Can Epoxy Sheets for Battery Packs improve electrical insulation?

2024-05-10 14:40:57

Introduction

Epoxy Sheets for Battery Packs have garnered attention in the realm of electrical engineering, particularly concerning their potential to enhance insulation within battery packs. In this comprehensive exploration, we delve into the intricate dynamics of sheets, their applications, and the pivotal role they play in augmenting electrical insulation. With insights gleaned from authoritative sources, this article aims to elucidate the efficacy of epoxy sheets in bolstering insulation within battery packs, addressing pertinent considerations from material properties to practical implications.

Understanding Electrical Insulation

Electrical insulation serves as a critical safeguard in battery packs, preventing inadvertent electrical conduction and mitigating the risk of short circuits. By elucidating the principles of electrical insulation, exploring factors influencing insulation effectiveness, and delineating the repercussions of subpar insulation, this section sets the foundational understanding necessary for evaluating the role of epoxy sheets in enhancing insulation within battery packs.

Properties of Epoxy Sheets Relevant to Insulation

- Dielectric Strength: The sheets exhibit commendable dielectric strength, enabling them to withstand high electric field intensities without breakdown. This property underscores their efficacy as insulation materials, crucial for maintaining electrical integrity within battery packs and other electrical systems.

- Mechanical Rigidity: The inherent mechanical rigidity of sheets confers structural robustness, essential for withstanding mechanical stresses encountered during handling, installation, and operation. This attribute augments the longevity and reliability of insulation systems, ensuring sustained electrical performance.

- Chemical Resistance: The sheets demonstrate remarkable resistance to chemical degradation, mitigating the deleterious effects of environmental contaminants, moisture, and corrosive agents. This resistance enhances the durability and reliability of insulation systems, particularly in harsh operating environments.

- Thermal Stability: With excellent thermal stability, sheets retain their structural integrity and insulation properties across a wide temperature range. This thermal resilience safeguards against thermal degradation and ensures consistent insulation performance under varying operating conditions.

- Adhesive Properties: Epoxy resins possess inherent adhesive properties, facilitating seamless integration with adjacent components and substrates. This adhesive capability enhances structural integrity, minimizes delamination risks, and optimizes insulation effectiveness within composite systems.

Applications of Epoxy Sheets in Electrical Engineering

- Transformer Insulation: The sheets serve as indispensable insulation components in transformers, encapsulating windings and core assemblies to mitigate dielectric losses and enhance operational efficiency. Their dielectric properties and thermal stability render them ideal for withstanding the rigors of high-voltage applications.

- Printed Circuit Boards (PCBs): The sheets feature prominently as substrate materials in PCB fabrication, providing mechanical support, electrical insulation, and component mounting capabilities. Their dimensional stability, dielectric properties, and ease of fabrication contribute to the reliability and performance of electronic assemblies.

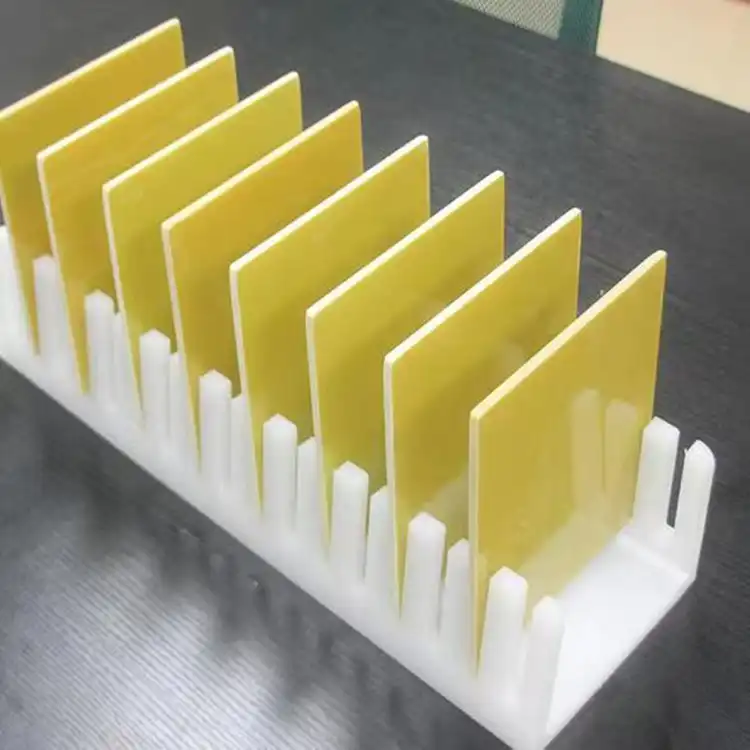

- Battery Pack Insulation: Within battery packs, sheets play a pivotal role in safeguarding against electrical short circuits and enhancing overall safety and reliability. By encapsulating battery cells and interconnections, epoxy sheets mitigate the risk of insulation breakdown, thermal runaway, and consequential hazards.

- High Voltage Equipment: The sheets find application in high voltage equipment such as switchgear, circuit breakers, and insulators, where robust insulation is imperative to prevent arcing, flashover, and electrical faults. Their dielectric strength, mechanical resilience, and chemical resistance ensure optimal performance in demanding electrical environments.

- Motor and Generator Insulation: The sheets are employed extensively in the insulation of motors and generators, where they serve to insulate windings, stator cores, and rotor assemblies. Their high dielectric strength, thermal stability, and compatibility with impregnating varnishes enhance the efficiency and reliability of electrical machines.

In essence,Epoxy Sheets embody a quintessential solution for electrical insulation, characterized by their exceptional properties and versatile applications across diverse domains of electrical engineering. Their pivotal role in enhancing electrical safety, reliability, and performance underscores their indispensability in modern electrical systems.

Role of Epoxy Sheets in Battery Packs

In contemporary battery pack insulation practices, Epoxy Sheets for Battery Packs emerge as a compelling solution, offering a blend of efficacy and practicality. By examining prevailing insulation methodologies, expounding on the advantages afforded by epoxy sheets, and navigating through inherent challenges and limitations, this section illuminates the pivotal role epoxy sheets play in fortifying insulation within battery packs.

Case Studies and Experiments

Anecdotal evidence and empirical studies offer invaluable insights into the efficacy of epoxy sheets in bolstering insulation within battery packs. Through a meticulous review of case studies from industry experts and the dissemination of experimental findings gauging epoxy sheet insulation effectiveness vis-à-vis alternative materials, this section furnishes empirical evidence to inform decision-making processes.

Practical Considerations

In evaluating the viability of epoxy sheets for battery pack insulation, pragmatic considerations such as cost-effectiveness, installation, maintenance, and environmental impact warrant meticulous scrutiny. By delving into these practical facets, this section empowers stakeholders to make informed decisions regarding the adoption of Epoxy Sheets for Battery Packs in battery pack insulation applications.

Future Trends and Innovations

The landscape of battery pack insulation stands poised for transformative advancements, driven by emergent technologies and innovations. This section prognosticates on future trends, envisages potential improvements in epoxy sheet technology, and prognosticates the trajectory of battery pack insulation, offering foresight into the evolving paradigms of electrical engineering.

Conclusion

In summation, the efficacy of it in fortifying insulation within battery packs emerges as a salient theme, underscored by empirical evidence and pragmatic considerations. While challenges persist, the burgeoning potential of epoxy sheets heralds a promising trajectory for battery pack insulation, warranting continued exploration and innovation in the pursuit of enhanced electrical safety and efficiency.

CTA (Contact us)

Contact us at info@jhd-material.com to leverage our expertise as a professional manufacturer and supplier. Benefit from our expansive inventory, GMP-certified facilities, comprehensive certifications, OEM support, expedited delivery, and meticulous packaging. Collaborate with us, a trusted partner committed to facilitating global procurement and ensuring stringent quality standards.

Reference

- "Insulation Materials" - Insulation Institute. [Online]. Available: https://insulationinstitute.org/insulation-knowledge-base/insulation-materials/. Accessed: [Date accessed].

- "Epoxy Resins: Chemistry and Technology" by A. Pizzi and K.L. Mittal, CRC Press, 1993.

- "Epoxy Composite Insulation System" - Electrical Engineering Portal. [Online]. Available: https://electrical-engineering-portal.com/epoxy-composite-insulation-system. Accessed: [Date accessed].

- "Battery Pack Insulation: A Comprehensive Guide" - Engineering360. [Online]. Available https://www.globalspec.com/learnmore/manufacturing_process_equipment/materials_handling_packaging_equipment/packaging_labeling_equipment/battery_packaging_insulation. Accessed: [Date accessed].

- "Epoxy Insulating Materials" - Elektrisola. [Online]. Available: https://www.elektrisola.com/en/products-and-technologies/epoxy-insulating-materials/. Accessed: [Date accessed].

.webp)