Guide of Development of Electric Resistant Epoxy Sheet

2022-09-08

1. Foreword

3240 epoxy sheet is widely used as insulation material in electromechanical equipment because of its high mechanical and electrical properties, low water absorption, light color, beautiful and clean. However, with the development of the motor industry, higher requirements are put forward for the ability of insulation materials to adapt to harsh environments, and the harm of leakage traces is becoming more and more obvious. Therefore, it is of great practical significance to develop an epoxy board with resistance to electric traces.

According to the current situation of domestic F-grade epoxy board, bisphenol A epoxy blade DS curing system is mostly used. On this basis, it is understood that alicyclic epoxy resin has good high-temperature electrical properties and electric trace resistance index, and is very different from bisphenol A epoxy resin in chemical structure and performance. Its chemical structure determines that the reaction activity is lower than that of bisphenol A epoxy resin. When reacting with amines, the reaction speed of alicyclic epoxides is much slower. Therefore, it is prepared to replace part of bisphenol A-type epoxy with alicyclic epoxy, and adjust it on the basis of the existing process, adding accelerants to adjust the gelation time of the resin.

2. Experiment

a) Synthesis of electric trace resistant epoxy resin

i. Material

E-44 epoxy resin, industrial product; Alicyclic epoxy resin, industrial products; 4.4-diaminodiphenyl benzene, industrial product; Toluene / alcohol mixed solvent, industrial product; Accelerator, reagent.

ii. Formula Selection

Material ratio (E-44 / alicyclic epoxy resin) | CTI of laminate sheet |

7/1 mass fraction | 300 |

6.5/1 mass fraction | 375 |

6/1 mass fraction | 425 |

5/1 mass fraction | 550 |

≤4.5/1 mass fraction | 600 pass |

iii. Synthetic process

Add E-44 epoxy resin, alicyclic epoxy resin and DDS into the reaction kettle according to the formula, heat up and stir. After reacting at a certain temperature for a certain time, add polyphenylene, adjust the gelation time with a promoter to meet the specified value of technical requirements, add toluene alcohol mixed solvent, cool, filter and package to obtain an electric trace resistant epoxy resin solution.

iv. Resin properties

See Table 1 for the general performance indexes of the electric trace resistant epoxy resin solution

Resin solution properties

Project | Index |

Appearance | Yellow transparent liquid |

Viscosity, s | 20~40 |

Solids content, % | 60~70 |

Forming time, min | 5~10 |

The storage period of the electric trace resistant epoxy resin at room temperature is 7 days at room temperature. If it exceeds the storage period, it can still be used if the gelation time is within the range.

b) Preparation of epoxy glass cloth prepreg with resistance to electric trace

The alkali free glass cloth treated with the coupling agent is impregnated with the electric trace resistant epoxy resin solution, and the prepreg is prepared on the double effect vertical sizing machine according to the following process conditions: vehicle speed: 1.0m/s ~ 5.0m/s; Tower temperature: 100 ℃ ~ 160 ℃.

See Table 2 for performance indexes of prepreg

Properties of prepreg

Project | Index |

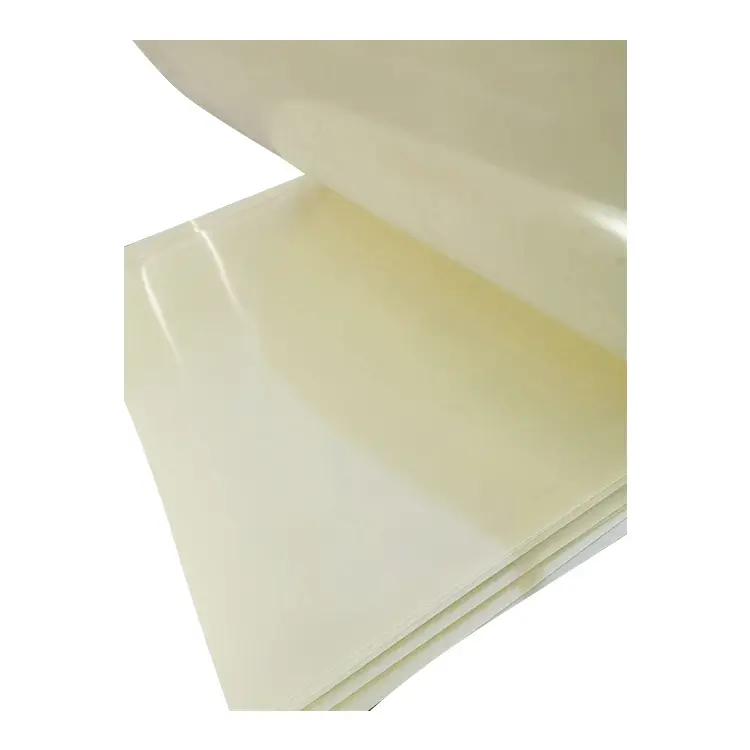

Appearance | canary yellow |

Resin content % | 40±5 |

Soluble resin content % | ≥90 |

Volatile content % | ≤2 |

c) Preparation of glass cloth laminate

Cut the prepreg to the required size, lay it according to the process requirements, pad both sides with polished stainless steel plates, use the patented release agent or film of our company to demould, pad paper and iron plate, and then send it to the preheated press. See Table 3 for the pressing process conditions

Laminate pressing process

Preheat | Hot pressing | ||||

Temperature ℃ | Pressure MPa | Time Min | Temperature ℃ | Pressure MPa | Time Min |

100~150 | 1~8 | 30~90 | 180±5 | 8 | 120 |

After being pressed and molded according to the above process and cooled to below 50 ℃, the Epoxy Glass Sheet can be obtained.

3. Result and discussion

a) Heat resistance of electric trace resistant epoxy glass cloth laminate

Our company uses Netzsch (model: dsc200f3) from Germany to test the Tg of laminate powder by differential scanning calorimetry (DSC). The Tg is 160 ~ 170 ℃, and the temperature index of resin is 177 ℃ calculated according to the rapid thermal aging data. Therefore, this laminate can be used as class F insulation material

b) Mechanical and electrical properties of electric trace resistant epoxy board

The electromechanical properties of the laminate are shown in Table 4. The index values in Table 4 are the technical indexes of epgc306 in iec60893-3-2. It can be seen from this table that the measured values all meet the index requirements.

Mechanical and electrical properties of Epoxy Glass Sheet with resistance to electric traces

Index name | Index value | Measured value | |

Vertical layer bending strength, MPa | Normal Behavior | ≥340 | 556 |

155±2℃ | ≥170 | 289 | |

Parallel layer impact strength (longitudinal, simple support, notch), KJ/m^2 | ≥33 | 52 | |

Vertical layer electric strength (90 ± 2 ℃ in oil), MV/m | 11.8 | 17 | |

Dielectric loss factor (50Hz) | ≤0.04 | 0.021 | |

Dielectric constant (50Hz) | ≤5.5 | 4.8 | |

Insulation resistance after immersion in water, Ω | ≤5.5*10^10 | 3.2*10^13 | |

Compared with the electric trace index, V | 600 | Pass | |

Temperature index, ℃ | ≥155 | 177 | |

Water absorption (2mm sheet), Mg | ≤20 | 12 | |

c) Influence of pressing process on properties of laminates

The performance of Epoxy Laminate Sheet firstly depends on the performance of matrix resin. Under the determined matrix resin and reinforcement materials, temperature, time and pressure are of great importance to the performance of laminates. In combination with the company's equipment and production conditions, a set of pressing process routes for producing high-quality laminates is explored and summarized, which forms process documents and ensures the stability of product quality of various specifications.

4. Conclusion

The electric trace resistant epoxy glass cloth laminate has high mechanical and electrical properties, and has a high index of electric trace resistance. It is suitable for insulation structural parts and mechanical parts in class F motors and electrical equipment. It is also suitable for high temperature, humidity, pollution and other harsh environments. The comprehensive performance index of the laminate meets the technical index of epgc306 in iec60893-3-2. Now it can be mass produced with good economic benefits.

_1732777843529.webp)