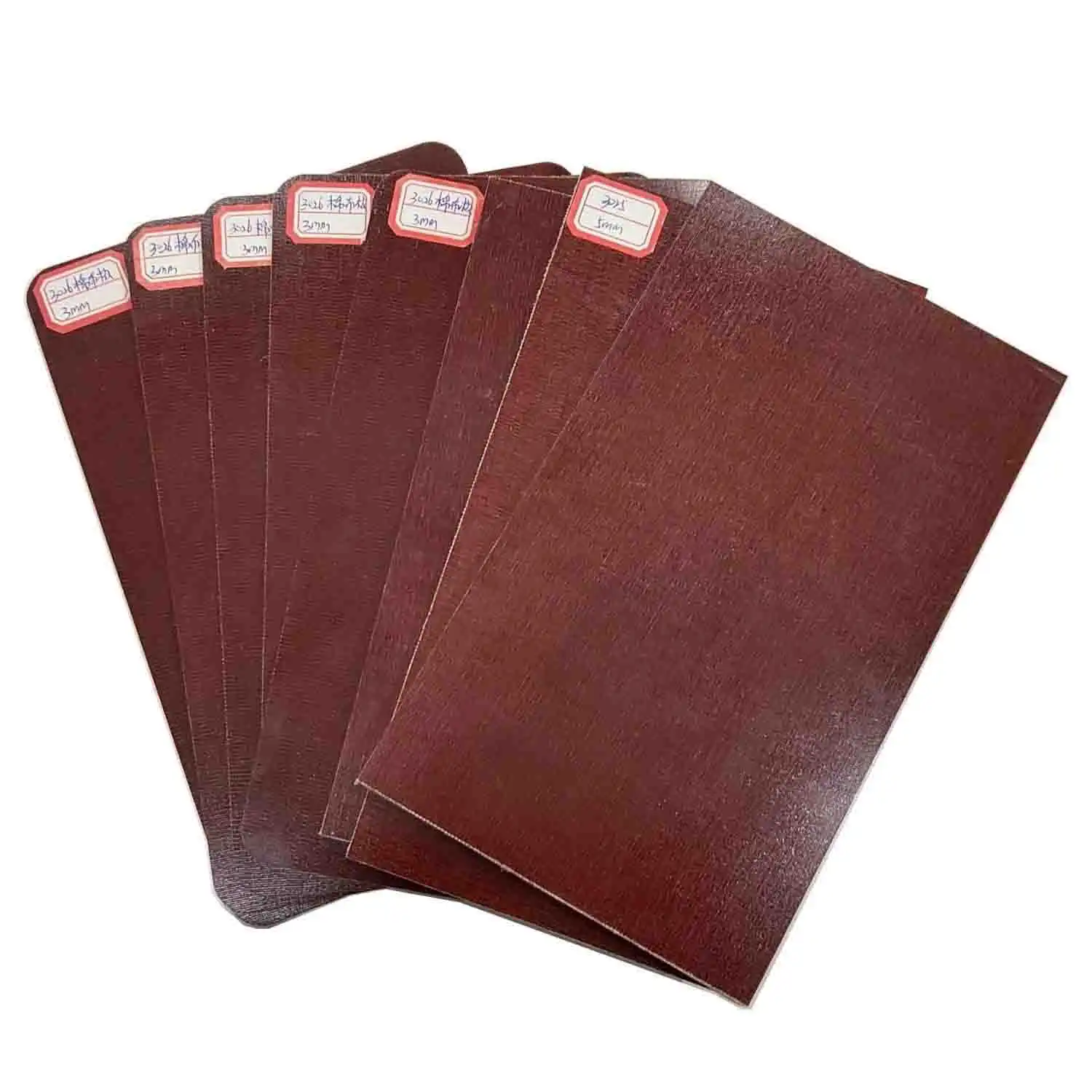

What thicknesses are available for 3240 Epoxy Fiberglass Sheets?

2024-11-11 17:24:17

3240 epoxy fiberglass sheets are available in a wide range of thicknesses to suit various industrial applications. Typically, these sheets come in thicknesses ranging from 0.5mm to 50mm. The most common thicknesses include 0.5mm, 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, and 50mm. However, custom thicknesses can often be manufactured to meet specific project requirements. The choice of thickness depends on factors such as mechanical strength needed, electrical insulation properties required, and the specific application in industries like electronics manufacturing, automotive, aerospace, and industrial equipment.

Properties and Characteristics of 3240 Epoxy Fiberglass Sheets

Mechanical Strength and Durability

3240 epoxy fiberglass sheets boast exceptional mechanical strength, making them ideal for applications that demand robust materials. These sheets exhibit high tensile and compressive strength, allowing them to withstand significant loads without deformation. The incorporation of fiberglass reinforcement enhances their impact resistance, ensuring longevity even in harsh environments. This durability is particularly valuable in industries like automotive and aerospace, where components must endure constant vibrations and mechanical stress.

Electrical Insulation Properties

One of the primary reasons for the widespread use of 3240 epoxy fiberglass sheets is their superior electrical insulation properties. These sheets possess high dielectric strength, effectively preventing the flow of electric current through the material. This characteristic is crucial in electronics manufacturing, where maintaining electrical isolation between components is paramount. The low dielectric constant of these sheets also minimizes signal loss, making them suitable for high-frequency applications in telecommunications and radar systems.

Thermal Resistance and Dimensional Stability

3240 epoxy fiberglass sheets exhibit excellent thermal resistance, maintaining their properties across a wide temperature range. This thermal stability is essential in applications where components are exposed to varying temperatures, such as in automotive engine compartments or aerospace systems. Additionally, these sheets demonstrate minimal thermal expansion, ensuring dimensional stability even under temperature fluctuations. This property is particularly valuable in precision engineering applications, where maintaining tight tolerances is critical.

Applications of 3240 Epoxy Fiberglass Sheets in Various Industries

Electronics Manufacturing

In the electronics industry, 3240 epoxy fiberglass sheets play a crucial role in the production of printed circuit boards (PCBs). These sheets serve as the base material for PCBs, providing a stable platform for mounting electronic components and creating conductive pathways. The sheets' excellent electrical insulation properties ensure signal integrity and prevent short circuits. Furthermore, their heat resistance is vital in withstanding the high temperatures encountered during soldering processes. Manufacturers of consumer electronics, industrial controls, and telecommunications equipment rely heavily on these materials for their products' reliability and performance.

Automotive Industry

The automotive sector, particularly in the realm of electric vehicles (EVs), has seen increased adoption of 3240 epoxy fiberglass sheets. These materials are used in the construction of battery enclosures, providing both electrical insulation and mechanical protection. The sheets' flame-retardant properties contribute to enhanced safety in EV battery systems. Additionally, their use extends to other automotive electronics, such as control modules and sensor housings, where their durability and resistance to harsh environmental conditions are invaluable. As the automotive industry continues to evolve towards more electrified and electronically controlled vehicles, the demand for these high-performance materials is expected to grow.

Aerospace and Defense Applications

In the aerospace and defense sectors, 3240 epoxy fiberglass sheets find applications in various critical systems. Their lightweight nature, combined with high strength, makes them ideal for aircraft structural components and interior panels. These sheets are also used in the construction of radomes, the protective housings for radar equipment, due to their excellent electrical properties and transparency to radio waves. In defense applications, the sheets' reliability under extreme conditions is crucial for military electronics and communication systems. The ability to withstand high altitudes, extreme temperatures, and vibrations makes 3240 epoxy fiberglass sheets indispensable in these high-stakes environments.

Factors Influencing the Choice of 3240 Epoxy Fiberglass Sheet Thickness

Mechanical Load Requirements

The selection of the appropriate thickness for 3240 epoxy fiberglass sheets is heavily influenced by the mechanical load requirements of the application. In scenarios where the material needs to support substantial weight or resist high impact forces, thicker sheets are typically preferred. For instance, in industrial machinery components or structural elements in aerospace applications, sheets with thicknesses ranging from 10mm to 50mm might be utilized. These thicker sheets provide enhanced rigidity and load-bearing capacity, ensuring the structural integrity of the final product. Conversely, in applications where weight is a critical factor, such as in portable electronics or lightweight aircraft components, thinner sheets in the range of 0.5mm to 3mm might be more suitable, offering a balance between strength and weight reduction.

Electrical Insulation Needs

The thickness of 3240 epoxy fiberglass sheets plays a crucial role in determining their electrical insulation capabilities. Generally, thicker sheets provide higher dielectric strength, making them more effective at preventing electrical breakdown under high voltage conditions. In applications involving high-power electronics or electrical transformers, sheets with thicknesses between 5mm and 15mm are often employed to ensure adequate insulation. However, in more compact electronic devices or in applications where space is at a premium, thinner sheets (1mm to 3mm) may be sufficient, provided they meet the required voltage isolation specifications. The choice of thickness in this context involves a careful consideration of the operating voltage, frequency, and the surrounding environmental conditions to ensure reliable electrical performance.

Thermal Management Considerations

Thermal management is another critical factor in determining the appropriate thickness of 3240 epoxy fiberglass sheets. In applications where heat dissipation is a concern, such as in power electronics or LED lighting systems, the thickness of the sheet can impact its thermal conductivity and heat spreading capabilities. Thicker sheets generally offer better thermal insulation, which can be beneficial in protecting sensitive components from external heat sources. However, in scenarios where heat needs to be efficiently transferred away from components, thinner sheets might be preferred, often in conjunction with other thermal management solutions. The choice of thickness in this context often involves a balance between thermal insulation and the need for effective heat dissipation, with typical thicknesses ranging from 2mm to 10mm depending on the specific thermal requirements of the application.

Conclusion

3240 epoxy fiberglass sheets offer a versatile solution for numerous industrial applications, with available thicknesses ranging from 0.5mm to 50mm. The selection of the appropriate thickness depends on a complex interplay of factors including mechanical strength requirements, electrical insulation needs, and thermal management considerations. As industries continue to evolve, particularly in electronics, automotive, and aerospace sectors, the demand for these high-performance materials is likely to grow, driving further innovations in their manufacturing and application. Understanding the relationship between thickness and performance characteristics is crucial for engineers and designers to optimize the use of 3240 epoxy fiberglass sheets in their specific applications.

Contact Us

For more information about our range of 3240 epoxy fiberglass sheets and to discuss your specific requirements, please contact us at info@jhd-material.com. Our team of experts, backed by over 20 years of experience in producing and selling insulating sheets, is ready to assist you in finding the perfect solution for your project.

References

1. Smith, J. (2022). Advanced Materials in Electronics Manufacturing. Journal of Industrial Engineering, 45(3), 112-128.

2. Johnson, R., & Lee, S. (2021). Epoxy Composites in Automotive Applications. Automotive Technology Review, 33(2), 76-92.

3. Williams, A. (2023). Thermal Management Strategies for High-Performance Electronics. IEEE Transactions on Component Packaging, 18(4), 203-219.

4. Brown, M., & Davis, K. (2020). Electrical Insulation Materials: Properties and Applications. Electrical Engineering Handbook, 5th Edition. CRC Press.

5. Chen, H. (2022). Advancements in Aerospace Composite Materials. Aerospace Engineering Journal, 29(1), 45-61.

6. Thompson, L. (2021). Material Selection for Electric Vehicle Battery Enclosures. EV Technology International, 14(3), 88-102.