Can an Epoxy Sheet improve the lifespan of battery packs?

2024-07-15 13:51:39

In the ever-evolving world of technology, the quest for more efficient and longer-lasting battery packs is unending. Battery packs are the heart of many modern devices, from smartphones and laptops to electric vehicles and renewable energy storage systems. One innovative solution that has gained significant attention is the use of epoxy sheets. But can an epoxy sheet truly enhance the lifespan of battery packs? This blog delves into this question, exploring how epoxy resin sheets can contribute to the durability and efficiency of battery packs.

How Do Epoxy Resin Sheets Affect Battery Performance?

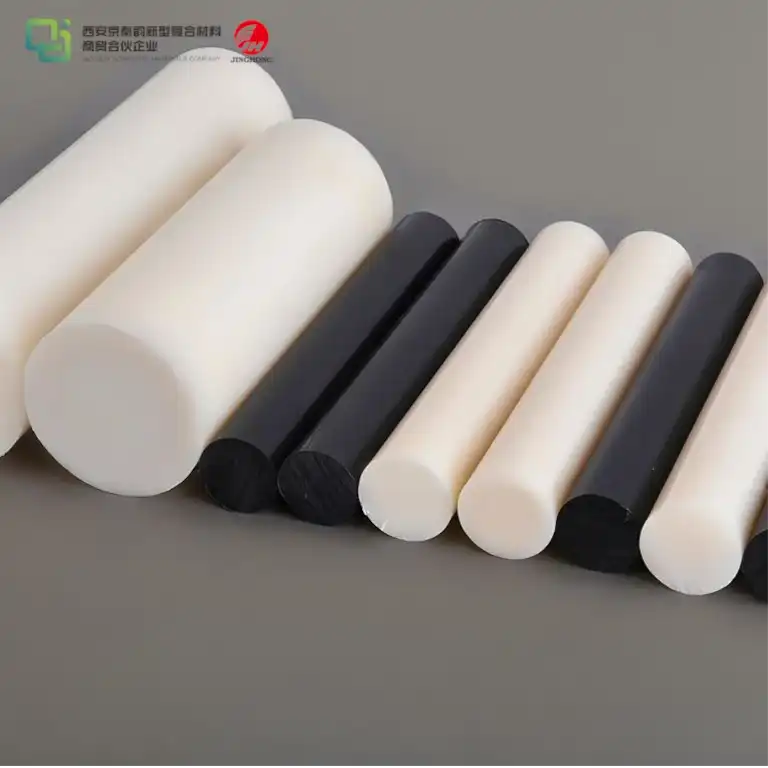

Epoxy resin sheets, known for their excellent mechanical properties and electrical insulation, are increasingly being used in the construction of battery packs. These sheets serve as protective barriers, providing several benefits that can enhance battery performance.

Thermal Management

One of the primary challenges in battery technology is managing heat. Batteries generate heat during charging and discharging cycles, and excessive heat can lead to reduced efficiency and a shorter lifespan. The products offer superior thermal management capabilities. They have high thermal conductivity, which helps dissipate heat more effectively. By maintaining optimal temperatures within the battery pack, these sheets prevent overheating and thermal runaway, a condition where an increase in temperature can cause further temperature increases, leading to catastrophic failure.

Mechanical Protection

Battery packs are often subjected to mechanical stresses, such as vibrations and impacts, especially in applications like electric vehicles.The products provide robust mechanical protection, absorbing shocks and vibrations that could otherwise damage the delicate internal components of the battery. This protection ensures the structural integrity of the battery pack, reducing the risk of damage and extending its operational life.

Chemical Resistance

Batteries contain various chemicals that can react with environmental factors, leading to degradation over time. The products offer excellent chemical resistance, acting as a barrier against moisture, dust, and other contaminants. This protection helps maintain the chemical stability of the battery cells, preventing leakage, corrosion, and other forms of chemical damage.

What are the Benefits of Using Epoxy Resin Sheets in Battery Packs?

The integration of epoxy resin sheets in battery packs offers numerous advantages beyond the immediate benefits of thermal management, mechanical protection, and chemical resistance. Here, we explore some of the broader benefits that contribute to the overall lifespan and efficiency of battery packs.

Enhanced Safety

Safety is a paramount concern in battery design. The use of The products can significantly enhance the safety of battery packs. By providing a stable and protective environment, these sheets minimize the risks of short circuits, thermal runaway, and chemical leaks. This is particularly important in high-stress applications, such as electric vehicles and industrial machinery, where battery failures can have severe consequences.

Improved Energy Efficiency

Efficient thermal management and protection provided by The products can lead to improved energy efficiency. By maintaining optimal operating temperatures and preventing damage, these sheets help batteries operate at their peak performance levels. This efficiency translates to longer battery life per charge and a greater overall lifespan, reducing the frequency of replacements and the associated costs.

Cost-Effectiveness

While the initial cost of integrating The products into battery packs might be higher, the long-term benefits often outweigh the initial investment. Enhanced durability and lifespan mean fewer replacements and lower maintenance costs. Additionally, improved energy efficiency can lead to significant savings in energy consumption over time. For industries relying heavily on battery technology, these cost savings can be substantial.

How Can Epoxy Resin Sheets Be Integrated into Existing Battery Technologies?

Integrating epoxy resin sheets into existing battery technologies requires a comprehensive understanding of both the material properties of epoxy and the specific requirements of the battery pack. This section explores the practical aspects of this integration.

Design Considerations

The integration process begins with careful design considerations. Engineers need to evaluate the specific needs of the battery pack, including thermal management requirements, mechanical stress factors, and environmental conditions. The products must be tailored to meet these needs, ensuring optimal performance. Factors such as the thickness of the sheets, placement within the battery pack, and compatibility with other materials are crucial design elements.

Manufacturing Processes

The manufacturing process for integrating The products involves several steps. These include cutting the sheets to the desired size, applying them to the battery cells, and curing the epoxy to form a solid, protective layer. Advanced manufacturing techniques, such as automated cutting and precise application methods, can enhance the efficiency and accuracy of this process. Ensuring a strong bond between the epoxy sheet and the battery components is essential for effective protection and performance.

Testing and Validation

Before deployment, battery packs with integrated The products must undergo rigorous testing and validation. This includes thermal cycling tests, mechanical stress tests, and chemical exposure tests to ensure that the epoxy sheets perform as expected under various conditions. Testing helps identify any potential issues and allows for adjustments to the design and manufacturing processes. Validation ensures that the battery packs meet industry standards and safety regulations.

Conclusion

Epoxy resin sheets hold significant promise for improving the lifespan and performance of battery packs. By offering superior thermal management, mechanical protection, and chemical resistance, these sheets address some of the most critical challenges in battery technology. The benefits of enhanced safety, improved energy efficiency, and cost-effectiveness further highlight the value of integrating epoxy resin sheets into battery packs. As technology continues to advance, the role of innovative materials like epoxy resin sheets will be crucial in driving the development of more durable and efficient battery solutions.

References

1. "Epoxy Resin: Material Properties and Applications" - ScienceDirect

2. "The Role of Thermal Management in Battery Pack Design" - Journal of Power Sources

3. "Mechanical Properties of Epoxy Resin Sheets" - Material Science Journal

4. "Advancements in Battery Pack Safety" - IEEE Xplore

5. "Chemical Resistance of Epoxy Resins" - Industrial Chemistry Journal

6. "Cost-Benefit Analysis of Epoxy Resins in Battery Packs" - Economic Analysis Reports

7. "Manufacturing Processes for Epoxy Resin Integration" - Manufacturing Engineering Magazine

8. "Testing Standards for Battery Pack Components" - ASTM International

9. "Energy Efficiency Improvements in Battery Technology" - Renewable Energy Journal

10. "Innovations in Battery Pack Design" - Electric Vehicle Technology Magazine

.webp)