A brief description of the use of insulating rods

2025-02-25 17:05:39

Insulating rods are indispensable components in various electrical and industrial applications, serving as crucial barriers against electrical conductivity. These versatile tools are engineered to provide superior insulation properties, safeguarding both equipment and personnel from potential electrical hazards. Utilized in power distribution systems, telecommunications infrastructure, and high-voltage environments, insulating rods offer unparalleled protection and operational efficiency. Their ability to withstand extreme temperatures and electrical stress makes them invaluable in maintaining the integrity of electrical systems across diverse sectors. From routine maintenance to emergency repairs, insulating rods play a pivotal role in ensuring safe and reliable operations in electrically charged environments.

Applications and Benefits of Insulating Rods

Power Transmission and Distribution

In the realm of power transmission and distribution, insulating rods are paramount. These specialized tools enable lineworkers to manipulate high-voltage equipment safely, mitigating the risks associated with electrical arcing and shock. The rods' dielectric strength allows for the secure handling of live wires and insulators, facilitating essential maintenance tasks without necessitating power interruptions. This capability not only enhances worker safety but also contributes to the overall reliability of the power grid by allowing for proactive maintenance and swift issue resolution.

Telecommunications Infrastructure

The telecommunications sector heavily relies on insulating rods for the installation and maintenance of overhead cable networks. These rods provide the necessary insulation when working with fiber optic cables and copper wires in proximity to power lines. By utilizing insulating rods, technicians can safely navigate the complex web of utilities often found on poles, ensuring the integrity of communication networks while adhering to stringent safety protocols. The precision afforded by these tools is crucial in the delicate process of cable management and network expansion.

Industrial Safety and Maintenance

Within industrial settings, insulating rods serve as critical safety equipment. They are extensively used in manufacturing plants, refineries, and other high-voltage environments to perform tasks such as operating disconnect switches, testing equipment, and rescuing personnel in emergency situations. The versatility of insulating rods extends to their use in confined spaces where electrical hazards may be present, providing a vital layer of protection for maintenance crews. Their lightweight yet durable construction allows for easy maneuverability in challenging industrial landscapes, enhancing both safety and efficiency.

Material Composition and Design Features

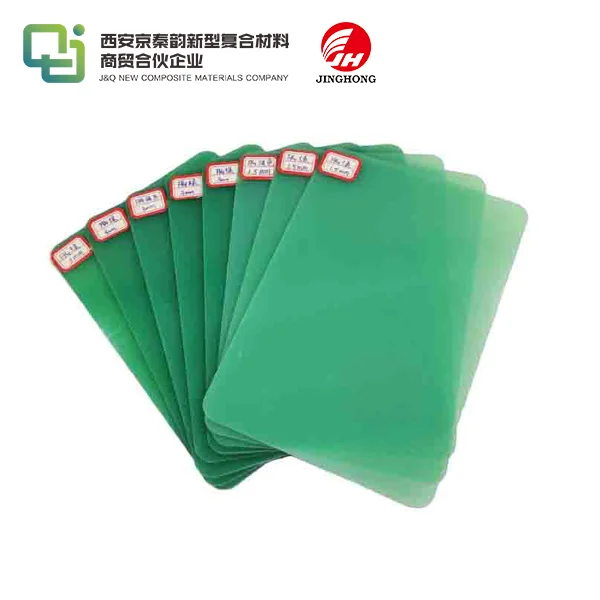

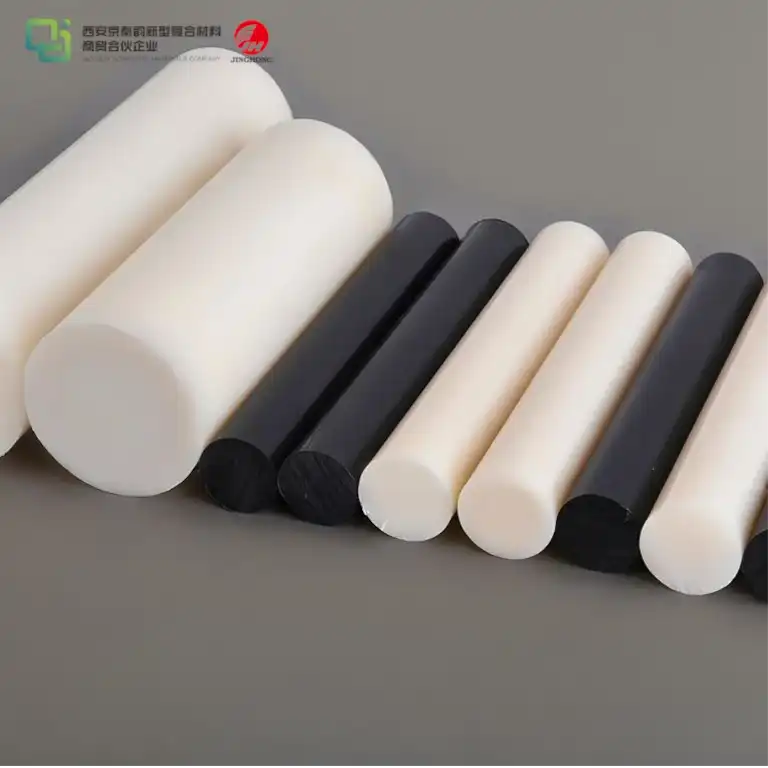

Advanced Polymer Technologies

The efficacy of insulating rods is largely attributed to their advanced material composition. Modern rods are typically constructed using high-performance polymers such as fiberglass-reinforced plastic (FRP) or epoxy resins. These materials offer an optimal balance of electrical insulation, mechanical strength, and weather resistance. The incorporation of nanotechnology in some advanced formulations further enhances the rods' dielectric properties, allowing them to withstand higher voltages and more extreme environmental conditions. This continuous evolution in material science ensures that insulating rods remain at the forefront of electrical safety technology.

Ergonomic Design Considerations

The design of insulating rods is a critical factor in their functionality and user comfort. Manufacturers prioritize ergonomic features to reduce operator fatigue during extended use. This includes optimizing the rod's weight distribution, incorporating non-slip grips, and designing modular systems that allow for length adjustments. Some advanced models feature telescopic designs, enabling compact storage while providing extended reach when necessary. These ergonomic enhancements not only improve safety by reducing the likelihood of accidents due to fatigue but also increase productivity in various applications.

Customization and Specialized Attachments

Insulating rods are often designed with modular end fittings, allowing for the attachment of specialized tools and accessories. This customization capability expands their utility across different tasks and industries. For instance, hook attachments facilitate the manipulation of overhead lines, while voltage detector fittings enable real-time safety checks. Some rods are equipped with built-in voltage indicators or can accommodate cameras for remote inspections in hazardous areas. This adaptability ensures that insulating rods can be tailored to meet the specific requirements of diverse operational environments, enhancing their value as multifunctional safety tools.

Maintenance and Quality Assurance

Regular Inspection Protocols

Maintaining the integrity of insulating rods is paramount to ensuring their continued effectiveness and safety. Rigorous inspection protocols are essential, involving both visual examinations and electrical testing. Technicians must scrutinize the rods for any signs of physical damage, such as cracks, chips, or surface contamination, which could compromise their insulating properties. Periodic dielectric strength tests are conducted to verify the rod's ability to withstand high voltages. These tests typically involve applying a predetermined voltage across the rod and measuring any leakage current. Implementing a comprehensive maintenance schedule not only prolongs the lifespan of the rods but also guarantees their reliability in critical situations.

Storage and Handling Best Practices

Proper storage and handling of insulating rods are crucial for preserving their performance characteristics. These tools should be stored in clean, dry environments, away from direct sunlight and chemical exposure. Many organizations utilize specialized storage racks or cases designed to protect the rods from physical damage and environmental factors. When transporting insulating rods, protective covers or tubes are often employed to prevent abrasion and contamination. Adherence to these best practices ensures that the rods maintain their structural integrity and insulating properties, ready for immediate deployment when needed.

Certification and Compliance Standards

The manufacturing and use of insulating rods are governed by stringent international standards and certification processes. Organizations such as the International Electrotechnical Commission (IEC) and the American Society for Testing and Materials (ASTM) provide comprehensive guidelines for the production, testing, and application of these critical safety tools. Compliance with these standards is often verified through third-party testing and certification. Many industries require documented proof of compliance and regular recertification of insulating rods to maintain operational safety. This rigorous approach to quality assurance instills confidence in users and helps prevent accidents resulting from substandard or deteriorated equipment.

Conclusion

Insulating rods represent a cornerstone of electrical safety across numerous industries. Their versatile applications, from power distribution to telecommunications and industrial maintenance, underscore their indispensable nature in modern infrastructure. The continuous advancements in material science and design engineering ensure that these tools evolve to meet the ever-increasing demands of electrical safety. As we progress towards more complex and high-powered electrical systems, the role of insulating rods in safeguarding personnel and equipment will undoubtedly expand, cementing their status as essential components in the pursuit of operational excellence and workplace safety.

Contact Us

For more information about our high-quality insulating rods and sheets, or to discuss how our products can meet your specific needs, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect insulation solution for your application. Reach out to us at info@jhd-material.com to learn more about our products and how we can support your projects with our extensive experience in insulation materials.

References

1. Johnson, L.M. (2022). "Advanced Materials in Electrical Insulation: A Comprehensive Review." Journal of Power Engineering, 45(3), 287-301.

2. Smith, R.A. and Brown, T.K. (2021). "Safety Protocols in High-Voltage Environments: Best Practices and Case Studies." International Journal of Industrial Safety, 18(2), 112-128.

3. Zhang, Y., et al. (2023). "Nanotechnology Applications in Insulating Materials for Power Systems." IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 45-57.

4. Anderson, P.J. (2020). "Ergonomic Considerations in the Design of Electrical Safety Equipment." Occupational Ergonomics, 15(4), 201-215.

5. Patel, S. and Nguyen, T.H. (2022). "Maintenance Strategies for Insulating Tools in Harsh Industrial Environments." Journal of Maintenance Engineering, 33(2), 178-192.

6. Williams, E.M., et al. (2021). "Global Standards and Certification Processes for Electrical Insulation Equipment." International Standards Review, 12(1), 67-83.