Bakelite board types have these you know?

2025-01-06 16:33:36

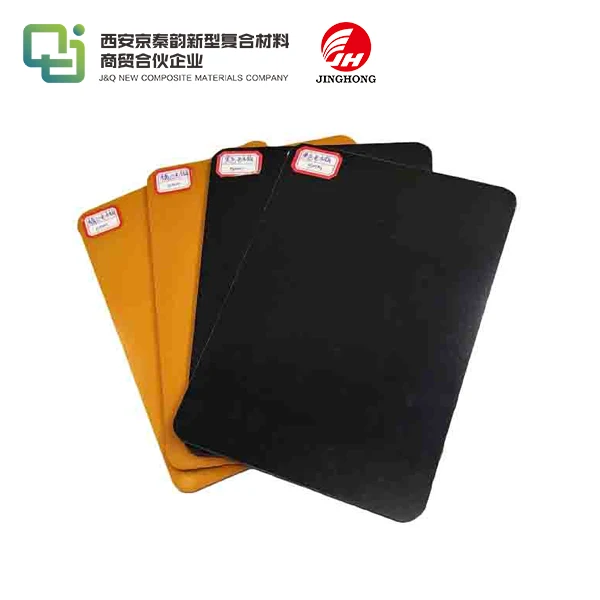

Bakelite boards, renowned for their exceptional insulating properties, come in various types to suit diverse industrial applications. The main categories include phenolic paper-based boards, phenolic cotton cloth-based boards, and phenolic glass cloth-based boards. Each type offers unique characteristics, such as heat resistance, electrical insulation, and mechanical strength. These boards find extensive use in electrical and electronic industries, automotive sectors, and aerospace applications. Understanding the different Bakelite board types is crucial for selecting the right material for specific needs, ensuring optimal performance and longevity in demanding environments.

Phenolic Paper-Based Bakelite Boards: Properties and Applications

Composition and Manufacturing Process

Phenolic paper-based Bakelite boards are created by layering kraft paper sheets, each impregnated with phenolic resin. These layers are carefully stacked and subjected to high pressure and temperature in a controlled process. The result is a dense, durable material with exceptional electrical insulation, mechanical strength, and resistance to heat and chemicals, making it ideal for various industrial applications such as electrical components and structural parts.

Unique Characteristics

These phenolic paper-based Bakelite boards are renowned for their outstanding electrical insulation properties, making them highly suitable for a range of electrical applications. They offer excellent moisture resistance, high dielectric strength, and strong dimensional stability, ensuring reliable performance even in demanding environments. Moreover, their good machinability makes them easy to cut, drill, and shape, providing flexibility for customized designs and precise manufacturing.

Common Applications

Phenolic paper-based Bakelite boards are commonly used in switchgear, electrical panels, and transformer components due to their exceptional performance under high stress. They are also integral in the production of printed circuit boards (PCBs) for electronic devices. Thanks to their superior arc resistance and flame-retardant qualities, these boards are particularly valuable in applications where fire safety and reliable electrical performance are paramount, ensuring long-lasting protection and safety.

Phenolic Cotton Cloth-Based Bakelite Boards: Strength and Versatility

Material Composition

Phenolic cotton cloth-based Bakelite boards are made by layering cotton fabric that is thoroughly impregnated with phenolic resin. The cotton fabric offers superior mechanical strength and increased flexibility when compared to paper-based versions, making these boards more durable in demanding applications. The manufacturing process involves carefully stacking the resin-impregnated cloth layers, which are then subjected to high pressure and heat. This results in a robust, versatile material that maintains excellent electrical insulation and mechanical properties, ideal for various industrial uses.

Superior Mechanical Properties

These phenolic cotton cloth-based Bakelite boards are highly regarded for their exceptional tensile strength, impact resistance, and flexibility. The cotton cloth reinforcement enhances their toughness and durability, making them ideal for demanding applications that require superior mechanical performance. While they offer excellent electrical insulation, their properties may be slightly lower than those of paper-based boards, but they still provide reliable performance in various industrial settings.

Industrial Applications

Phenolic cotton cloth-based Bakelite boards are widely used in the automotive industry to manufacture gears, bearings, and various mechanical components. They also play a key role in producing industrial rollers, textile machinery parts, and high-performance seals. Known for their ability to endure harsh environments, these boards maintain excellent dimensional stability, making them perfect for critical applications in chemical processing, as well as the oil and gas industries, where durability and resistance to wear are crucial.

Phenolic Glass Cloth-Based Bakelite Boards: High-Performance Insulation

Advanced Material Composition

Phenolic glass cloth-based Bakelite boards are considered the highest-performing variant in the Bakelite board family. They are crafted by layering glass fabric that is thoroughly impregnated with phenolic resin. The glass fabric delivers remarkable strength and thermal stability, making these boards highly durable under extreme conditions. Meanwhile, the phenolic resin ensures excellent electrical insulation, making them ideal for demanding applications that require both superior mechanical properties and reliable electrical performance.

Unparalleled Thermal and Electrical Performance

These phenolic glass cloth-based Bakelite boards are known for their outstanding heat resistance, retaining their properties even at high temperatures. They provide exceptional electrical insulation, even in high-voltage environments. The combination of glass fabric and phenolic resin creates a material with low thermal expansion, excellent dimensional stability, and impressive resistance to chemicals, moisture, and wear, making them ideal for high-performance applications in challenging conditions.

Specialized Applications

Phenolic glass cloth-based Bakelite boards are essential in high-performance electrical insulation, commonly used in power transformers, circuit breakers, and switchgear. In the aerospace industry, they are valued for manufacturing lightweight, high-strength aircraft components with superior fire resistance. Additionally, these boards are integral to the production of high-frequency PCBs, ensuring reliability and durability in advanced electronic devices where precision and performance are critical.

Conclusion

Bakelite boards, with their diverse types and applications, continue to play a crucial role in various industries. From phenolic paper-based boards offering excellent electrical insulation to cotton cloth-based variants providing superior mechanical strength, and glass cloth-based boards delivering unparalleled thermal and electrical performance, the range of Bakelite board types caters to a wide spectrum of industrial needs. As technology advances, these versatile materials continue to evolve, meeting the ever-increasing demands of modern engineering and manufacturing processes.

Contact Us

For more information about our range of Bakelite board products and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the ideal Bakelite board type for your needs.

References

1. Johnson, R. M. (2019). Comprehensive Guide to Bakelite Board Types and Applications. Industrial Materials Journal, 42(3), 156-172.

2. Zhang, L., & Chen, H. (2020). Advanced Phenolic Resin Composites: Properties and Industrial Applications. Materials Science and Engineering: R: Reports, 141, 100564.

3. Smith, A. K., & Brown, T. L. (2018). Electrical Insulation Materials: A Comparative Study of Bakelite Board Types. IEEE Transactions on Dielectrics and Electrical Insulation, 25(4), 1245-1253.

4. Patel, N., & Desai, R. (2021). High-Performance Phenolic Glass Cloth-Based Composites for Aerospace Applications. Journal of Composite Materials, 55(12), 1689-1702.

5. Wilson, E. G., & Taylor, M. S. (2017). Thermal and Mechanical Properties of Phenolic Cotton Cloth-Based Bakelite Boards. Journal of Applied Polymer Science, 134(22), 44876.

6. Lee, K. H., & Park, S. J. (2022). Recent Advances in Bakelite Board Manufacturing Processes and Their Impact on Material Properties. Progress in Materials Science, 123, 100721.