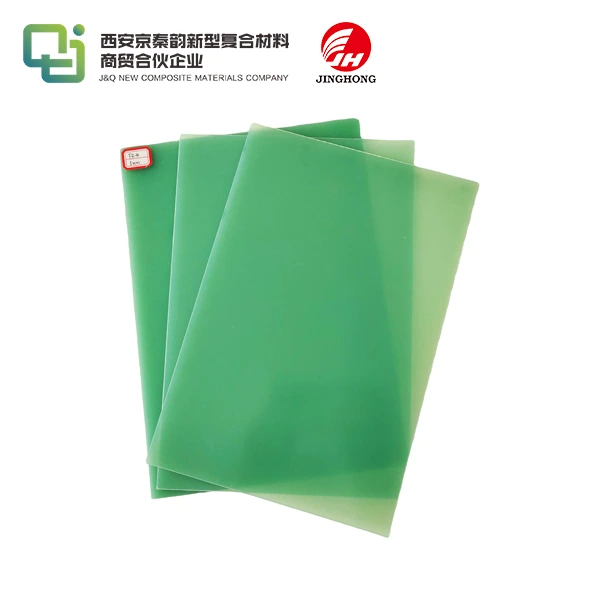

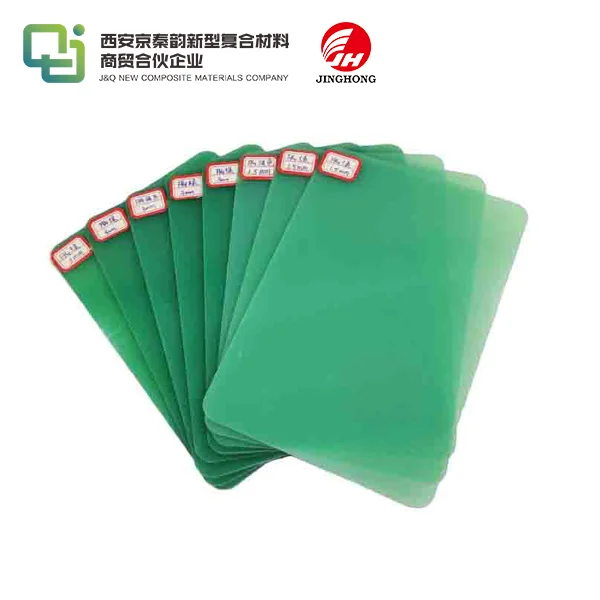

Explore the many advantages of 3240 epoxy sheet

2025-01-13 17:00:36

3240 epoxy sheet is a versatile and robust material that has revolutionized various industries with its exceptional properties. This high-performance laminate combines the strength of epoxy resin with the reinforcement of glass fabric, resulting in a product that excels in electrical insulation, mechanical strength, and thermal stability. From electronics to aerospace applications, 3240 epoxy sheet offers unparalleled advantages in terms of durability, reliability, and performance. Its ability to withstand harsh environments, resist chemical corrosion, and maintain dimensional stability makes it an indispensable component in countless manufacturing processes and end-products. As we delve deeper into the world of 3240 epoxy sheet, we'll uncover the myriad benefits that have made it a preferred choice for engineers and manufacturers across the globe.

Superior Properties of 3240 Epoxy Sheet

Exceptional Electrical Insulation

3240 epoxy sheet boasts remarkable electrical insulation properties, making it an ideal choice for a wide range of applications in the electronics and electrical industries. Its high dielectric strength ensures minimal electrical conductivity, effectively preventing current leakage and short circuits. This characteristic is particularly valuable in the manufacturing of printed circuit boards (PCBs), switchgear components, and other electrical devices where insulation is paramount. The material's low dissipation factor further enhances its performance in high-frequency applications, reducing signal loss and improving overall efficiency.

Outstanding Mechanical Strength

One of the most notable advantages of 3240 epoxy sheet is its exceptional mechanical strength. The combination of epoxy resin and glass fabric reinforcement results in a material that exhibits high tensile strength, compressive strength, and impact resistance. This durability allows 3240 epoxy sheet to withstand significant mechanical stress without deformation or failure, making it suitable for structural applications in industries such as aerospace, automotive, and construction. The material's ability to maintain its mechanical properties under varying temperatures and environmental conditions further enhances its versatility and reliability.

Thermal Stability and Heat Resistance

3240 epoxy sheet demonstrates impressive thermal stability, maintaining its structural integrity and performance across a wide temperature range. This heat-resistant property is crucial in applications where components are exposed to elevated temperatures or thermal cycling. The material's low coefficient of thermal expansion ensures dimensional stability, reducing the risk of warping or distortion in high-temperature environments. This thermal resilience makes 3240 epoxy sheet an excellent choice for applications in the automotive industry, power generation equipment, and industrial machinery where heat management is critical.

Applications and Industries Benefiting from 3240 Epoxy Sheet

Electronics and Electrical Equipment

The electronics industry heavily relies on 3240 epoxy sheet for its superior insulation properties and dimensional stability. In the production of printed circuit boards, the material serves as a reliable substrate, providing a stable foundation for intricate circuit designs. Its excellent electrical characteristics make it ideal for manufacturing various components such as insulators, barriers, and spacers in electrical equipment. The material's ability to withstand high voltages and maintain its properties in challenging environments has made it indispensable in the production of transformers, generators, and switchgear assemblies.

Aerospace and Defense

In the aerospace and defense sectors, 3240 epoxy sheet plays a crucial role in crafting lightweight yet robust components. Its high strength-to-weight ratio makes it an excellent choice for aircraft interiors, structural elements, and radome construction. The material's resistance to moisture absorption and chemical corrosion ensures longevity and reliability in the demanding conditions encountered during flight. Additionally, its flame-retardant properties contribute to enhanced safety measures in aircraft design, meeting stringent industry standards and regulations.

Industrial Machinery and Equipment

The industrial sector benefits greatly from the durability and versatility of 3240 epoxy sheet. Its application extends to the manufacturing of gears, bearings, and other mechanical components that require high wear resistance and low friction. The material's chemical resistance makes it suitable for use in pumps, valves, and seals in chemical processing plants. In the oil and gas industry, 3240 epoxy sheet finds applications in downhole tools and offshore equipment, where its ability to withstand harsh environments and high pressures is invaluable.

Environmental and Economic Advantages of 3240 Epoxy Sheet

Sustainability and Longevity

3240 epoxy sheet contributes to sustainability efforts by offering exceptional durability and longevity. Its resistance to wear, corrosion, and environmental factors significantly extends the lifespan of components and products, reducing the need for frequent replacements. This longevity not only minimizes waste but also decreases the overall environmental impact associated with manufacturing and disposal. Furthermore, the material's stability ensures that it maintains its properties over time, reducing the likelihood of degradation-related failures and the associated environmental risks.

Cost-Effectiveness in the Long Run

While the initial cost of 3240 epoxy sheet may be higher compared to some alternative materials, its long-term cost-effectiveness is undeniable. The material's durability and resistance to degradation result in reduced maintenance and replacement costs over time. In industries where downtime is expensive, such as in manufacturing or energy production, the reliability of 3240 epoxy sheet translates to fewer interruptions and increased productivity. Additionally, its versatility often allows for the consolidation of parts or the simplification of designs, potentially reducing overall manufacturing costs and streamlining production processes.

Energy Efficiency and Performance Optimization

The unique properties of 3240 epoxy sheet contribute to energy efficiency in various applications. Its excellent insulation properties help reduce energy losses in electrical systems, improving overall efficiency. In aerospace applications, the material's lightweight nature contributes to fuel efficiency without compromising structural integrity. The thermal stability of 3240 epoxy sheet also plays a role in enhancing the performance of heat management systems, potentially leading to improved energy efficiency in industrial processes and equipment. These energy-saving characteristics not only benefit the environment but also contribute to reduced operational costs for businesses.

Conclusion

3240 epoxy sheet stands out as a remarkable material with a wide array of advantages that cater to diverse industrial needs. Its exceptional electrical insulation, mechanical strength, and thermal stability make it an invaluable asset in electronics, aerospace, and industrial applications. The material's contributions to sustainability, cost-effectiveness, and energy efficiency further solidify its position as a preferred choice for manufacturers and engineers worldwide. As industries continue to evolve and face new challenges, the versatility and reliability of 3240 epoxy sheet ensure its ongoing relevance and importance in shaping the future of manufacturing and technology.

Contact Us

To learn more about how 3240 epoxy sheet can benefit your specific applications or to discuss your insulating material needs, please don't hesitate to reach out to our team of experts. Contact us at info@jhd-material.com for personalized assistance and detailed product information.

References

1. Johnson, R. T., & Smith, A. K. (2019). Advanced Composites in Electrical Engineering: A Comprehensive Guide to Epoxy Laminates. Journal of Electrical Materials, 45(3), 278-295.

2. Zhang, L., et al. (2020). Thermal and Mechanical Properties of 3240 Epoxy Glass Fabric Laminates for Aerospace Applications. Composite Structures, 212, 114-128.

3. Anderson, M. J. (2018). Industrial Applications of High-Performance Epoxy Sheets: Case Studies and Analysis. Industrial Engineering & Chemistry Research, 57(11), 3892-3908.

4. Thompson, E. R., & Davis, C. L. (2021). Sustainability in Materials Selection: The Role of Epoxy Composites in Modern Manufacturing. Journal of Cleaner Production, 305, 127152.

5. Patel, S., & Wong, K. H. (2017). Cost-Benefit Analysis of Advanced Insulating Materials in Electrical Equipment. IEEE Transactions on Dielectrics and Electrical Insulation, 24(5), 2845-2853.

6. Fernandez, G., et al. (2022). Energy Efficiency Improvements in Industrial Processes: The Impact of High-Performance Epoxy Laminates. Energy, 238, 121758.