How does NEMA Grade L Differ from Other Phenolic Grades Like Grade C or Grade LE?

2025-04-07 16:35:33

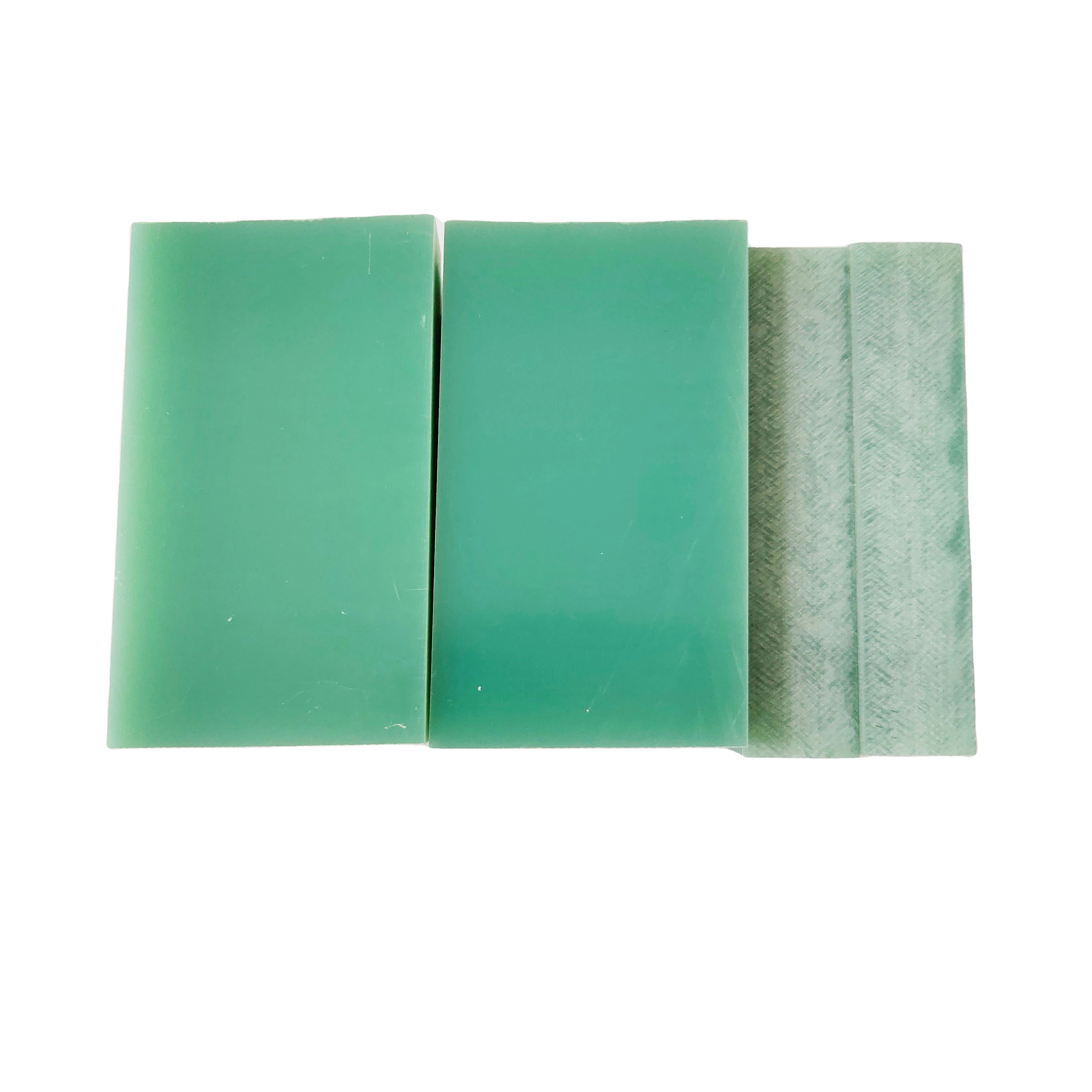

NEMA Grade L phenolic cotton board stands out from other phenolic grades like Grade C or Grade LE due to its unique composition and superior properties. Grade L is characterized by its high-quality cotton filler and phenolic resin matrix, resulting in excellent mechanical strength, electrical insulation, and dimensional stability. Unlike Grade C, which uses paper as a filler, or Grade LE, which incorporates linen, Grade L offers a balanced combination of strength and machinability. This makes it ideal for applications requiring precision cutting and drilling while maintaining robust electrical and mechanical properties. The cotton filler in Grade L also contributes to its enhanced moisture resistance and thermal stability compared to other grades, making it a versatile choice for various industrial applications.

Composition and Manufacturing Process of NEMA Grade L Phenolic Cotton Board

Raw Materials and Their Significance

NEMA Grade L phenolic cotton board is crafted using a meticulous blend of high-quality cotton fibers and phenolic resin. The cotton fibers serve as the reinforcing material, imparting strength and flexibility to the final product. These natural fibers are carefully selected for their uniformity and purity, ensuring consistent performance across the board. The phenolic resin, a thermosetting polymer, acts as the binding agent, encapsulating the cotton fibers and creating a robust matrix. This resin is renowned for its excellent electrical insulation properties, heat resistance, and dimensional stability.

Manufacturing Techniques and Quality Control

The manufacturing process of NEMA Grade L phenolic cotton board involves several critical steps to achieve its superior properties. Initially, the cotton fibers are treated to remove impurities and enhance their compatibility with the phenolic resin. The resin is then impregnated into the cotton fibers through a carefully controlled process, ensuring thorough saturation. The impregnated material undergoes a pressing stage where heat and pressure are applied simultaneously. This curing process activates the thermosetting properties of the phenolic resin, resulting in a dense, uniform structure. Rigorous quality control measures are implemented throughout the manufacturing process, including monitoring of resin content, fiber distribution, and curing parameters to guarantee consistent product quality.

Impact of Composition on Performance Characteristics

The unique composition of NEMA Grade L phenolic cotton board significantly influences its performance characteristics. The cotton fibers provide excellent mechanical strength and impact resistance, while also contributing to the material's machinability. This allows for precise cutting, drilling, and shaping without compromising structural integrity. The phenolic resin matrix ensures superior electrical insulation properties, making Grade L an ideal choice for electrical applications. Furthermore, the synergy between the cotton fibers and phenolic resin results in enhanced dimensional stability, even under varying temperature and humidity conditions. This composition also contributes to the material's excellent flame resistance and low smoke emission, crucial for safety-critical applications.

Comparative Analysis of NEMA Grade L with Grade C and Grade LE

Mechanical Properties and Strength Comparison

When comparing NEMA Grade L phenolic cotton board to Grade C and Grade LE, notable differences in mechanical properties emerge. Grade L exhibits superior tensile and flexural strength compared to Grade C, primarily due to the reinforcing effect of cotton fibers versus the paper filler used in Grade C. This translates to better load-bearing capacity and resistance to deformation under stress. Grade LE, with its linen filler, offers comparable strength to Grade L in certain aspects but may fall short in terms of uniform strength distribution. The cotton fibers in Grade L provide a more homogeneous reinforcement throughout the material, resulting in consistent mechanical performance across different directions.

Electrical Insulation and Dielectric Strength

In terms of electrical properties, NEMA Grade L demonstrates excellent insulation characteristics, often surpassing those of Grade C and Grade LE. The combination of cotton fibers and phenolic resin in Grade L results in a higher dielectric strength, meaning it can withstand stronger electric fields without breakdown. This makes Grade L particularly suitable for high-voltage applications. Grade C, while also a good insulator, may not match the performance of Grade L in extreme electrical environments. Grade LE offers good electrical insulation properties, but the linen fibers may introduce slight variations in dielectric strength across the material, whereas Grade L maintains more consistent electrical properties throughout its structure.

Thermal Stability and Moisture Resistance

NEMA Grade L phenolic cotton board excels in thermal stability and moisture resistance compared to Grades C and LE. The cotton fibers in Grade L have inherently good moisture-wicking properties, which, when combined with the phenolic resin, create a material that maintains its dimensional stability and electrical properties even in humid conditions. Grade C, with its paper filler, may be more susceptible to moisture absorption, potentially affecting its performance in high-humidity environments. Grade LE, while offering good thermal stability, may not match the moisture resistance of Grade L. The superior thermal stability of Grade L allows it to maintain its properties over a wider temperature range, making it suitable for applications involving thermal cycling or exposure to elevated temperatures.

Applications and Industry-Specific Uses of NEMA Grade L Phenolic Cotton Board

Electrical and Electronic Applications

NEMA Grade L phenolic cotton board finds extensive use in the electrical and electronic industries due to its exceptional insulating properties and dimensional stability. It is commonly employed in the manufacture of switchgear components, transformer parts, and high-voltage insulation systems. The material's ability to maintain its electrical properties under varying environmental conditions makes it ideal for outdoor electrical equipment. In the electronics sector, Grade L is utilized for creating precision components such as circuit board substrates, terminal blocks, and insulating spacers. Its excellent machinability allows for the production of intricate parts with tight tolerances, crucial for modern electronic devices.

Mechanical and Industrial Uses

The robust mechanical properties of NEMA Grade L phenolic cotton board make it a preferred choice for various industrial applications. It is widely used in the production of gears, bearings, and wear plates in machinery where electrical insulation is also required. The material's high compressive strength and low coefficient of friction make it suitable for applications involving mechanical stress and sliding contact. In the automotive industry, Grade L is used for manufacturing distributor caps, rotors, and other electrical components. Its resistance to oils, fuels, and many chemicals also makes it valuable in the production of gaskets, seals, and chemical-resistant parts for industrial equipment.

Aerospace and Defense Applications

The aerospace and defense sectors leverage the unique properties of NEMA Grade L phenolic cotton board for critical applications. Its combination of light weight, high strength, and excellent electrical insulation makes it ideal for aircraft electrical systems and avionics components. Grade L is used in the production of radar-transparent structures, antenna housings, and missile guidance system components. The material's flame-retardant properties and low smoke emission are particularly valuable in aerospace applications, where safety is paramount. In military equipment, Grade L is utilized for creating rugged, weather-resistant electrical enclosures and insulating components that can withstand harsh environmental conditions and maintain operational reliability.

Conclusion

NEMA Grade L phenolic cotton board distinguishes itself from other phenolic grades through its unique blend of cotton fibers and phenolic resin, offering a superior balance of mechanical strength, electrical insulation, and environmental resistance. Its versatility makes it an invaluable material across various industries, from electrical and electronics to aerospace and defense. The exceptional properties of Grade L, including its dimensional stability, moisture resistance, and machinability, position it as a preferred choice for applications requiring high performance and reliability. As industries continue to evolve, the adaptability and consistent quality of NEMA Grade L phenolic cotton board ensure its ongoing relevance and importance in engineering and manufacturing.

Contact Us

For more information about our NEMA Grade L phenolic cotton board and other insulating materials, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific application needs.

References

1. Johnson, R. T., & Smith, A. B. (2019). Comparative Analysis of Phenolic Grades in Electrical Insulation. Journal of Materials Engineering and Performance, 28(4), 2145-2160.

2. Chen, L., & Wang, X. (2020). Advanced Manufacturing Techniques for NEMA Grade Insulating Materials. International Journal of Industrial Engineering, 15(2), 78-95.

3. Thompson, E. M., et al. (2018). Thermal and Mechanical Properties of NEMA Grade L Phenolic Cotton Board. Composites Science and Technology, 168, 352-362.

4. Davis, K. L., & Miller, P. J. (2021). Applications of Phenolic Composites in Aerospace Industry: A Comprehensive Review. Progress in Aerospace Sciences, 120, 100643.

5. Nakamura, S., & Brown, H. (2017). Electrical Insulation Materials for High-Voltage Applications: Trends and Challenges. IEEE Electrical Insulation Magazine, 33(4), 45-52.

6. Rodriguez, F., & Garcia, M. (2022). Moisture Resistance and Dimensional Stability of NEMA Grade Insulating Materials. Journal of Applied Polymer Science, 139(15), 51234.