Introduction to Epoxy Floor Coating

2023-11-23

1. What is Epoxy Floor Coating?

Epoxy floor coating(Epoxy Resin For Floor) is a highly attractive and durable type of flooring paint. In the late 20th century, many cleanroom floors appeared in Europe and America, which used integral polymer surface layers known as epoxy floor coatings, primarily composed of epoxy resin and curing agents.

2. Classification of Epoxy Floor Coating(Epoxy Resin For Floor):

①. Solvent-based Epoxy Resin Floor Coating: This type of coating is suitable for areas that require high wear resistance, corrosion resistance, oil resistance, heavy load resistance, smooth surfaces, and easy cleaning. It is commonly used in places such as parking lots, automobile manufacturing, machinery manufacturing, paper mills, cigarette factories, chemical industry, textile industry, and furniture production workshops. Solvent-based epoxy resin floor coatings have the following advantages: seamless and easy to clean, no dust or bacteria accumulation; smooth and flat surface with a wide range of colors, enhancing the work environment aesthetics; non-toxic and meeting hygiene requirements; providing slip resistance as parking lot floors require certain roughness, which is difficult to achieve with regular cement floors.

②. Solvent-free Epoxy Resin Floor Coating: This type of coating is a highly clean and decorative material for flooring. It has a smooth and clean surface and can meet high cleanliness requirements. It is widely used in industries such as pharmaceuticals, food, electronics, precision instruments, and automobile manufacturing that have strict demands on the floor. Solvent-free epoxy resin floor coatings have the following advantages: high adhesion strength to the base, low shrinkage during curing, minimizing cracks; seamless and easy to clean, no dust or bacteria accumulation; high solid content, achieving a thick film in one application; solvent-free, low toxicity during construction, environmentally friendly; high strength, wear resistance, long-lasting durability against forklifts, trolleys, and other vehicles; resistance to penetration and strong resistance to chemical corrosion, as well as good tolerance to oils; easy maintenance with room temperature curing; smooth and flat surface with a wide range of colors, enhancing the work environment aesthetics; non-toxic and meeting hygiene requirements.

3.The advantages of epoxy floor paint(Epoxy Resin For Floor)are as follows:

①. Excellent adhesion: Epoxy floor coatings contain numerous hydroxyl and ether bonds, allowing them to adhere well to substrates. Additionally, epoxy resin exhibits low volume shrinkage (around 2%) during curing, resulting in excellent adhesion to polar substrates such as metals (steel, aluminum), ceramics, glass, concrete, and wood.

②. Excellent chemical resistance: Epoxy resin contains only hydrocarbon and ether bonds, lacking ester bonds, which makes it particularly resistant to alkalis. This property enables its use as anti-corrosion primer in environments prone to alkali corrosion. Furthermore, the three-dimensional network structure formed after curing enables resistance to oil immersion, making it suitable for anti-corrosion applications in oil tanks, oil tankers, and aircraft fuel tank linings.

③. Good toughness: Compared to thermosetting phenolic resin coatings, epoxy floor coatings exhibit good toughness due to the presence of aromatic rings and flexible ether bonds that allow molecular chain rotation. In contrast, phenolic resins are brittle due to their shorter cross-linking distances. The longer cross-linking distances in epoxy resins facilitate internal rotation, and higher molecular weight results in larger cross-linking distances.

④. Epoxy resin exhibits a certain wetting ability on damp surfaces, especially when used with polyamide resins as curing agents, enabling underwater application by displacing surface water. This property is beneficial for emergency repairs and anti-corrosion coating on underwater structures.

⑤. Epoxy resin's relatively low molecular weight enables the formulation of solvent-free, high solids content powder coatings and water-based coatings, meeting environmental requirements and producing thick film coatings.

⑥. Epoxy resin contains both epoxide and hydroxyl functional groups, allowing for compatibility with various curing agents, such as polyamines, polyamide resins, phenolic resins, amino resins, and polyisocyanates, to produce coatings suitable for ambient temperature drying or high-temperature baking, meeting diverse construction requirements.

⑦. Epoxy resin possesses excellent electrical insulation properties and can be used for potting, sealing, and impregnating varnishes. However, epoxy resin is susceptible to poor light aging. The presence of aromatic ether bonds in epoxy resin makes the coating susceptible to degradation and chain breakage upon exposure to sunlight (UV radiation), leading to poor outdoor weatherability. Therefore, typical bisphenol A-based epoxy resins are not suitable for outdoor use, as their coatings are prone to loss of gloss, discoloration, and subsequent powdering.

Overall, epoxy resin offers many advantages, but it also has limitations, particularly in terms of outdoor weatherability due to poor light aging characteristics.

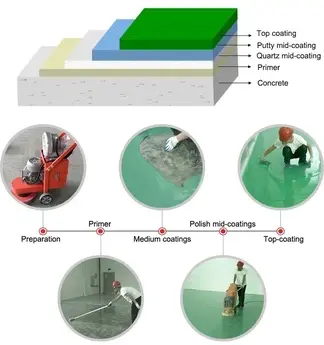

4.Epoxy Floor Coating(Epoxy Resin For Floor)Construction Process:

①. Substrate preparation: Remove loose layers, delamination, and cement residue by grinding to make the surface hard, flat, and to increase adhesion between the floor coating and the ground.

②. Primer coating: Mix the epoxy sealing primer and apply it using a roller, trowel, or brush to fully wet the concrete and penetrate into the inner layer.

③. Intermediate coating: Mix the intermediate coating material with an appropriate amount of quartz sand, and use a trowel to apply a certain thickness of smooth and compact layer.

④. Surface coating patching: Use surface coating material mixed with fine quartz powder to fill the gaps between the larger particles of the intermediate coating. After complete solidification, use a dust-free sander to polish the surface and then vacuum to remove dust and level the surface.

⑤. Surface coating application: Mix epoxy color paint with curing agent and apply it using a trowel, brush, roller, or sprayer to achieve a smooth and uniform surface coating.

5.Epoxy Floor Maintenance:

①. After the floor construction is completed, it needs to be cured for 7-10 days before being put into use. During the curing period, avoid water or other solutions from soaking the surface.

②. All personnel entering the workshop must change into rubber-soled shoes (foam-soled dark shoes are not allowed) to prevent bringing in dirt that could scratch the floor.

③. Hard items such as iron chairs, tables, and shelves should have their feet wrapped in soft plastic or rubber, or padded with paper to prevent scratching the floor during use.

④. When using a tractor, ensure that the machine board is fully lifted from the ground, especially when turning to avoid scratching the floor with the machine board corners.

⑤. Use a soft, highly absorbent mop or a dual-purpose vacuum cleaner for cleaning the floor. Clean with water or detergent, but be cautious of slippery surfaces.

⑥. In case of wear or scratches due to prolonged use, minor localized repairs can be carried out. For larger areas, it is recommended to reapply the coating.

⑦. Place hard cardboard under equipment before entering the factory to prevent scratching the floor during equipment transportation.

⑧. Use hard or elastic rubber wheels for carts and trolleys, and separate their use inside and outside the factory building.

⑨. Waxing treatment can be performed according to floor requirements (its effect can prevent floor scratches).

.webp)