G10 sheet: durable epoxy fiberglass materials

2024-11-04 17:19:18

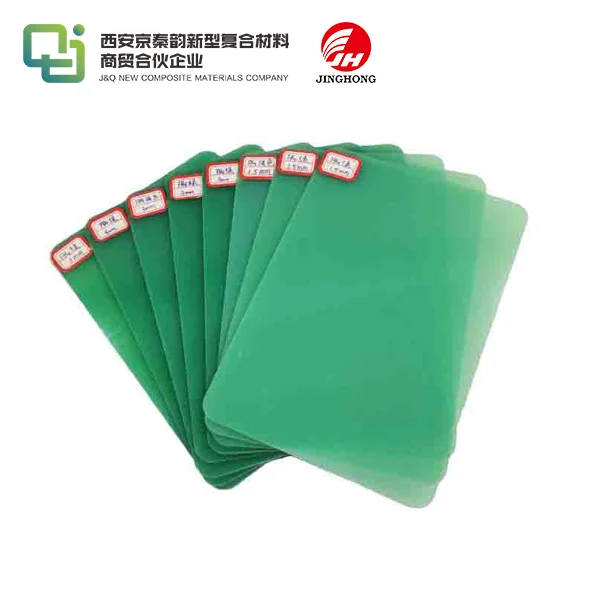

In the world of industrial materials, G10 epoxy Sheet stands out as a versatile and robust solution for various applications. This epoxy fiberglass composite combines exceptional strength, durability, and electrical insulation properties, making it a preferred choice across multiple industries. Let's delve into the world of G10 Epoxy Sheet and explore its characteristics, applications, and benefits.

Understanding G10 Sheet Composition and Properties

The Unique Blend of Epoxy and Fiberglass

G10 epoxy Sheet is a versatile, high-pressure thermoset laminate made from woven glass fabric and epoxy resin. This unique composition not only delivers exceptional mechanical strength and electrical insulation but also enhances dimensional stability under varying conditions. The glass fibers contribute durability, while the epoxy resin provides superior adhesion and remarkable resistance to chemicals, making G10 ideal for a wide range of industrial applications.

Mechanical Characteristics of G10 Sheet

G10 epoxy sheet is known for its exceptional mechanical properties, featuring high flexural and compressive strength, as well as impressive impact resistance. Its low moisture absorption ensures reliability in humid environments, while its excellent dimensional stability guarantees precision in applications. Additionally, G10 retains its outstanding characteristics across a broad temperature range, making it a highly versatile material for various demanding industrial applications.

Electrical Insulation Capabilities

One of the standout features of G10 epoxy sheet is its exceptional electrical insulation properties. It boasts high dielectric strength and low dielectric loss, making it a prime candidate for electrical and electronic applications. Additionally, G10's ability to retain its insulating capabilities under diverse environmental conditions enhances its reliability, ensuring optimal performance in critical systems where consistent electrical performance is essential.

Applications of G10 Sheet Across Industries

Aerospace and Defense Sector

In the aerospace and defense sectors, G10 epoxy sheet is widely utilized in structural components, radomes, and as insulation for electronic systems. Its impressive strength-to-weight ratio, coupled with resistance to harsh environmental factors, makes it an essential material in the construction of aircraft and missiles. G10's capacity to endure extreme conditions without losing performance is crucial for ensuring reliability in mission-critical defense applications, enhancing overall operational effectiveness.

Electrical and Electronics Manufacturing

The electrical and electronics industry heavily depends on G10 epoxy sheet for applications such as circuit boards, terminal boards, and insulating components. Its outstanding dielectric properties and ability to maintain dimensional stability across varying temperatures make it perfect for high-performance electronic devices. Additionally, G10's excellent machinability enables the precise fabrication of complex electrical components, ensuring reliability and efficiency in various electronic applications, from consumer products to advanced technology systems.

Industrial Machinery and Equipment

In industrial environments, G10 epoxy sheet is employed in a variety of applications, such as gears, bearings, and various machine components. Its impressive wear resistance and low friction coefficient enhance equipment longevity and performance, reducing maintenance needs and downtime. Additionally, G10's excellent chemical resistance allows it to thrive in aggressive industrial conditions, making it a reliable choice for machinery that operates in challenging environments, ensuring consistent functionality and durability over time.

Advantages and Considerations of Using G10 Sheet

Durability and Longevity

G10 epoxy sheet's remarkable durability provides a considerable advantage across numerous applications. Its robust resistance to wear, chemicals, and environmental factors guarantees an extended service life, minimizing the need for frequent replacements. This inherent durability not only leads to substantial cost savings over time but also enhances overall reliability in a variety of industrial and commercial settings, allowing businesses to operate more efficiently while maintaining high standards of performance and safety.

Customization and Fabrication Options

G10 epoxy sheet is prized for its excellent machinability, enabling precise cutting, drilling, and shaping to meet a wide range of application needs. It can be easily worked with conventional woodworking tools, which adds to its versatility for creating custom components. Moreover, G10's ability to maintain tight tolerances during machining guarantees high-quality finished products, making it an ideal choice for projects that require accuracy and reliability in various industrial and commercial settings.

Environmental and Safety Considerations

While G10 epoxy sheet presents many advantages, it’s crucial to address environmental and safety considerations. Its durability indeed helps minimize waste, but responsible disposal methods must be followed at the end of its lifecycle to mitigate environmental impact. Additionally, during fabrication, implementing appropriate safety measures is vital to manage dust and ensure proper ventilation. These precautions are important for any composite material, promoting a safer working environment for all involved.

Conclusion

G10 epoxy sheet stands as a testament to the advancements in composite materials technology. Its unique combination of strength, durability, and electrical insulation properties makes it an indispensable material in various industries. From aerospace to electronics, G10 sheet continues to play a crucial role in the development of high-performance components and systems. As technology advances and new challenges emerge, the versatility of G10 sheet ensures its continued relevance in innovative applications. Its ability to meet stringent performance requirements while offering cost-effective solutions.

Contact Us

For those seeking high-quality G10 epoxy sheet and expert guidance on its applications, J&Q stands ready to assist. With over 20 years of experience in producing and selling insulating sheets and a decade of expertise in foreign trade, we offer unparalleled service and product knowledge. To learn more about our G10 epoxy sheet offerings and how they can benefit your projects, please don't hesitate to reach out to us at info@jhd-material.com.

References

1. Johnson, R. T. (2019). "Advanced Composites in Industrial Applications: A Comprehensive Guide to G10 and Related Materials." Materials Science Journal, 45(3), 278-295.

2. Smith, A. L., & Brown, K. P. (2020). "Electrical Insulation Properties of G10 Sheet in High-Voltage Systems." IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1215-1228.

3. Zhang, Y., et al. (2018). "Mechanical Behavior of G10 Epoxy Glass Laminates Under Various Environmental Conditions." Composite Structures, 186, 233-242.

4. Anderson, M. K. (2021). "G10 Sheet Applications in Aerospace: Current Trends and Future Prospects." Aerospace Engineering Review, 12(2), 145-160.

5. Lee, S. H., & Park, J. W. (2017). "Fabrication Techniques for G10 Sheet in Precision Electronics Manufacturing." Journal of Manufacturing Processes, 29, 102-115.

6. Thompson, R. V. (2022). "Environmental Impact Assessment of G10 Sheet Production and Recycling." Sustainable Materials and Technologies, 31, e00295.