How do you install or use Epoxy Fiberglass Tubes in construction projects?

2024-08-22 14:33:40

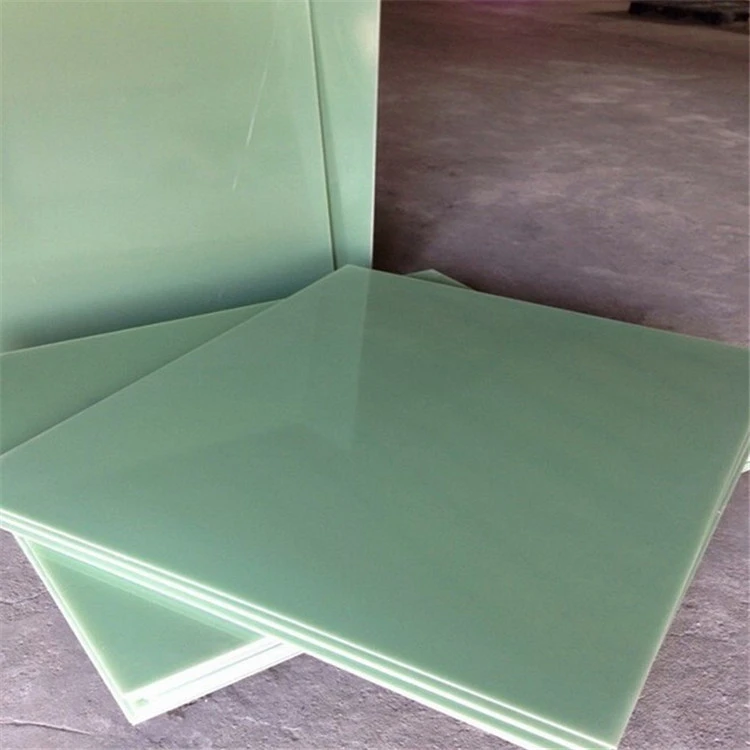

When it comes to construction projects, selecting the right materials is key to ensuring longevity and structural integrity. Epoxy fiberglass tubes, known for their durability, insulation properties, and resistance to environmental factors, have become a staple in many construction applications. This blog will guide you through the process of installing and using epoxy fiberglass tubes effectively in your construction projects.

Why Choose Epoxy Fiberglass Tubes for Construction?

Epoxy fiberglass tubes are favored in construction for their exceptional strength-to-weight ratio, electrical insulation capabilities, and resistance to corrosion and chemicals. These properties make them ideal for a wide range of construction applications, from supporting structures to electrical conduits. But what specific advantages do they offer in construction?

Understanding the Structural Benefits of Epoxy Fiberglass Tubes

- Lightweight Yet Strong: Epoxy fiberglass tubes are significantly lighter than metals like steel or aluminum, yet they offer comparable strength. This makes them easier to handle and reduces the overall weight of the structure, which can be crucial in projects where load management is important.

- Resistant to Corrosion: Unlike metal pipes that can rust over time, epoxy fiberglass tubes are highly resistant to corrosion, making them ideal for use in environments where they may be exposed to moisture or chemicals.

- Thermal and Electrical Insulation: These tubes provide excellent thermal and electrical insulation, making them a safe choice for projects that require materials to withstand high temperatures or to insulate electrical components.

Common Applications of Epoxy Fiberglass Tubes in Construction

- Structural Supports and Beams: Due to their strength and lightweight nature, epoxy fiberglass tubes are often used as structural supports in buildings and bridges. They provide the necessary strength without adding excessive weight to the structure.

- Electrical Conduits and Cable Management: The tubes are frequently used to encase electrical wiring, providing both physical protection and electrical insulation, reducing the risk of electrical hazards.

- Reinforcement in Composite Structures: In many modern construction projects, epoxy fiberglass tubes are used to reinforce composite materials, enhancing the strength and durability of the finished structure.

Choosing the Right Epoxy Fiberglass Tubes for Your Project

- Assessing Load Requirements: Before selecting epoxy fiberglass tubes, it’s important to assess the load they will need to bear. This will determine the diameter and wall thickness required for the tubes.

- Environmental Considerations: Consider the environmental conditions the tubes will be exposed to. For instance, if they will be in a corrosive or high-temperature environment, you may need tubes with specific coatings or treatments.

- Compliance with Standards: Ensure that the epoxy fiberglass tubes you choose comply with relevant construction standards and regulations, particularly in relation to fire safety, electrical insulation, and load-bearing capacities.

Step-by-Step Guide to Installing Epoxy Fiberglass Tubes

Installing epoxy fiberglass tubes requires careful planning and execution to ensure they function optimally within the structure. Here’s a detailed guide to help you through the process.

Preparation and Planning

- Design and Blueprint Alignment: Before installation, ensure that your design plans incorporate the correct placement and dimensions of the epoxy fiberglass tubes. Misalignment can lead to structural weaknesses or the need for costly adjustments.

- Site Preparation: Clear the installation site of any debris or obstacles that might interfere with the placement of the tubes. A clean and well-prepared site ensures a smoother installation process.

- Tool and Material Check: Gather all necessary tools and materials before starting the installation. This includes cutting tools, fastening materials, and safety equipment. Double-check that the epoxy fiberglass tubes are free from any damage or defects.

Installation Process

- Cutting to Size: Depending on your specific needs, you may need to cut the tubes to the desired length. Use a fine-tooth saw or a specialized cutting tool to ensure clean cuts without splintering the fiberglass.

- Securing in Place: Position the tubes according to your design plans and secure them using appropriate fasteners. In some cases, you may need to drill holes for bolts or screws, making sure not to compromise the structural integrity of the tubes.

- Sealing and Insulation: If the tubes are used for electrical purposes, ensure all connections are properly insulated to prevent electrical hazards. Apply sealant where necessary to protect the tubes from moisture or chemical exposure.

Final Inspection and Testing

- Structural Integrity Check: After installation, conduct a thorough inspection to ensure the tubes are securely fastened and aligned correctly. Check for any signs of damage that might have occurred during installation.

- Functional Testing: If the tubes are part of an electrical system, test the insulation and continuity to ensure there are no faults. For structural applications, load testing may be required to confirm that the tubes can bear the intended weight.

- Compliance Verification: Finally, verify that the installation meets all relevant building codes and safety standards. This is crucial for both legal compliance and the safety of the structure.

Best Practices for Using Epoxy Fiberglass Tubes in Construction

To maximize the benefits of epoxy fiberglass tubes in your construction projects, it’s important to follow best practices for their use. These practices ensure longevity, safety, and efficiency in the application of these materials.

Regular Maintenance and Inspection

- Scheduled Inspections: Periodically inspect the epoxy fiberglass tubes for signs of wear, damage, or environmental degradation. Regular maintenance can extend the life of the tubes and prevent failures.

- Cleaning and Care: Keep the tubes clean, especially in environments where they might be exposed to chemicals or corrosive agents. Use appropriate cleaning agents that won’t damage the epoxy or fiberglass material.

- Repair and Replacement: If you find any damaged tubes, replace them promptly to avoid compromising the structural integrity of the entire system. Use the same type and quality of epoxy fiberglass tubes for replacements to maintain consistency.

Adapting to Changing Environmental Conditions

- Weather Resistance: If the construction site is exposed to harsh weather conditions, consider additional protective measures such as coatings or shields to protect the tubes.

- Temperature Fluctuations: Be mindful of how temperature changes can affect the performance of epoxy fiberglass tubes. In environments with extreme temperature variations, choose tubes with enhanced thermal resistance.

- Chemical Exposure: In industrial or chemical-heavy environments, ensure that the tubes have adequate resistance to the specific chemicals they might encounter. This may involve selecting tubes with specialized coatings or finishes.

Optimizing for Specific Applications

- Customization Options: Take advantage of the customization options available with epoxy fiberglass tubes. These can include varying diameters, wall thicknesses, and lengths to fit specific project requirements.

- Integration with Other Materials: When using epoxy fiberglass tubes in conjunction with other materials, ensure they are compatible and won’t cause issues like galvanic corrosion or material degradation.

- Energy Efficiency Considerations: For projects focusing on energy efficiency, use epoxy fiberglass tubes that contribute to reducing heat loss or insulating electrical components, thus enhancing the overall energy performance of the building.

Contact Us

With over 20 years of experience in producing and selling insulating materials and more than a decade in foreign trade, J&Q is your trusted partner for high-quality epoxy fiberglass tubes. Whether you're working on a small project or a large-scale construction, our products are designed to meet your needs with precision and reliability. For more information or to discuss your specific requirements, feel free to contact us at info@jhd-material.com. Let us help you achieve excellence in your construction projects with our superior epoxy fiberglass tubes.

References

1. "Fiberglass Reinforced Epoxy Tubes: Structural Applications and Benefits." Journal of Composite Materials, 2020.

2. "Corrosion Resistance of Epoxy-Fiberglass Composites in Construction." Materials Science and Engineering, 2019.

3. "The Role of Epoxy Fiberglass Tubes in Modern Construction." Construction Materials Review, 2021.

4. "Electrical Insulation Properties of Fiberglass Reinforced Epoxy Tubes." Electrical Engineering Journal, 2020.

5. "Thermal Performance of Epoxy Fiberglass Tubes in High-Temperature Applications." Journal of Thermal Engineering, 2019.

6. "Load-Bearing Capabilities of Fiberglass Epoxy Tubes in Structural Applications." Civil Engineering Materials, 2021.