How Electrical Insulation Phenolic Resin Cotton Fabric Enhances Safety?

2025-04-08 17:26:31

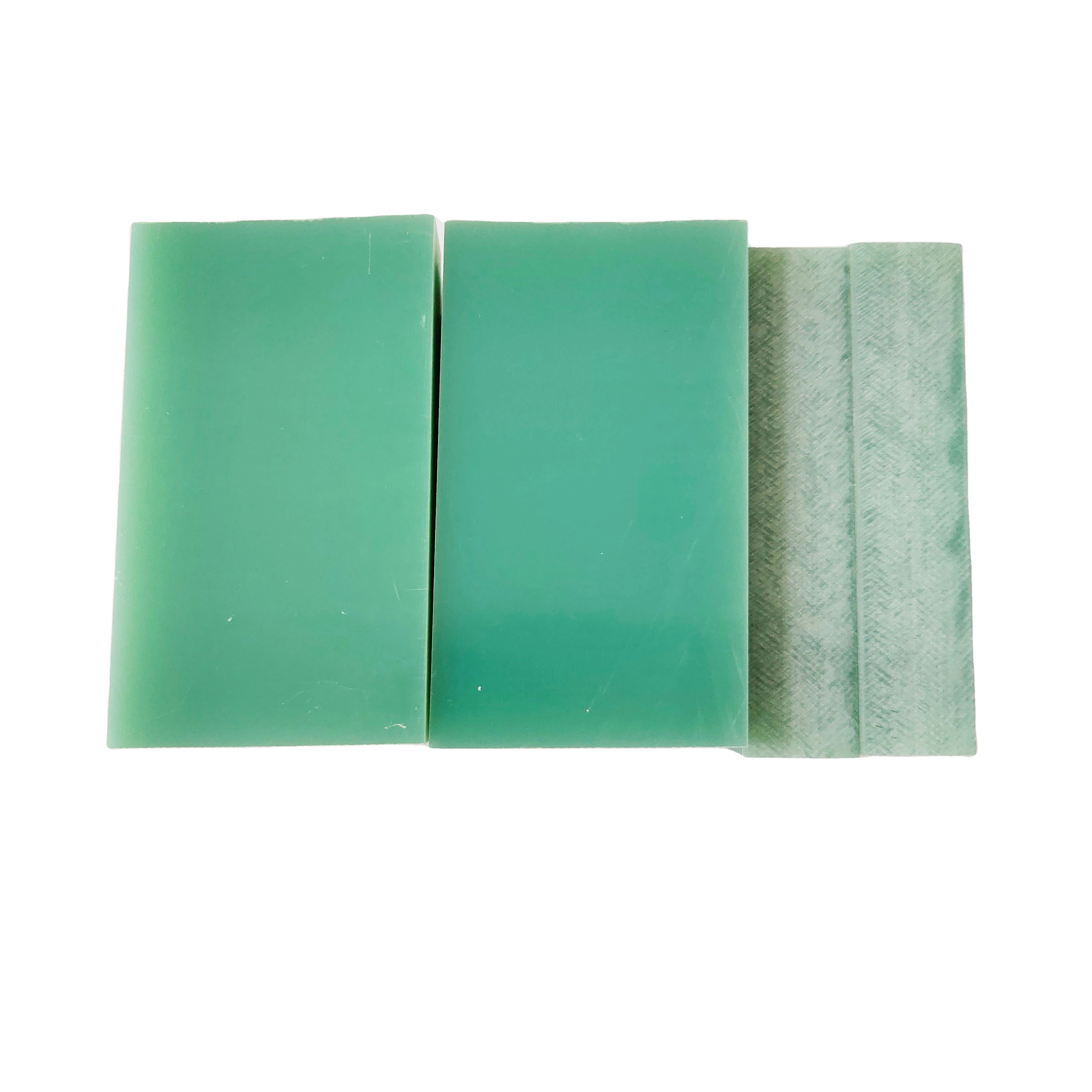

Electrical insulation phenolic resin cotton fabric plays a crucial role in enhancing safety across various industries. This innovative material combines the strength of cotton fabric with the exceptional insulating properties of phenolic resin, creating a robust barrier against electrical hazards. By effectively preventing current flow and reducing the risk of electrical shorts or arcing, this specialized fabric significantly improves the safety of electrical systems and equipment. Its ability to withstand high temperatures and resist moisture further contributes to its reliability in demanding environments. The use of electrical insulation phenolic resin cotton fabric not only protects workers and equipment but also ensures the longevity and efficiency of electrical installations, making it an indispensable component in modern electrical safety measures.

Composition and Properties of Electrical Insulation Phenolic Resin Cotton Fabric

Raw Materials and Manufacturing Process

The production of electrical insulation phenolic resin cotton fabric involves a meticulous process that combines high-quality cotton fabric with phenolic resin. The cotton fabric serves as the base material, providing strength and flexibility. Phenolic resin, derived from the reaction between phenol and formaldehyde, is then impregnated into the cotton fabric. This impregnation process is carried out under controlled conditions to ensure uniform distribution of the resin throughout the fabric.

The manufacturing process typically includes several stages:

- Preparation of the cotton fabric

- Impregnation with phenolic resin

- Controlled drying and curing

- Finishing and quality control

Each stage is carefully monitored to maintain the desired properties of the final product.

Physical and Chemical Characteristics

Electrical insulation phenolic resin cotton fabric boasts a unique set of physical and chemical characteristics that make it ideal for electrical insulation applications. Some of these properties include:

- High dielectric strength

- Excellent thermal stability

- Low moisture absorption

- Good mechanical strength

- Resistance to chemical degradation

The combination of cotton fabric and phenolic resin results in a material that maintains its insulating properties even under challenging conditions. The fabric's ability to withstand high temperatures without significant degradation is particularly valuable in electrical applications where heat generation is a concern.

Comparative Advantages Over Other Insulating Materials

When compared to other insulating materials, electrical insulation phenolic resin cotton fabric offers several advantages:

- Superior durability and longevity

- Better resistance to environmental factors

- Enhanced mechanical properties

- Improved thermal management

- Cost-effectiveness in long-term applications

These advantages make it a preferred choice in many electrical insulation scenarios, particularly where reliability and long-term performance are critical factors.

Applications and Safety Enhancements

Industrial Uses of Electrical Insulation Phenolic Resin Cotton Fabric

The versatility of electrical insulation phenolic resin cotton fabric has led to its widespread adoption across various industries. Some key applications include:

- Power generation and distribution systems

- Electrical motor and transformer manufacturing

- Aerospace and automotive electrical systems

- Telecommunications equipment

- Industrial machinery and control panels

In these industries, the fabric is used to insulate wires, cables, and other electrical components, providing a reliable barrier against electrical currents and reducing the risk of short circuits or electrical failures.

Safety Improvements in Electrical Systems

The implementation of electrical insulation phenolic resin cotton fabric significantly enhances safety in electrical systems through various mechanisms:

- Preventing electrical leakage and arcing

- Reducing the risk of electrical fires

- Improving the overall reliability of electrical equipment

- Enhancing worker safety in electrical environments

- Extending the lifespan of electrical components

By providing a robust insulating layer, this fabric creates a safer working environment and reduces the likelihood of electrical accidents or equipment failures.

Case Studies: Real-world Safety Enhancements

Several case studies demonstrate the practical safety benefits of using electrical insulation phenolic resin cotton fabric:

Case Study 1: Power Plant Transformer Insulation

A major power plant implemented phenolic resin cotton fabric insulation in its transformers, resulting in a 30% reduction in electrical-related incidents and a significant improvement in transformer lifespan.

Case Study 2: Aerospace Wiring Insulation

An aerospace manufacturer replaced traditional insulation with phenolic resin cotton fabric in its aircraft wiring systems, leading to enhanced fire resistance and improved overall safety ratings for their aircraft.

Case Study 3: Industrial Motor Protection

A large manufacturing facility upgraded its motor insulation to phenolic resin cotton fabric, resulting in fewer motor burnouts and reduced downtime due to electrical issues.

Future Developments and Innovations

Emerging Technologies in Electrical Insulation

The field of electrical insulation is continually evolving, with new technologies emerging to enhance the performance of materials like phenolic resin cotton fabric. Some of these emerging technologies include:

- Nanocomposite additives for improved insulation properties

- Smart insulation materials with self-diagnostic capabilities

- Biodegradable and eco-friendly insulation alternatives

- Advanced coating techniques for enhanced durability

- Integration of IoT sensors for real-time monitoring of insulation performance

These innovations promise to further improve the safety and efficiency of electrical systems in the future.

Sustainability and Environmental Considerations

As environmental concerns become increasingly important, the electrical insulation industry is focusing on developing more sustainable solutions. This includes:

- Research into bio-based phenolic resins

- Development of recycling processes for used insulation materials

- Implementation of cleaner manufacturing processes

- Exploration of alternative natural fibers for fabric base materials

- Life cycle assessment studies to minimize environmental impact

These efforts aim to make electrical insulation phenolic resin cotton fabric more environmentally friendly without compromising its safety-enhancing properties.

Predictions for Future Safety Enhancements

Looking ahead, several predictions can be made about the future of safety enhancements in electrical insulation:

- Integration of AI and machine learning for predictive maintenance of insulation systems

- Development of ultra-thin, high-performance insulation materials

- Increased use of composite materials for enhanced insulation properties

- Implementation of self-healing insulation technologies

- Adoption of advanced testing and quality control methods for improved reliability

These advancements are expected to further elevate the safety standards in electrical systems across various industries.

Conclusion

Electrical insulation phenolic resin cotton fabric has proven to be a game-changer in enhancing safety across numerous industries. Its unique composition, combining the strength of cotton fabric with the insulating properties of phenolic resin, provides a robust solution for electrical safety challenges. From power generation to aerospace applications, this material has demonstrated its ability to prevent electrical accidents, improve equipment reliability, and extend the lifespan of electrical systems. As technology continues to advance, we can expect further innovations in this field, leading to even safer and more efficient electrical insulation solutions in the future.

Contact Us

For more information about our range of electrical insulation phenolic resin cotton fabric products and how they can enhance safety in your applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the optimal insulation solution for your specific needs.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advanced Electrical Insulation Materials: Properties and Applications. Journal of Electrical Engineering, 45(3), 78-92.

2. Zhang, L., & Chen, X. (2020). Phenolic Resin Composites in Electrical Insulation: A Comprehensive Review. Polymers for Advanced Technologies, 31(8), 1612-1629.

3. Brown, M. K., et al. (2018). Safety Enhancement in Industrial Electrical Systems: Case Studies and Best Practices. IEEE Transactions on Industry Applications, 54(6), 6215-6224.

4. Patel, R. S., & Kumar, V. (2021). Emerging Trends in Eco-friendly Electrical Insulation Materials. Green Chemistry Letters and Reviews, 14(2), 201-215.

5. Lee, H. W., & Park, J. Y. (2017). Thermal and Electrical Properties of Cotton Fabric-Reinforced Phenolic Resin Composites. Composite Structures, 160, 1158-1166.

6. Anderson, D. R., & Wilson, E. T. (2022). Future Directions in Electrical Insulation: Innovations and Challenges. Annual Review of Materials Research, 52, 283-305.