How To Choose Pcb Laminate Material?

2024-11-26 17:03:33

Selecting the right PCB laminate material is crucial for ensuring the performance, reliability, and longevity of your electronic devices. With a myriad of options available in the market, making an informed decision can be challenging. This comprehensive guide will walk you through the essential factors to consider when choosing PCB laminate material, helping you make the best choice for your specific application.

Understanding PCB Laminate Materials

PCB laminate materials serve as the foundation for printed circuit boards, providing mechanical support and electrical insulation. These materials are typically composed of a reinforcement fabric, such as fiberglass, impregnated with a resin system. The choice of laminate material significantly impacts the board's electrical, thermal, and mechanical properties.

Types of PCB Laminate Materials

There are various types of PCB laminate materials available, each with unique characteristics suited for different applications. Some common types include:

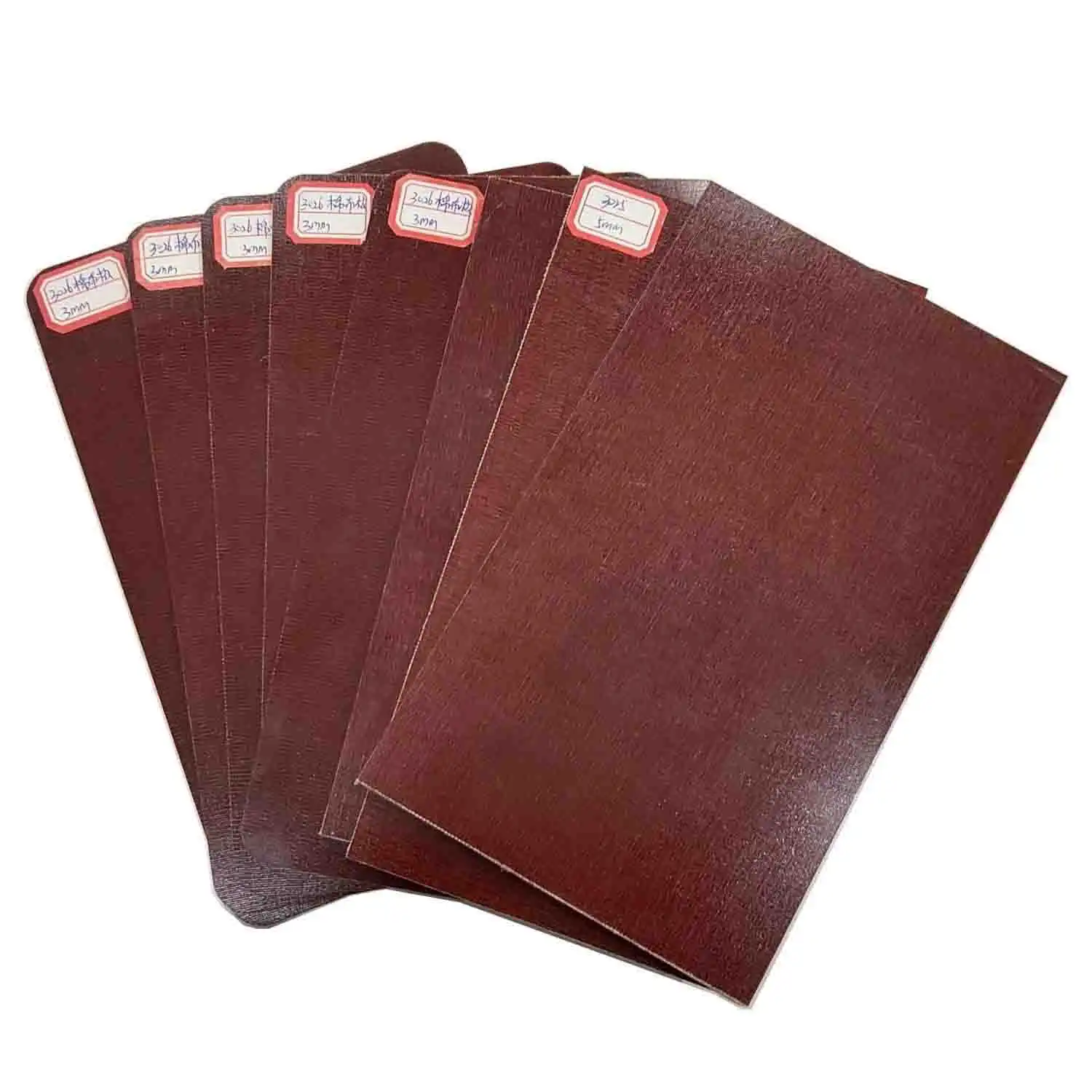

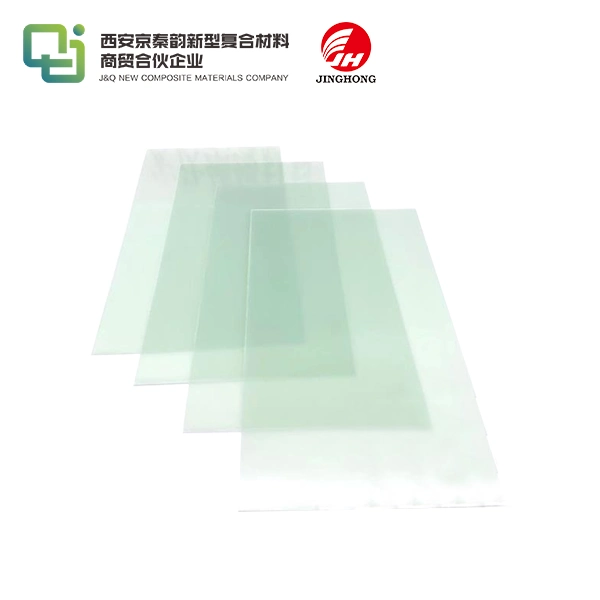

- FR-4 (Flame Retardant 4): A widely used glass-reinforced epoxy laminate

- Rogers: High-frequency laminates for RF and microwave applications

- Polyimide: Heat-resistant laminates for high-temperature environments

- PTFE (Polytetrafluoroethylene): Low-loss materials for high-frequency applications

- CEM (Composite Epoxy Material): Cost-effective alternatives to FR-4

Key Properties of PCB Laminates

When evaluating PCB laminate materials, consider the following key properties:

- Dielectric constant (Dk): Affects signal propagation and impedance

- Dissipation factor (Df): Influences signal loss and heat generation

- Thermal conductivity: Determines heat dissipation capabilities

- Coefficient of Thermal Expansion (CTE): Affects dimensional stability

- Glass transition temperature (Tg): Indicates temperature resistance

- Moisture absorption: Impacts electrical performance and reliability

Industry Standards and Certifications

Familiarize yourself with industry standards and certifications relevant to PCB laminate materials, such as:

- IPC-4101: Specification for Base Materials for Rigid and Multilayer Printed Boards

- UL 94: Standard for Safety of Flammability of Plastic Materials

- RoHS (Restriction of Hazardous Substances): Compliance for environmental safety

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): European Union regulation for chemical safety

Factors to Consider When Choosing PCB Laminate Material

Selecting the appropriate PCB laminate material involves considering various factors that impact the performance and reliability of your electronic devices. Let's explore the key considerations to help you make an informed decision.

Application Requirements

The intended application of your PCB plays a crucial role in determining the most suitable laminate material. Consider the following aspects:

- Operating frequency: High-frequency applications demand laminates that maintain stability and low signal loss over a wide range of frequencies.

- Power requirements: For high-power systems, materials must efficiently dissipate heat to prevent overheating and ensure consistent performance.

- Environmental conditions: Materials should be chosen based on their ability to withstand varying temperature ranges, humidity levels, and exposure to chemicals.

- Mechanical stress: Certain applications require materials that offer both flexibility and durability to withstand constant stress and physical wear.

Electrical Performance

Evaluate the electrical properties of laminate materials to ensure they meet your design specifications:

- Dielectric constant (Dk): Low Dk materials minimize signal delay, ensuring faster data transmission in high-speed electronic circuits.

- Dissipation factor (Df): A low Df reduces energy loss as heat, improving the overall efficiency and reliability of the system.

- Insulation resistance: High insulation resistance prevents unwanted current flow, ensuring better protection against electrical leakage and short circuits.

- Breakdown voltage: A high breakdown voltage ensures the material can tolerate high electrical stress without experiencing insulation failure.

Thermal Management

Proper thermal management is essential for maintaining the reliability and performance of electronic devices. Consider these thermal properties:

- Thermal conductivity: Materials with high thermal conductivity efficiently transfer heat, preventing overheating and enhancing performance.

- Glass transition temperature (Tg): Materials with high thermal conductivity efficiently transfer heat, preventing overheating and enhancing performance.

- Coefficient of Thermal Expansion (CTE): Lower CTE values reduce the risk of cracking or warping due to temperature fluctuations.

- Thermal decomposition temperature: This temperature indicates the point at which a material starts to degrade, ensuring its reliability under extreme heat conditions.

Advanced Considerations for PCB Laminate Selection

As technology advances and applications become more demanding, additional factors come into play when selecting PCB laminate materials. Let's explore some advanced considerations to ensure you choose the best material for your specific needs.

High-Frequency Performance

For high-frequency applications, such as 5G telecommunications or radar systems, consider these factors:

- Low dielectric loss tangent: Minimizes signal attenuation at high frequencies

- Consistent dielectric constant across frequencies: Ensures predictable performance

- Low moisture absorption: Reduces variability in electrical properties

- Smooth copper foil: Minimizes skin effect losses at high frequencies

Reliability and Longevity

To ensure the long-term reliability of your PCBs, consider these aspects:

- Thermal cycling resistance: Ability to withstand repeated temperature changes

- Moisture sensitivity level (MSL): Indicates resistance to moisture-induced damage

- Time to delamination: Measures resistance to layer separation under stress

- Solder joint reliability: Ensures robust connections during thermal cycling

Manufacturing and Processing Considerations

The choice of laminate material can impact manufacturing processes and costs:

- Drill-ability: Ease of creating holes and vias in the material

- Copper adhesion: Strength of bond between copper foil and laminate

- Dimensional stability: Ability to maintain shape during processing

- Chemical resistance: Withstands exposure to chemicals during manufacturing

Conclusion

Choosing the right PCB laminate material is a critical decision that impacts the performance, reliability, and cost-effectiveness of your electronic devices. By carefully considering factors such as application requirements, electrical performance, thermal management, and advanced considerations, you can select the optimal laminate material for your specific needs. Remember to balance performance requirements with cost constraints and consult with experts when necessary to ensure the best outcome for your PCB design.

Contact Us

Ready to find the perfect PCB laminate material (FR4 sheet, G10 sheet, 3240 epoxy sheet) for your project? Contact our team of experts at info@jhd-material.com for personalized guidance and high-quality insulating sheet solutions. Let us help you make the best choice for your PCB design needs!

References

1. Johnson, R. W., & Tummala, R. R. (2020). Materials for Advanced Packaging. Springer Nature.

2. Coombs, C. F. (2018). Printed Circuits Handbook. McGraw-Hill Education.

3. Gupta, T. K. (2019). Copper Interconnects: From Printed Circuit Boards to ICs. Springer.

4. IPC-4101D: Specification for Base Materials for Rigid and Multilayer Printed Boards. (2018). IPC - Association Connecting Electronics Industries.

5. Jillek, W., & Yung, W. K. C. (2017). Embedded components in printed circuit boards: a processing technology review. International Journal of Advanced Manufacturing Technology, 91(1-4), 1803-1832.

6. Tong, X. C. (2016). Advanced Materials for Thermal Management of Electronic Packaging. Springer.