Can Epoxy Glass Fiber Sheets be used for PCBs?

2024-06-20 15:43:41

Epoxy Resin Sheets are an essential part in present day gadgets fabricating, especially in the domain of printed circuit sheets (PCBs). In this article, we dive into the inquiry: Will Epoxy Glass Fiber Sheets be utilized for PCBs? Through an exhaustive investigation of the properties, applications, benefits, and contemplations encompassing these materials, we expect to give a careful comprehension to producers and lovers the same.

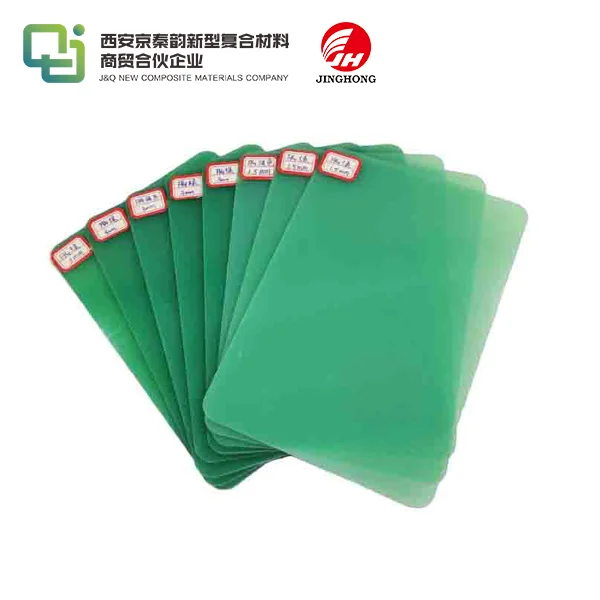

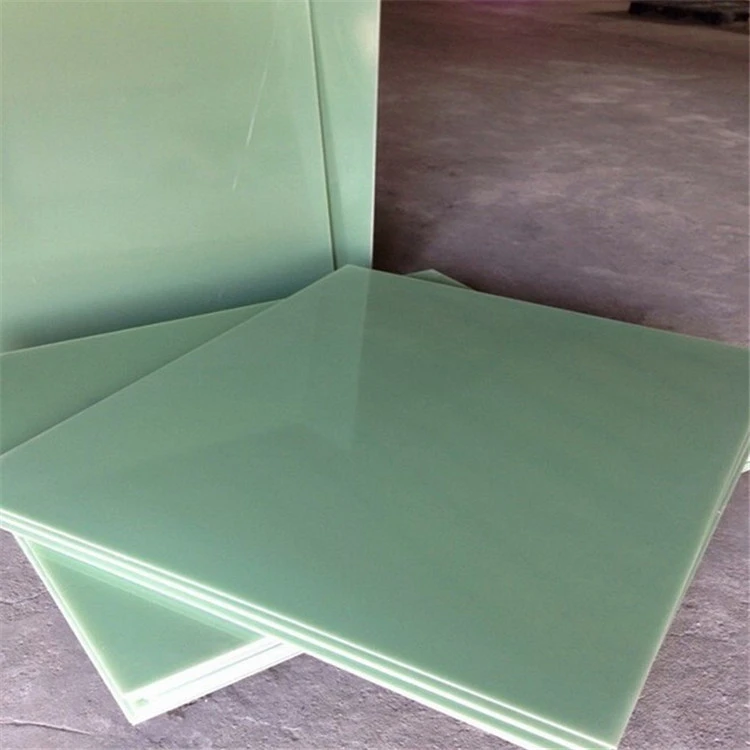

Understanding Epoxy Glass Fiber Sheets

Epoxy Glass Fiber Sheets, known as FR4 (Heat proof 4), are composite materials including woven fiberglass texture submerged with an epoxy gum folio. This wonderful mix yields a generous, persevering, and heat proof material that holds gigantic utility across various organizations like contraptions, vehicle, flying, and improvement.

The properties of the fiber sheets make them particularly sought after in current applications. Their extraordinary strength and robustness make them ideal for use in printed circuit sheets (PCBs) inside the equipment region, offering trustworthy security and mechanical assistance. In the auto business, FR4 sheets are utilized for parts requiring high mechanical strength and security from power and manufactured substances.Moreover, the heat proof nature of FR4 sheets further develops prosperity in applications where fire gambles are a concern, similar to flying and improvement.

Properties of Epoxy Glass Fiber Sheets Relevant to PCBs

Epoxy Glass Fiber Sheets are an exceptionally reasonable decision for PCBs because of a scope of key properties that they have. One of their principal credits is their remarkable electrical protection properties, which make them appropriate for filling in as substrates in the assembling of PCBs. This quality guarantees that the sheets can successfully disconnect and safeguard the electrical parts inside the PCB, subsequently adding to the board's general presentation and security.

Notwithstanding their electrical protection abilities, Epoxy Resin Sheets gloat high mechanical strength and layered steadiness, the two of which are significant variables in keeping up with the respectability of the PCB all through the manufacture cycle and during its functional life expectancy. The vigorous mechanical strength assists the PCB with enduring mechanical burdens and ecological variables, while the layered security guarantees that the sheet keeps up with its shape and structure, limiting the gamble of twisting or misshapening during use.

Moreover, these sheets offer great synthetic opposition, giving security against the possibly harming impacts of different synthetics and natural variables. This property improves the life span and unwavering quality of PCBs, permitting them to work actually in assorted and testing conditions without undermining their primary trustworthiness or electrical execution.

Application of Epoxy Glass Fiber Sheets in PCB Manufacturing

Epoxy Glass Fiber Sheets are an exceptionally reasonable decision for PCBs because of a scope of key properties that they have. One of their principal credits is their remarkable electrical protection properties, which make them appropriate for filling in as substrates in the assembling of PCBs. This quality guarantees that the sheets can successfully disconnect and safeguard the electrical parts inside the PCB, subsequently adding to the board's general presentation and security.

Notwithstanding their electrical protection abilities, Epoxy Glass Fiber Sheets gloat high mechanical strength and layered steadiness, the two of which are significant variables in keeping up with the respectability of the PCB all through the manufacture cycle and during its functional life expectancy. The vigorous mechanical strength assists the PCB with enduring mechanical burdens and ecological variables, while the layered security guarantees that the sheet keeps up with its shape and structure, limiting the gamble of twisting or misshapening during use.

Moreover, these sheets offer great synthetic opposition, giving security against the possibly harming impacts of different synthetics and natural variables. This property improves the life span and unwavering quality of PCBs, permitting them to work actually in assorted and testing conditions without undermining their primary trustworthiness or electrical execution.

Advantages and Disadvantages of Using Epoxy Glass Fiber Sheets for PCBs

The utilization of the fiber sheets in PCBs offers several advantages. Firstly, their high mechanical strength enhances the durability and reliability of the resulting circuit boards, reducing the likelihood of damage during handling and operation. Additionally, the excellent dimensional stability of these sheets contributes to the precise alignment of PCB layers, essential for achieving optimal electrical performance.

However, it is important to consider the limitations of Epoxy Glass Fiber Sheets as well. One notable disadvantage is their relatively high moisture absorption rate, which can lead to dimensional changes and compromised electrical properties in humid environments. Furthermore, the glass transition temperature of the epoxy resin binder imposes a thermal limitation on PCBs constructed with these materials, necessitating careful thermal management in high-temperature applications.

Considerations for Selecting Epoxy Glass Fiber Sheets in PCB Production

When selecting Epoxy Resin Sheets for PCB production, several factors must be taken into account. These include the desired electrical performance, mechanical requirements, thermal considerations, and environmental conditions of the end application. Additionally, considerations such as cost-effectiveness and availability of specific grades and thicknesses should be weighed to ensure optimal outcomes.

In conclusion, Epoxy Glass Fiber Sheets represent a versatile and widely used material in the fabrication of PCBs. Their combination of electrical insulation, mechanical strength, and dimensional stability makes them well-suited for a variety of electronic applications. By understanding the properties, applications, advantages, and limitations of these materials, manufacturers can make informed decisions to achieve optimal results in PCB production.

Contact us:

For professional manufacturing services, we invite you to contact us at info@jhd-material.com. As a GMP factory with a large inventory and complete certificates, we support OEM production with fast delivery and tight packaging. Partner with us to access top-quality materials and support for your electronic manufacturing needs.

References:

- Lee, C.K., Kim, Y.C., & Yoon, K.C. (2010). A Study on the Manufacturing Process of Epoxy/Glass Fiber Composite. Journal of Advanced Manufacturing Systems, 9(2), 103-111.

- Tarus, B.K., & Kipsang, J.K. (2018). Comparative Analysis of Different Dielectric Materials for PCB Substrate. International Journal of Engineering and Advanced Technology, 7(6), 238-242.

- Sabet, E.M., Ghorbanian, A., & Ahmadi, A. (2016). Investigation of the Effects of Epoxy Resin Composition on the Properties of Glass Fiber Reinforced Composites. Materials & Design, 102, 145-153.

- Zhang, X., & Wu, W. (2013). Analysis of Electrical Insulation Properties of FR4 Epoxy Resin Composite. Advanced Materials Research, 774-776, 1666-1671.

- Lau, J.H. (Ed.). (2018). Printed Circuit Boards: Design, Fabrication, and Assembly. McGraw Hill Professional.

拷贝.webp)