Can a Flame Resistance FR4 Fiber Glass Laminate Sheet be used for electrical insulation?

2024-05-15 15:32:00

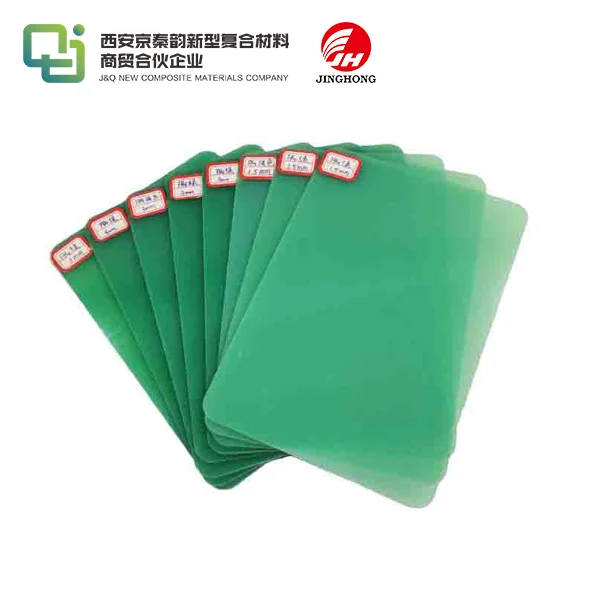

Flame Resistance FR4 Fiber Glass Laminate Sheet is a widely recognized glass-reinforced epoxy laminate material, known primarily for its extensive use in the manufacturing of printed circuit boards (PCBs). However, its properties extend beyond just PCB fabrication, making it a versatile choice for various applications, including electrical insulation. This article explores the suitability of FR4 for electrical insulation, detailing its properties, applications, and advantages in this role.

Understanding FR4 and Its Properties

- Material Composition

Fiberglass Cloth: FR4 is primarily composed of a woven fiberglass cloth. This fiberglass reinforcement provides strength, rigidity, and dimensional stability to the material.

Epoxy Resin Binder: The fiberglass cloth is impregnated with an epoxy resin binder. Epoxy resins are thermosetting polymers that provide adhesion, mechanical strength, and chemical resistance to the composite material.

Flame Retardant Additives: FR4 formulations incorporate flame retardant additives to enhance the material's fire resistance. These additives inhibit flame spread and reduce smoke generation during combustion.

- Properties

Electrical Insulation: FR4 offers excellent electrical insulation properties, making it suitable for use as a substrate material in PCBs and other electrical components. It prevents electrical shorts and ensures the integrity of electronic circuits.

Mechanical Strength: The fiberglass reinforcement provides FR4 with high mechanical strength and rigidity, allowing it to withstand bending, flexing, and mechanical stress. This property is crucial for structural support in electronic assemblies.

Dimensional Stability: FR4 maintains its dimensional stability over a wide range of temperatures and environmental conditions, ensuring consistent performance in various applications. It resists warping, shrinking, or expanding, even under thermal cycling.

Flame Resistance: FR4 materials exhibit flame resistance properties, especially those formulated with flame retardant additives. They resist ignition, inhibit flame spread, and reduce smoke generation during combustion, enhancing fire safety in electronic devices and systems.

Thermal Stability: While not as heat-resistant as some other materials, FR4 exhibits good thermal stability within moderate temperature ranges. It can withstand typical operating temperatures in electronic devices and assemblies without significant degradation.

Chemical Resistance: FR4 demonstrates resistance to many chemicals, making it suitable for use in environments where exposure to solvents, oils, and other chemicals is possible. This property enhances the material's durability and longevity in harsh operating conditions.

- Applications

FR4 materials find applications in various industries, including electronics manufacturing, aerospace, automotive, telecommunications, and industrial equipment.

They are commonly used in the fabrication of PCBs, electrical enclosures, switchgear, control panels, LED lighting systems, automotive components, aerospace structures, and more.

FR4's combination of electrical insulation, mechanical strength, dimensional stability, flame resistance, thermal stability, and chemical resistance makes it a versatile material for diverse applications in modern technology and engineering.

The Role of FR4 in Electrical Insulation

Due to its low dielectric constant and high dielectric strength, FR4 serves as an effective insulator, capable of preventing unintended electrical contacts and ensuring the safety and functionality of electrical and electronic devices. Its insulation properties are crucial in applications where components may generate heat or where high voltage levels are present (FR4 Material) (Wevolver).

Preventing Electrical Shorts:One of the primary functions of Flame Resistance FR4 Fiber Glass Laminate Sheet is to prevent electrical shorts between conductive traces, pads, and components on a PCB. The fiberglass reinforcement and epoxy resin matrix provide a non-conductive barrier between different electrical elements, ensuring that current flows along the intended pathways without unintended connections.

Ensuring Dielectric Strength:FR4 materials exhibit excellent dielectric strength, which is the ability to withstand electric fields without breakdown. This property is crucial for maintaining insulation integrity in high-voltage applications, preventing arcing and electrical discharge between conductive elements.

Supporting High-Frequency Signals:FR4 substrates are commonly used in high-frequency applications, such as RF (radio frequency) circuits and microwave devices. The low dielectric constant and low loss tangent of FR4 enable efficient transmission of high-frequency signals while minimizing signal distortion and attenuation.

Thermal Insulation:In addition to electrical insulation, FR4 materials also provide thermal insulation properties. They help dissipate heat generated by electronic components and prevent thermal interference between adjacent components. This thermal insulation helps maintain stable operating temperatures within electronic devices, enhancing their reliability and longevity.

Mechanical Support:FR4 substrates offer mechanical support to electronic components mounted on PCBs. They provide a rigid and stable platform for mounting and securing components, ensuring proper alignment and mechanical integrity of the assembly.

Environmental Protection:FR4 materials provide environmental protection for electronic components against moisture, dust, and other contaminants. The non-conductive nature of FR4 prevents short circuits and electrical malfunctions caused by environmental factors.

Compliance with Safety Standards:FR4 materials are manufactured to meet various safety standards and regulations governing electrical insulation properties. Compliance with these standards ensures that FR4-based PCBs and components meet prescribed safety requirements and perform reliably in their intended applications.

Advantages of Using FR4 for Electrical Insulation

FR4's popularity in electrical insulation can be attributed to several factors:

Thermal Stability: FR4 can withstand high temperatures without degrading, which is vital in environments where electronic components operate at elevated temperatures.

Flame Retardancy: As a flame-retardant material, FR4 enhances the safety of electronic devices by reducing the risk of fire hazards (Atlas Fibre).

Mechanical Durability: The glass reinforcement in FR4 provides substantial mechanical strength, which is beneficial in protecting and insulating delicate electronic components (Elecrow).

Limitations and Considerations for Using FR4

While FR4 is advantageous for many applications, it has its limitations. For instance, its thermal conductivity is relatively low, which might not be sufficient for high-power applications where efficient heat dissipation is crucial.

Moreover, in very high-frequency applications, materials with lower dissipation factors might be preferable due to reduced signal loss (Wevolver).

Alternative Materials to FR4 for Electrical Insulation

In scenarios where FR4 does not meet all the necessary criteria, alternative materials such as Polyimide, PTFE (Teflon), and metal-core PCBs (MCPCBs) are considered.

These materials offer higher thermal stability, better performance at high frequencies, or improved thermal conductivity, making them suitable for specific advanced applications (Wevolver).

Conclusion

Flame Resistance FR4 Fiber Glass Laminate Sheet is a robust material extensively used for electrical insulation due to its excellent dielectric properties, mechanical strength, and flame retardancy. However, understanding the specific requirements of your application is crucial to determine whether FR4 or an alternative material is the best choice.

As a professional manufacturer and supplier with extensive experience, we offer high-quality FR4 materials produced in our GMP-compliant factory. Our products come with full certifications, large stock levels, and we support OEM services with rapid delivery, secure packaging, and quality testing options. For more information or to discuss your requirements, please contact us.