Epoxy Resin Industry Chain Map

2021-10-11

What is epoxy resin?

Epoxy resin is a gligenic compound containing two or more epoxy groups in a general mean, and the most widely used epoxy resin variety in the world is bisphenol A epoxy resin, accounting for 80% of total consumption.

There are more types, and the epoxy resin is used as its classification basic unit in the general industry. details as follows:

Classification by Form | Classified by Usage | Classified by Ingredients |

Flame retardant epoxy resin | Epoxy resin for electrical and electrical | Low bromide |

Liquid epoxy resin | Epoxy resin for basic usage | Bisphenol A |

Solvent epoxy resin | Epoxy resin for composite materials | Bisphenol A |

Solid-state epoxy resin | Special paint epoxy resin | Bisphenol A |

Other epoxy resin | Epoxy resins for other usage | Other epoxy resin |

Chemical Property

The epoxy resin has high mechanical properties, strong internal strength, molecular structure dense; excellent adhesive performance; small curing shrinkage is small (product size is stable, not easy to crack); good insulation; good stability; The thermal property is good (up to 200 ° C or higher), so the epoxy resin is widely used in various fields such as electron electrical, coating, composite materials, including electrical insulation and packaging materials, coatings, composites, and viscous. Take material, etc.

Chemical System

Epoxy resin is a thermoplastic oligomer, which is a substance of a variety of forms such as liquid, viscous or solid state. The epoxy resin itself has almost no single use value, except for the stabilizers of polyvinyl chloride, generally and the additives can be used simultaneously to obtain the application value.

Common additives have the following categories:

A, curing agent: The epoxy resin itself has thermoplastic, not solidified under normal temperature and general heating conditions, and cannot be directly applied to the field of material. Therefore, the epoxy resin must be added to the curing agent, formulating a formulation resin, and performing a curing reaction under certain conditions, the product of the veneer mesh structure will show various excellent properties, and become an epoxy material that truly use value.

B, diluent and solvent: Both are used in the field of epoxy resin production to mix components such as epoxy resin monomers, and the function of low curing system, increase fluidity. While improving operational, it is easy to construct the basic properties of the cured product.

Upstream Product of Epoxy Resin

The upstream of epoxy resins is mainly epoxy chloropropane and bisphenol A.

Epoxy chloropropane: epoxy chloropropane is an organochlorine compound and an epoxide. It is a colorless liquid, there is a stimulating odor similar to garlic, insoluble in water, but can be miscible with most polar organic solvents. Epoxy chloropropane is very active and is used to produce glycerin, plastic and artificial rubber. If contacted with water, epoxy chloropropane can hydrolyze 3-MCPD, which is a carcinogen found in food.

Bisphenol A: bisphenol A, also known as BPA, is an important derivative of organic chemical raw materials, phenol and acetone, mainly used to produce polycarbonate, epoxy resin, polysulfone resin, polyphenylene ether resin, etc. Polymer Materials. It is also available in plasticizers, flame retardants, antioxidants, thermal stabilizers, rubber anti-aging agents, pesticides, coatings and other fine chemical products.

Upstream Synthesis Process

According to the synthetic route, it is mainly divided into addition polymerization method and polycondensation method. At present, the mainstream domestic mainstream is an addition polymerization method. Among them, 1 ton of epoxy resin, a single consumption of 0.57 tons of epoxyhydroopropane and 0.68 tons of bisphenol A, and 0.39 tons of cyclopropane and 0.78 tons of bisphenol A using the polycondensation method. The mainstream process of the country is an addition polymerization method.

Downstream Products of Epoxy resin (application areas)

Coatings: Since the epoxy resin has excellent anti-corrosion resistance and chemical resistance, it is mainly used as a film formation substance, including ships and marine engineering, car electrophoretic paint, home appliances, IT products and other metal surfaces. Powder coatings, canned coatings, and ultraviolet photocurable coatings and aqueous epoxy coatings.

Electronic Appliance: Since excellent insulation performance, epoxy resin is used as a substrate with copper plate, and the copper plate is almost applied to each electronic product as the base material of the printed circuit board, which is an epoxy resin in electrical industrial consumption. The largest application area; second is a package for various electronic parts, including a high-pressure package, capacitor, and an encapsulation material for use with a conventional image tube display; a large amount of epoxy plastic sealing material in the package of semiconductor and integrated circuits.

Composite: Epoxy resin has excellent strength weight ratio, high temperature and corrosion resistance and other properties, is an ideal raw material for manufacturing composite materials like FR4 sheet, has a wide range of applications in civil and aviation, aerospace and military. Epoxy composites are mainly used as structural parts and solid rocket engine housings such as wind turbine blades, aircraft, satellite, and spacecraft. In the civilian field, epoxy composites are mainly used as badminton rackets and tennis rackets, golf clubs, fishing rods, snowboards, carbon fiber bicycles, rowing, etc., high-level sports and daily necessities.

Adhesive: Epoxy resin is not good in addition to non-polar plastic adhesion to polyolefins, for various metal materials such as aluminum, steel, iron, copper; non-metallic materials such as glass, wood, concrete, etc. The thermosetting plastic such as phenol, amino, unsaturated polyester, etc. has excellent bonding properties, so there is a high glue.

In 2018, the total demand for epoxy resin in my country was 15.12 million tons, of which the total demand in the coating is 7.091 million tons, and the demand in electronic and electrical and electrical and electrical and electrical and electrical appliances is 412,800 tons, and the demand for composite materials is 347,800 tons.

In 2018, the total demand for epoxy resin in my country was 15.12 million tons, of which the total demand in the coating is 7.091 million tons, and the demand in electronic and electrical and electrical and electrical and electrical and electrical appliances is 412,800 tons, and the demand for composite materials is 347,800 tons.

China epoxy resin production capacity

The production capacity of China's epoxy resin is mainly distributed in Jiangsu, Anhui Huangshan, Shandong, Guangdong and other provinces and cities. Among them, the large-scale device of Jiangsu region is more concentrated. The capacity of capacity has reached 52% of the country, and the rest is relatively fragmented, but more and downstream The demand correspondence, the Yangtze River Delta and the Pearl River Delta are the most concentrated regions of the domestic epoxy resin.

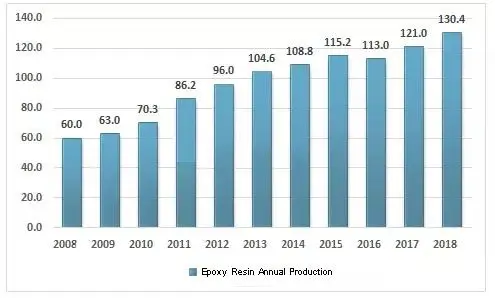

According to public information, my country's epoxy resin production capacity is about 2.3 million tons, and China's output is 1.21 million tons. In 2018, my country's epoxy resin production was approximately 1.324,000 tons, and the domestic epoxy resin product was mainly low-end. Composite materials with high technical content need to be rely on imported.

2008-2018 Chinese epoxy production chart

|

According to Customs Statistics: In 2018, the number of epoxy resin in my country was 2.74 million tons, and the number of exports was 58,000 tons. In 2018, my country's epoxy resin applause consumption was 15.12 million tons in 2018.

Epoxy Resin Industry Development Trend

The overall trend of global epoxy resin development in the future: production capacity continues to grow; production trend is concentrated; product is serialized, functionalized. Overall, the future development trend of the global epoxy resin industry in the future is mainly presented:

1 technology

In the field of coatings, epoxy resin materials develop in a high solid content, no solvent-free and water soluble direction; in the field of electron and electrical, packet sealing materials, development of flame retardant, low absorption, low viscosity and high density.

2 regional structure

At present, the development of the epoxy resin market in the developed country has reached the saturation. The future target market is mainly the Asian market, especially the Chinese market, and the demand for epoxy resins is large.

3 demand structure

Since the resin group composite materials are widely used in many areas such as aerospace, playgrounds, and mechanical fasteners, the demand for epoxy resins will increase by about 10%, especially in the Asia-Pacific region, especially in Taiwan. And continental, with the rapid increase in the output of electronic and electrical appliances, the amount of epoxy resin in this field is most likely to rapidly improve; automotive, industrial products, and civil engineering industries will stimulate the demand for epoxy resin growth, including laminate, coatings, adhesives, Floor, etc.