How does a Flame Resistance FR4 Fiber Glass Laminate Sheet compare to traditional FR4 sheets?

2024-05-15 14:32:33

Introduction to FR4 Materials

Flame Resistance FR4 Fiber Glass Laminate Sheet, standing for Flame Retardant 4, is a widely recognized material in electronics and other industrial applications due to its balance of mechanical strength, electrical insulation, and flame retardant properties. It is a composite made from woven fiberglass cloth and an epoxy resin binder, which contributes to its robustness and performance in demanding environments (Wikipedia) (FR4 Board) (Atlas Fibre).FR4 sheets, whether flame resistant or traditional, share fundamental characteristics owing to their composition and purpose. However, the key difference lies in the flame resistance properties.

FR4 materials are ubiquitous in electronics and electrical engineering due to their exceptional properties, including:

Electrical Insulation: FR4 offers high electrical insulation properties, crucial for preventing electrical shorts and ensuring the integrity of electronic circuits.

Mechanical Strength: The fiberglass reinforcement provides FR4 with excellent mechanical strength, making it resistant to bending, flexing, and impact, ideal for structural support in electronic assemblies.

Dimensional Stability: FR4 maintains its dimensional stability over a wide range of temperatures and environmental conditions, ensuring consistent performance in various applications.

Chemical Resistance: FR4 exhibits resistance to many chemicals, making it suitable for use in environments where exposure to solvents, oils, and other chemicals is possible.

Cost-Effectiveness: FR4 materials are relatively cost-effective compared to alternative materials with similar properties, making them a preferred choice in many applications.

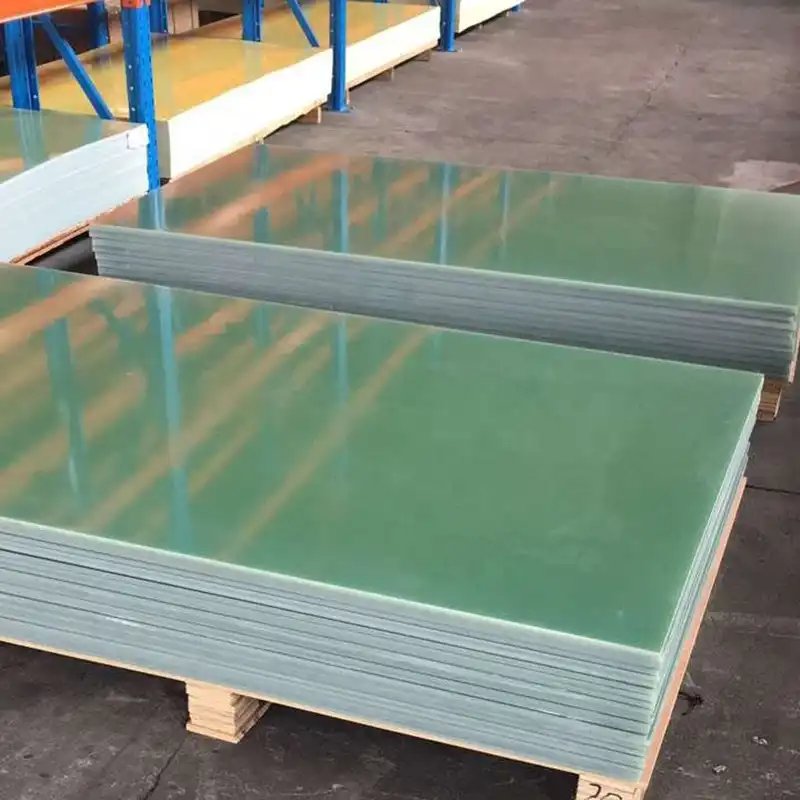

Material Composition and Properties

Traditional FR4 sheets are known for their excellent mechanical and electrical insulation properties. These sheets consist of a woven fiberglass and a flame-retardant epoxy resin, making them ideal for uses in environments that require high durability and resistance to electrical disturbances. The material's flame retardance, indicated by the 'FR' in FR4, is a critical factor, especially in applications that involve potential fire hazards (FR4 Board) (FR4 Material).

Fiberglass Cloth:FR4 starts with a woven fiberglass cloth, typically made from thin strands of glass fibers. This fiberglass cloth provides the material with strength, rigidity, and dimensional stability.

Epoxy Resin Binder:The fiberglass cloth is impregnated with an epoxy resin binder. Epoxy resins are thermosetting polymers that provide adhesion, mechanical strength, and chemical resistance to the composite material.

Flame Retardant Additives:FR4 formulations incorporate flame retardant additives to enhance the material's fire resistance. These additives, such as brominated compounds or phosphorous compounds, inhibit the spread of flames and reduce smoke generation during combustion.

Other Additives (Optional):Depending on specific formulations and requirements, FR4 may contain additional additives such as fillers, reinforcements, antioxidants, or pigments to modify its properties or enhance performance in certain applications.

Enhancements in Flame Resistance

While traditional FR4 sheets already possess flame retardant properties, advancements in material technology have led to the development of FR4 sheets with enhanced flame resistance. These are specifically designed to meet higher safety standards required in certain high-risk industries such as aerospace and automotive manufacturing. The enhanced Flame Resistance FR4 Fiber Glass Laminate Sheet not only adhere to the basic properties of standard FR4 but also offer improved performance in fire safety tests (FR4 Board).

Flame Retardant Additives:Incorporating flame retardant additives into the FR4 formulation is one of the most common methods to enhance flame resistance. These additives can include halogenated compounds (e.g., brominated flame retardants), phosphorous compounds, or other chemical agents that disrupt the combustion process and inhibit flame spread.

Intumescent Coatings:Intumescent coatings can be applied to FR4 surfaces to improve flame resistance. When exposed to heat, these coatings swell and form a protective char layer that insulates the material and slows down the spread of flames.

Nanostructured Materials:Nanostructured materials, such as nanoparticles or nanoclays, can be incorporated into FR4 formulations to enhance flame resistance. These materials can improve the material's thermal stability and form a barrier against heat and flame propagation.

Synergistic Flame Retardant Systems:Combining multiple flame retardant additives or techniques into a synergistic system can enhance the overall flame resistance of FR4 materials. By leveraging the complementary effects of different additives, synergistic systems can achieve better fire safety performance than individual components alone.

Phosphorus-based Flame Retardants:Phosphorus-based flame retardants are effective additives for improving the flame resistance of FR4 materials. They can act through various mechanisms, such as charring, gas-phase suppression, or radical scavenging, to inhibit flame propagation and reduce smoke generation.

Performance Under Extreme Conditions

Enhanced FR4 sheets are particularly valued in environments that are exposed to extreme conditions. This includes higher temperatures or harsh chemical exposures where traditional FR4 might not suffice.

The improved sheets maintain their structural integrity and performance characteristics even under such extreme conditions, thereby extending their usability and reliability (Wikipedia) (Atlas Fibre).

Applications and Usability

The choice between traditional FR4 and enhanced flame-resistant FR4 often depends on the specific requirements of the project or application.

Traditional FR4 is suitable for general electronic applications like printed circuit boards used in consumer electronics and other devices, while the enhanced FR4 is preferred in sectors requiring higher safety measures against fire hazards (beeplastic) (FR4 Material).

Selecting the Right Material for Your Needs

When choosing between traditional and enhanced FR4 sheets, it is essential to consider the specific needs of your application, including environmental conditions and safety requirements.

Understanding the distinct properties of each type can guide you in making an informed decision that ensures both performance and compliance with industry standards (beeplastic) (Atlas Fibre).

Conclusion

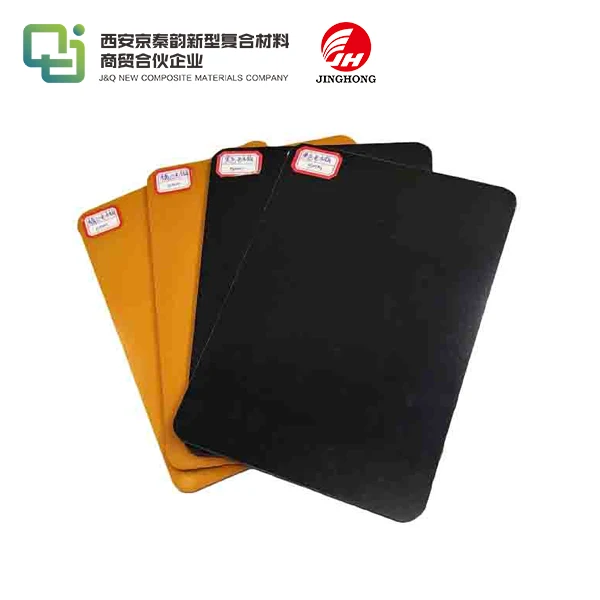

As a professional manufacturer and supplier, we provide both traditional and enhanced Flame Resistance FR4 Fiber Glass Laminate Sheet, manufactured in GMP-certified facilities with large stock availability and complete certifications. Our products support customization (OEM), fast delivery, secure packaging, and testing services. We welcome you to contact us to discuss how our FR4 solutions can meet your specific needs, ensuring high performance and safety in your projects.

This overview provides a fundamental understanding of how enhanced FR4 fiber glass laminate sheets compare to traditional FR4 sheets. For detailed specifications or to explore our range of products, feel free to reach out to our team.