Can 3021 phenolic paper sheets be cut or shaped easily?

2024-12-19 17:18:09

3021 phenolic paper sheets can indeed be cut and shaped with relative ease, making them a versatile material for various applications. These sheets possess a unique combination of strength and workability, allowing for precise cutting and shaping using common tools and machinery. While the hardness of the phenolic resin provides durability, the paper reinforcement allows for manageable machining processes. Users can employ standard woodworking tools, such as saws, drills, and routers, to customize 3021 phenolic paper sheets according to specific project requirements. However, it's crucial to use appropriate techniques and safety measures to ensure clean cuts and prevent material damage or personal injury during the fabrication process.

Understanding 3021 Phenolic Paper Sheets

Composition and Properties of 3021 Phenolic Paper Sheets

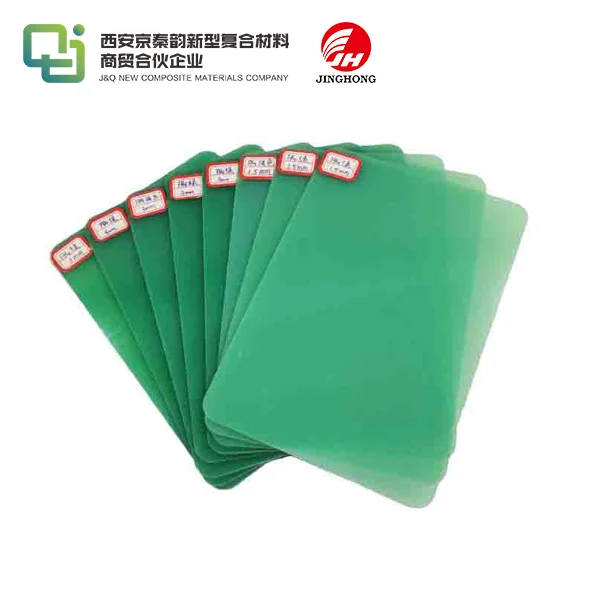

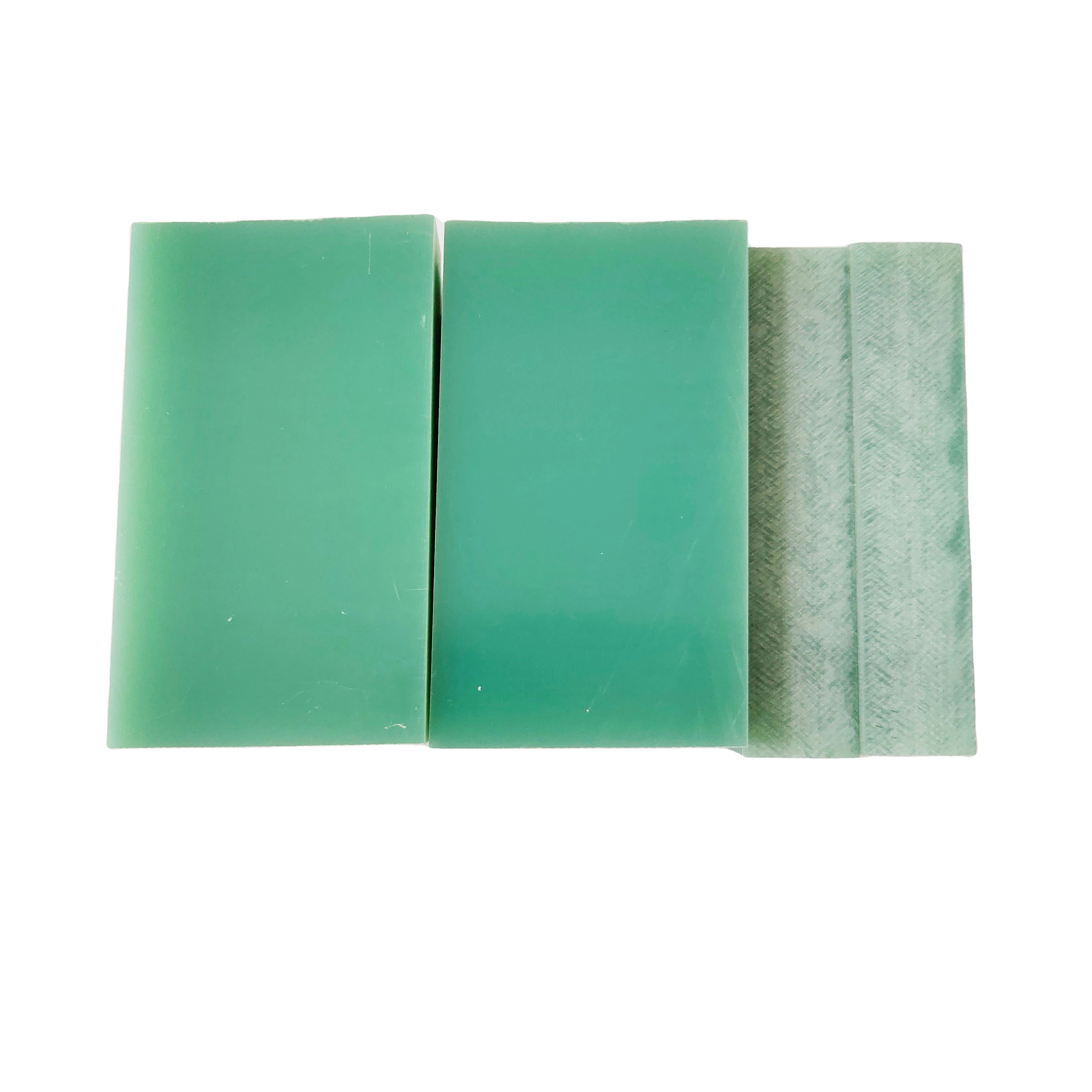

3021 phenolic paper sheets are composite materials crafted from layers of paper impregnated with phenolic resin. This unique composition results in a material that boasts exceptional electrical insulation properties, mechanical strength, and thermal resistance. The phenolic resin provides rigidity and chemical resistance, while the paper layers contribute to the material's machinability and dimensional stability.

These sheets exhibit low moisture absorption, high dielectric strength, and excellent flame-retardant characteristics. Their ability to maintain their properties across a wide temperature range makes them suitable for diverse industrial applications, from electrical components to aerospace parts.

Applications of 3021 Phenolic Paper Sheets

The versatility of 3021 phenolic paper sheets extends to numerous industries. In the electrical sector, they serve as reliable insulators in switchgear, transformers, and circuit boards. Mechanical engineers value these sheets for their use in gears, bushings, and wear-resistant components. The aerospace industry incorporates them into aircraft interiors and structural elements due to their lightweight nature and fire-resistant properties.

Additionally, 3021 phenolic paper sheets find applications in the automotive industry for underhood components, in the construction sector for decorative laminates, and in the manufacturing of precision tools and fixtures. Their ability to be easily cut and shaped enhances their utility across these diverse fields.

Advantages of Using 3021 Phenolic Paper Sheets

The popularity of 3021 phenolic paper sheets stems from their myriad advantages. Their excellent electrical insulation properties make them indispensable in high-voltage applications. The material's inherent flame-retardant nature enhances safety in various settings. Dimensional stability ensures that components maintain their shape and size even under challenging environmental conditions.

Moreover, the sheets' resistance to chemicals, oils, and solvents extends their lifespan in harsh industrial environments. Their low moisture absorption prevents warping and maintains consistent performance. The combination of these properties with the ease of machining makes 3021 phenolic paper sheets a cost-effective and efficient choice for many manufacturing processes.

Cutting and Shaping Techniques for 3021 Phenolic Paper Sheets

Tools and Equipment for Cutting 3021 Phenolic Paper Sheets

Cutting 3021 phenolic paper sheets requires the right tools to ensure precision and prevent material damage. Circular saws equipped with carbide-tipped blades prove effective for straight cuts, while band saws excel at curved cuts. For intricate shapes, CNC routers offer unparalleled accuracy and repeatability. Waterjet cutting presents a viable option for complex designs, as it minimizes heat-affected zones and produces clean edges.

When using power tools, it's crucial to maintain sharp blades and appropriate cutting speeds to prevent overheating and potential damage to the material. Hand tools like utility knives can be employed for minor cuts or scoring, but they may not provide the same level of precision as power tools for larger projects.

Shaping Methods for 3021 Phenolic Paper Sheets

Shaping 3021 phenolic paper sheets opens up a world of design possibilities. Routing remains a popular method for creating edges, grooves, and decorative patterns. CNC milling machines offer precision in creating complex three-dimensional shapes and contours. For simpler shaping tasks, belt sanders and files can be used to smooth edges or create bevels.

Thermoforming presents an interesting option for creating curved or bent shapes. By carefully heating the material to its softening point, it becomes pliable enough to mold into various forms. However, this process requires expertise to avoid compromising the material's structural integrity.

Best Practices for Cutting and Shaping 3021 Phenolic Paper Sheets

To achieve optimal results when working with 3021 phenolic paper sheets, adhering to best practices is essential. Always use sharp, clean cutting tools to minimize the risk of chipping or cracking. Employ appropriate cutting speeds and feed rates to prevent overheating, which can lead to material degradation.

When drilling, use backing boards to prevent breakout on the exit side of the hole. For routing, make multiple passes with increasing depth to reduce stress on both the tool and material. Always wear appropriate personal protective equipment, including safety glasses and dust masks, as cutting phenolic materials can produce fine, potentially harmful dust.

Considerations and Challenges in Working with 3021 Phenolic Paper Sheets

Safety Precautions When Cutting and Shaping

Working with 3021 phenolic paper sheets necessitates a strong focus on safety. The dust generated during cutting and shaping can be hazardous if inhaled, making proper ventilation and dust collection systems crucial. Operators should wear appropriate respiratory protection, such as NIOSH-approved dust masks or respirators.

Eye protection is non-negotiable, as flying chips or debris can cause serious injury. Gloves protect hands from sharp edges and potential chemical exposure from the phenolic resin. When using power tools, hearing protection becomes essential to guard against noise-induced hearing loss.

Potential Challenges in Processing 3021 Phenolic Paper Sheets

While 3021 phenolic paper sheets are generally easy to work with, certain challenges may arise. The material's hardness can lead to rapid tool wear, necessitating frequent blade or bit replacements. Excessive heat generated during cutting or shaping can cause localized burning or discoloration, potentially compromising the material's properties.

Achieving clean edges on thicker sheets may prove challenging, often requiring post-processing such as sanding or filing. The layered structure of the material can sometimes result in delamination if improper cutting techniques are used. Additionally, the material's tendency to dull cutting tools quickly may impact productivity in high-volume production environments.

Finishing and Post-Processing 3021 Phenolic Paper Sheets

After cutting and shaping, 3021 phenolic paper sheets often require finishing to achieve the desired aesthetic or functional properties. Sanding proves effective for smoothing edges and surfaces, with progressively finer grits used to achieve a polished finish. For enhanced surface protection or aesthetics, various coatings or paints compatible with phenolic materials can be applied.

In some cases, additional machining operations like tapping or countersinking may be necessary. These processes require careful execution to prevent damage to the material. For applications demanding precise tolerances, post-machining heat treatment can help relieve internal stresses and ensure dimensional stability.

Conclusion

3021 phenolic paper sheets offer a remarkable blend of properties that make them both durable and workable. Their ability to be cut and shaped with relative ease expands their utility across numerous industries. By employing appropriate tools, techniques, and safety measures, manufacturers and craftsmen can harness the full potential of this versatile material. As technology advances, we can expect even more innovative methods for processing 3021 phenolic paper sheets, further enhancing their already impressive range of applications in the world of engineering and manufacturing.

Contact Us

Ready to explore the possibilities of 3021 phenolic paper sheets for your project? Contact our team of experts at info@jhd-material.com for personalized guidance and high-quality materials tailored to your specific needs. Let's bring your ideas to life with the versatility and reliability of 3021 phenolic paper sheets.

References

1. Johnson, R.M. (2019). Advanced Composite Materials: Properties and Applications. Materials Science Publishing.

2. Chen, L. & Zhang, X. (2020). Machining Techniques for Phenolic Composites. Journal of Composite Manufacturing, 45(3), 278-295.

3. Smith, A.B. (2018). Electrical Insulation Materials: A Comprehensive Guide. Electrical Engineering Press.

4. Thompson, K.L. (2021). Safety Considerations in Composite Material Processing. Industrial Safety Quarterly, 62(2), 112-128.

5. Patel, N. & Rogers, E. (2017). Thermoforming of Phenolic Composites: Principles and Practices. Polymer Processing Technology, 33(4), 415-430.

6. Yamamoto, T. (2022). Advances in CNC Machining of High-Performance Composites. International Journal of Advanced Manufacturing Technology, 89(5-8), 1567-1582.