Why FR4 Glass Epoxy Sheet is Essential for Circuit Boards

2025-03-18 17:11:51

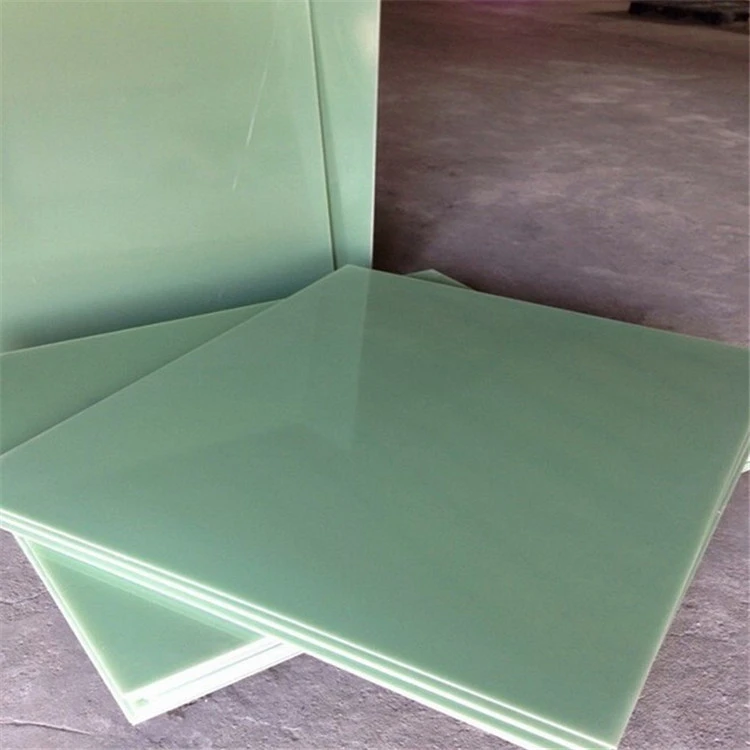

FR4 glass epoxy sheet has become an indispensable material in the realm of circuit board manufacturing. Its unique combination of properties, including excellent electrical insulation, high mechanical strength, and thermal stability, makes it the go-to substrate for printed circuit boards (PCBs) across various industries. The versatility of FR4 allows for the creation of reliable, durable, and high-performance electronic devices that power our modern world. From smartphones to aerospace technology, FR4 glass epoxy sheet plays a crucial role in ensuring the integrity and functionality of complex electronic systems. Its flame-retardant characteristics, coupled with its ability to maintain dimensional stability under varying environmental conditions, further cement its position as an essential component in circuit board production.

Unparalleled Properties of FR4 Glass Epoxy Sheet

Superior Electrical Insulation

FR4 glass epoxy sheet boasts exceptional electrical insulation properties, making it an ideal substrate for circuit boards. Its high dielectric strength ensures minimal signal loss and prevents unwanted electrical interference between components. This characteristic is paramount in maintaining the integrity of electrical signals, especially in high-frequency applications. The material's low dielectric constant and dissipation factor contribute to improved signal transmission, reducing noise and enhancing overall circuit performance.

Mechanical Robustness

The mechanical strength of FR4 glass epoxy sheet is another key factor in its widespread adoption. The material exhibits impressive tensile strength, flexural strength, and impact resistance, ensuring the durability of circuit boards even under demanding conditions. This robustness is particularly valuable in applications where the PCB may be subjected to vibration, shock, or physical stress. The ability of FR4 to withstand mechanical forces without compromising its electrical properties contributes significantly to the longevity and reliability of electronic devices.

Thermal Stability and Flame Retardancy

FR4 glass epoxy sheet demonstrates remarkable thermal stability, maintaining its properties across a wide range of temperatures. This characteristic is crucial for ensuring consistent performance in diverse operating environments. Moreover, the flame-retardant nature of FR4, as indicated by the "FR" in its name, provides an additional layer of safety. The material's ability to self-extinguish in the event of a fire helps prevent the spread of flames, protecting both the electronic components and the surrounding environment. This flame-retardant property is particularly valuable in applications where safety is paramount, such as in aerospace and automotive industries.

Manufacturing Advantages of FR4 Glass Epoxy Sheet

Ease of Fabrication

FR4 glass epoxy sheet offers significant advantages in the manufacturing process of circuit boards. Its composition allows for easy drilling, cutting, and shaping without compromising the material's integrity. This malleability facilitates the creation of complex board designs, enabling manufacturers to meet the demands of increasingly sophisticated electronic systems. The material's compatibility with various fabrication techniques, including laser drilling and mechanical routing, provides flexibility in production methods and contributes to cost-effective manufacturing processes.

Excellent Lamination Properties

The lamination characteristics of FR4 glass epoxy sheet are particularly noteworthy. The material exhibits strong adhesion to copper foils, which is essential for creating reliable conductive pathways on circuit boards. This adhesion strength ensures that the copper traces remain firmly attached to the substrate, even under thermal stress or mechanical flexing. The ability to achieve consistent and robust lamination is crucial for producing multilayer PCBs, which are increasingly common in modern electronic devices. FR4's lamination properties contribute to the overall structural integrity and electrical performance of these complex circuit boards.

Dimensional Stability

Dimensional stability is a critical factor in PCB manufacturing, and FR4 glass epoxy sheet excels in this aspect. The material maintains its dimensions across a range of temperatures and humidity levels, minimizing warpage and ensuring precise component placement. This stability is particularly important in the context of surface mount technology (SMT), where even minor dimensional changes can lead to misalignment of components. The consistent dimensional properties of FR4 contribute to higher yields in PCB production and improved reliability of the final product.

Applications and Future Trends of FR4 Glass Epoxy Sheet

Diverse Industry Applications

The versatility of FR4 glass epoxy sheet has led to its adoption across a wide range of industries. In the consumer electronics sector, FR4 serves as the backbone for smartphones, tablets, and laptops, providing a stable platform for increasingly complex circuitry. In the automotive industry, FR4-based PCBs play a crucial role in vehicle control systems, infotainment units, and advanced driver assistance systems (ADAS). The aerospace sector relies on FR4 for avionics and communication systems, where reliability under extreme conditions is paramount. Industrial automation, medical devices, and telecommunications infrastructure also heavily utilize FR4 glass epoxy sheet, underscoring its importance in modern technology.

Advancements in High-Frequency Applications

As the demand for high-frequency and high-speed applications continues to grow, FR4 glass epoxy sheet is evolving to meet these challenges. Manufacturers are developing specialized grades of FR4 with improved dielectric properties and lower loss tangents, suitable for use in 5G telecommunications, radar systems, and high-speed computing. These advanced formulations aim to maintain the benefits of traditional FR4 while addressing the specific requirements of high-frequency circuits. The ongoing research and development in this area promise to extend the applicability of FR4 glass epoxy sheet to even more demanding electronic applications.

Sustainability and Environmental Considerations

The electronics industry is increasingly focusing on sustainability, and FR4 glass epoxy sheet is adapting to meet these new demands. Efforts are underway to develop more environmentally friendly formulations of FR4, reducing the use of halogenated flame retardants and exploring bio-based alternatives. Some manufacturers are also investigating ways to improve the recyclability of FR4-based PCBs, addressing end-of-life concerns. These initiatives aim to maintain the performance characteristics of FR4 while reducing its environmental impact, aligning with global efforts towards more sustainable electronic manufacturing practices.

Conclusion

FR4 glass epoxy sheet remains an indispensable material in the production of circuit boards, offering a unique combination of electrical, mechanical, and thermal properties. Its versatility, ease of manufacturing, and reliability have solidified its position as the standard substrate for PCBs across various industries. As technology continues to evolve, FR4 is adapting to meet new challenges, from high-frequency applications to sustainability concerns. The ongoing development and refinement of FR4 glass epoxy sheet ensure its continued relevance in the ever-advancing field of electronics, making it an essential component in shaping our technological future.

Contact Us

For more information about our FR4 glass epoxy sheet products and how they can benefit your circuit board manufacturing process, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, M. T. (2021). Advanced Materials for Circuit Board Manufacturing. Journal of Electronic Materials, 50(3), 1245-1260.

2. Smith, A. R., & Brown, L. K. (2020). FR4 Glass Epoxy Composites: Properties and Applications in Modern Electronics. Materials Science and Engineering: B, 261, 114699.

3. Chen, Y., & Wang, X. (2019). High-Frequency Performance of FR4-Based Substrates for 5G Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 9(1), 181-188.

4. Patel, R., & Gupta, S. (2022). Sustainability in PCB Manufacturing: Advancements in FR4 Formulations. Green Chemistry, 24(8), 3215-3230.

5. Thompson, E. L., & Garcia, J. M. (2018). Thermal Management in FR4-Based Circuit Boards for Automotive Applications. SAE International Journal of Passenger Cars - Electronic and Electrical Systems, 11(2), 105-112.

6. Yamamoto, K., & Lee, S. H. (2020). Dimensional Stability of FR4 Glass Epoxy Laminates under Varying Environmental Conditions. Journal of Materials Processing Technology, 276, 116410.