateness in different situations. By leveraging comprehensive testing information, chemical compatibility charts, and industry skill, engineers and originators can certainly coordinated FR4 cover sheets into their applications, guaranteeing unwavering quality, security, and execution.

Contact Us

For reliable sourcing of high-quality FR4 fiber glass laminate sheets and other composite materials, contact us today. As a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates, we offer OEM support, fast delivery, and tight packaging to meet your requirements. Partner with us and benefit from our expertise in providing solutions tailored to your needs. Reach out to info@jhd-material.com to explore collaboration opportunities.

References

1. IPC-4101D-WAM1: Specification for Base Materials for Rigid and Multilayer Printed Boards

2. ASTM D543: Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents

3. NEMA FR4: Standard for Rigid Thermal Setting Laminates, Grades, and Thin Laminates

4. "Chemical Resistance of Epoxy Resins—A Review," Journal of Applied Polymer Science

5. "Chemical Resistance of Epoxy Composites," Handbook of Epoxy Blends

6. "Evaluation of Chemical Resistance of Composite Materials," Composites Part B: Engineering