Are Epoxy Resin Sheets suitable for outdoor use?

2024-07-30 17:20:41

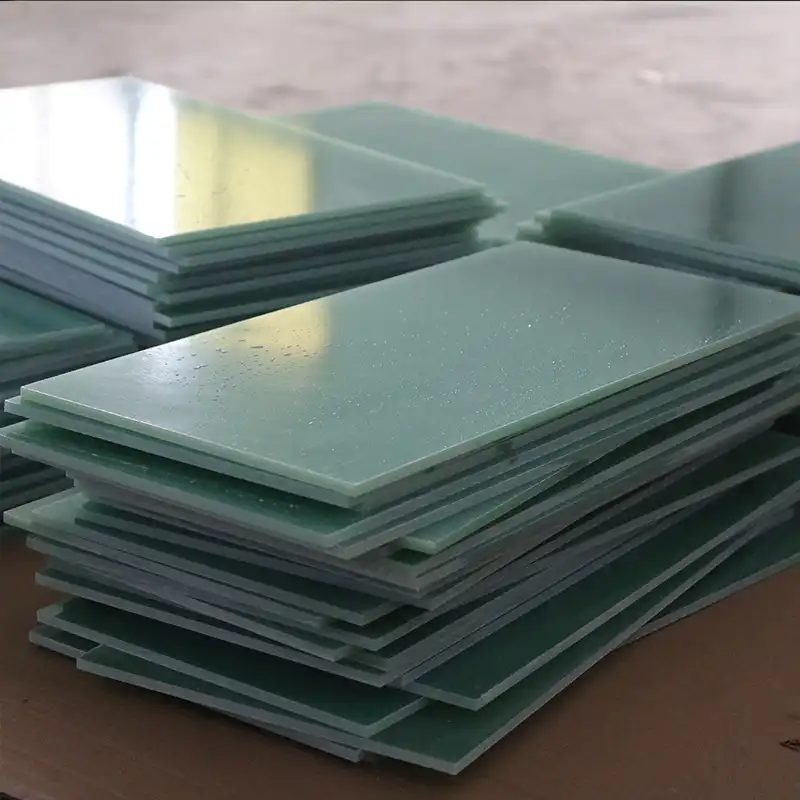

Epoxy resin sheets are popular for various applications due to their durability and versatility. However, when it comes to outdoor use, there are specific considerations and modifications needed to ensure their effectiveness and longevity. This blog will explore whether epoxy resin sheets are suitable for outdoor use by addressing three key questions:

Can Epoxy Resin Withstand Outdoor Weather Conditions?

Epoxy Resin Sheets is known for its robust and durable nature, making it an excellent choice for many indoor applications. However, using epoxy resin outdoors presents unique challenges. One of the main concerns is its reaction to weather conditions, including exposure to sunlight, temperature fluctuations, and moisture.

Epoxy resin can withstand moderate weather conditions when properly applied and cured. It is waterproof, which makes it resistant to rain and humidity. However, extreme temperatures can affect its performance. For instance, very high temperatures can cause the resin to soften, while freezing temperatures can lead to brittleness and cracking. This variability necessitates choosing the right type of epoxy for specific outdoor conditions.

Another factor to consider is the expansion and contraction of materials. For example, if epoxy is applied over wood, temperature changes can cause the wood to expand and contract, potentially leading to cracking or delamination of the epoxy coating. This issue is less pronounced with materials that have similar thermal expansion properties, such as concrete or metal.

To mitigate these challenges, it's crucial to use an epoxy resin formulated for outdoor use. These formulations often include UV inhibitors and other additives that enhance their resistance to weathering. For instance, products like UVPoxy are designed specifically to withstand the rigors of outdoor environments, providing a longer-lasting finish.

How Do You Protect Epoxy Resin from UV Damage?

One of the significant challenges of using Epoxy Resin Sheets outdoors is its susceptibility to UV damage. Prolonged exposure to sunlight can cause epoxy to yellow, fade, and degrade over time. This is because standard epoxy resins do not have inherent UV resistance.

To protect epoxy resin from UV damage, several strategies can be employed:

1. UV-Resistant Epoxy Formulations: When selecting epoxy products for outdoor applications, it is crucial to choose those specifically designed for such conditions, as they include UV inhibitors. These specialized epoxies are formulated to withstand the harsh effects of prolonged sun exposure, effectively resisting yellowing and maintaining their clarity and structural integrity over time. The UV inhibitors play a significant role in protecting the epoxy from the damaging ultraviolet rays, ensuring that the surface remains clear and durable. By opting for these high-quality products, you can achieve long-lasting results that not only look great but also provide reliable performance in outdoor environments. This careful selection will ensure that your projects endure the elements while retaining their aesthetic appeal and strength.

2. Adding UV Inhibitors: By incorporating UV inhibitors into the mixture, you can improve the standard epoxy resin's resistance to sunlight if you already have it. Blending in UV inhibitors permits you to modify the epoxy as per your particular necessities, giving added security against the harming impacts of UV beams. This approach demonstrates gainful when you need to use the epoxy in outside applications where openness to daylight is unavoidable. You can guarantee that your epoxy coating will remain durable and visually appealing for an extended period of time even when exposed to direct sunlight by taking this proactive step.

3. Top Coats and Sealants: Adding a defensive top coat, for example, polyurethane, over the epoxy tar offers an additional layer of UV defending. Polyurethane coatings are prestigious for their extraordinary UV obstruction, actually safeguarding the visual allure and primary honesty of the hidden epoxy layer. This extra defensive measure altogether diminishes the effect of UV beams on the epoxy, drawing out its life expectancy and keeping up with its unique appearance. By adding polyurethane, you create a strong barrier against sun-induced deterioration, ensuring that your epoxy surface remains vibrant and long-lasting even when exposed to prolonged direct sunlight. This strategy improves the general life span and execution of the epoxy covering in open air settings.

4. Color Choices: Opting for darker or UV-stable colors when choosing epoxy for your projects can serve as a strategic approach to concealing potential yellowing or fading, effectively preserving the visual allure over time. By selecting darker hues or UV-stable colorants, you can mitigate the impact of UV exposure, reducing the visibility of any discoloration that may occur. This proactive decision ensures that your epoxy projects maintain their aesthetic appeal, even in outdoor settings with prolonged sun exposure. The careful selection of colors plays a pivotal role in minimizing the effects of UV rays, contributing to a long-lasting and visually pleasing outcome for your epoxy applications.

What Are the Best Practices for Using Epoxy Resin Outdoors?

Using Epoxy Resin Sheets outdoors successfully requires following best practices to ensure durability and longevity. Here are some key tips:

1. Proper Surface Preparation: This preparatory step is necessary for professional-looking adhesion and a smooth finish. Surfaces contaminated with dust, grease, oil, or moisture can hinder the epoxy's ability to bond properly, leading to coating flaws or potential failures. Clean the surface completely with the fitting cleaning items and permit it to dry totally to set it up. The epoxy application's sturdiness and tasteful quality will be essentially improved in the event that you require some investment to play out this fundamental readiness, bringing about an impeccable and dependable completion.

2. Controlled Application Environment:

When applying epoxy resin, it is crucial to work in a sheltered area to protect the surface from debris, dust, and insects during the curing process. This precaution helps ensure a smooth, flawless finish. Ideally, the application should take place when the weather is stable, as significant fluctuations in temperature and humidity can adversely affect the curing and final quality of the epoxy. Choosing a day with consistent weather conditions will help the resin cure evenly and reduce the risk of imperfections. Proper preparation and environmental control are essential for achieving the best results with epoxy resin applications.

3. Layering and Curing: When applying epoxy resin, it is essential to do so in thin, even layers. Each layer should be allowed to cure fully before the next one is added. This methodical approach helps prevent common issues such as bubbling, cracking, or incomplete curing that can compromise the integrity and appearance of the finished product. By ensuring that each layer is properly cured, you create a strong, durable bond between layers. This procedure not just upgrades the general strength and toughness of the epoxy covering yet in addition guarantees a smooth, proficient completion. Patience and careful application are key to achieving optimal results with epoxy resin.

4. Regular Maintenance: Keeping up with outside epoxy surfaces is vital to guarantee they stay in ideal condition after some time. Cleaning the surface thoroughly removes dirt, debris, and any potential contaminants that could compromise its integrity as part of routine maintenance. Additionally, it is essential to reapply protective top coats on a regular basis to safeguard against environmental factors like moisture, UV rays, and temperature variations. In order to catch any signs of wear, damage, or deterioration early on, regular inspections are also necessary. Resolving these issues immediately can forestall greater issues and expand the life expectancy of the epoxy surface, guaranteeing it proceeds to look and perform at its ideal.

5. Consider Alternative Coatings: In some cases, alternative coatings such as polyaspartic or polyurea might be more suitable for outdoor applications. These coatings offer superior UV resistance, flexibility, and durability compared to traditional epoxy, making them ideal for high-traffic and exposed areas.

In conclusion, epoxy resin sheets can be suitable for outdoor use if the correct formulations and protective measures are employed. By understanding the challenges and implementing best practices, you can achieve durable and aesthetically pleasing results for your outdoor epoxy projects.

References

1. [Meaningful Spaces](https://www.meaningfulspaces.com)

2. [Everlast Concrete Coatings](https://www.everlastconcretefloor.com)

3. [Salvage Secrets](https://www.salvagesecretsblog.com)

4. [ResinPassion](https://www.resinpassion.com)

5. [Industrial Clear](https://www.industrialclear.com)

6. [Epoxy Flooring Tech](https://www.epoxyflooringtech.com)

7. [Resin Obsession](https://www.resinobsession.com)

8. [Salvage Secrets](https://www.salvagesecretsblog.com)

9. [Resin Obsession](https://www.resinobsession.com)

10. [Epoxy Flooring Tech](https://www.epoxyflooringtech.com)