What is the development trend of laminate sheet?

2022-09-05

After decades of development in my country, the species of laminate sheet have continued to increase such as FR4 sheet, 3240 epoxy sheet and Bakelite sheet, and the technical level has also been greatly improved, but there is still a large gap compared with developed countries. In order to improve the technical level of China's layers of pressure products and enhance the market competitiveness of products, we need to track the market dynamics of foreign layers of pressure products as the research direction of the next step of pressure products. A layer of pressure products that adapt to the technical requirements of developed countries to open up the international market.

1. Category

From the perspective of matrix resin, there are many types of China, such as epoxy resin, phenolic resin, methaclamine resin, diene ether resin, polyaline resin, and silicon resin. Polybate resin. However, from the perspective of increasing materials, there are only glass fabrics in my country without glass felt. The various opposite sex characteristics of the layer of the glass cloth enhancement plate are obvious, and the mechanical strength along the direction of the glass wire is very high, and the mechanical strength of other directions is poor, especially the mechanical strength of the vertical in the direction of the glass cloth. Such as, shear, drilling, attack wire) are prone to layering and other phenomena, and the glass felt layer pressure plate solves this problem. The enhanced material of the glass felt layer of the United States and Japan uses a thin felt of 100g/m2 ~ 150g/m2, while Europe uses 300g/m2 ~ 450g/m2 square cloth. There are 25mm long short cuts between the grid cloth. yarn. The latter's mechanical strength is more than 50%higher than the former.

And Table 2 Table 3.

In addition, Japan also produces a continuous thin plate with dry electrical aspects, thickness: 0.15mm ~ 0.30mm, and the thickness tolerance can be controlled within ± 5%.

2. Molding

At present, the production equipment of China's layer pressure plates use steam heating, open multi -layer oil compressor, and the main problem of the equipment is that the temperature fluctuates large, above ± 10 ° C, it is not easy to control when the production layer pressure plate, the flowing volume is extinguished, and the production of the layer of the layer pressure plate The thickness deviation is large. The developed country mainly uses oil -heated oil pressure machine to produce layers. Some manufacturers use vacuum pressure machines to solve these questions.

3. The performance of the laminate sheet

Chinese glass fiber -increased layer laminate sheets are increased by glass cloth, and layer pressure plates without glass felt. The following comparison is compared with similar products in Europe and the United States. Compared with the European and American layers, Chinese layers of laminate sheets are stored in the following problems:

a) Electricity is low. The main table is now: the flat layer is 30kV, while the European and American can reach more than 45kV. The insulation resistance after soaking is only 102MΩ ~ 103MΩ, while Europe and the United States can reach 105MΩ ~ 107MΩ.

b) The thickness deviation is large. For laminate sheet with thickness of 1mm ~ 3mm, Chinese thickness deviation is ± 15%~ ± 12%, while the deviation range of European and American laminate sheet is ± 10%~ ± 8%.

Properties of American Polyester Glass Felt Laminates

Performance | Unit | Typical value | ||||

68.100 | 68.090 | 68.030 | 68.340 | |||

Tensile Strength | MPa | 70 | 70 | 150 | 65 | |

Bending strength | 20℃ | MPa | 130 | 130 | 250 | 130 |

130℃ | MPa | 65 | 85 | 160 | 65 | |

Compression strength 10mm | Vertical layer | MPa | 250 | 250 | 400 | 210 |

Parallel layer | MPa | 150 | 150 | 190 | 150 | |

Shear strength 10mm | Vertical layer | MPa | 80 | 80 | 120 | 50 |

Parallel layer | MPa | 20 | 20 | 20 | 20 | |

Gap shock intensity 10mm Simplified bracket | MPa | 45 | 45 | 55 | 45 | |

Breakdown Voltage | KV | 40 | 40 | 40 | 40 | |

Dielectric constant 50Hz | 4.5 | 4.5 | 4.5 | 4.5 | ||

Dielectric loss 50 Hz | 0.05 | 0.05 | 0.05 | 0.05 | ||

Relative leakage electrical marks index | V | 600 | 600 | 600 | 600 | |

Density | g/cm2 | 1.77 | 1.75 | 1.70 | 1.75 | |

Water absorption | mg | 82 | 82 | 82 | 82 | |

Linear thermal inflation coefficient | 10^-6/K | 15 | 15 | 15 | 15 | |

Thermal conductivity | W/m.K | 0.40 | 0.40 | 0.40 | 0.40 | |

Flame retardant | HB | V-0 | HB | V-0 | ||

Low -temperature | GOOD | GOOD | MID | MID | ||

IEC model | UPGM1 | UPGM2 | UPGM3 | UPGM4 | ||

The main reason for the above problems are:

a) Fiberglass glass cloth. Most of the glass cloth used in my country is a product that directly uses unbrocessive -processed paraffin -type infiltration agents. Paraffects on the surface of glass fiber seriously affect the compatibility between the substrate resin and the glass cloth. The mechanical and electrical performance is low, especially the water along the glass wire is easy to pass. Therefore, the insulation resistance after soaking is particularly significant, which is reduced by 4 to 6.

b) Working equipment. The production equipment for domestic electrical engineering layer pressure plates (including the upper rubber and the oil compressor), while the European and American plastic machines use the plastic machine of the copper covering plate. The quality of the upper tape is good. Small oil compressors are heated by heat -conducting oil and small temperature fluctuations. Due to the good quality of the upper tape and the temperature of the oil compressor is uniform, the pressure technology of the layer pressure plate is stable, it is easy to control when the layer of the layer pressure plate, and the flow volume is small, so the thickness of the layer of the layer of the production is small.

1. Countermeasure

To participate in the competition in the national market, we still have a lot of work to do. Not only should we analyze the markets of developed countries, understand the standards and market conditions of developed countries, but also find out the reasons for the gap with developed countries, and find out how to solve these problems, thereby improving the technical level of my country's layer pressure plates, enhancing Product market competitiveness. We will start from the following aspects to improve the dispute between products.

Properties of European Polyester Glass Mat Laminates

Property | Unit | Typical value | Test Method | |

Density | g/cm3 | 1.85 | DIN53479 | |

Tensile Strength | MPa | 100 | DIN53455 | |

Bending strength | 23℃ | MPa | 200 | DIN53452 |

150℃ | 50 | |||

flexural modulus of elasticity | MPa | 10570 | DIN53457 | |

Impact strength | KJ/m2 | 100 | DIN53453 | |

Minimum compressive strength | Vertical layer | MPa | 300 | DIN53454 |

Parallel layer | 200 | |||

Bond strength | N | 2300 | DIN53457 | |

Insulation resistance Soak in water for 24 hours | Ω | 7.1*10^8 | DIN53482 | |

Parallel layer to withstand voltage 1min | Kv | 46 | DIN53481 | |

Vertical layer to withstand voltage 1min | Kv | 40 | DIN53481 | |

Dielectric constant 50 Hz | 5 | DIN53483 | ||

Dielectric loss | 50 Hz | 0.0092 | DIN53483 | |

1 MHz | 0.0372 | |||

Relative tracking index | CTI | 600 | IEC112 | |

Martin temperature | ℃ | 200 | DIN53462 | |

Arc resistant | s | 180 | ASTM D 495 | |

Linear expansion coefficient | 10^-6/K | 17 | DIN52328 | |

Thermal conductivity | W/m.K | 0.63 | DIN52612 | |

water absorption 4mm | mg | 60 | DIN53495 | |

a) Equipment

The vertical upper gel machine with a long -infrared heating device with a catalytic combustion device has a large investment at one time, but in the long run, it is beneficial. First, the temperature of the upper glue machine can reach 220 ° C, the temperature can be controlled in segmentation, and each moves within ± 1 ° C. The production efficiency of the upper tape is high and the quality is stable. Second, the glue content of the upper tape is evenly distributed. Third, the energy of the solvent after burning can be used, and the production cost is reduced. Fourth, as the environmental requirements are stepped up, the effective treatment of waste gas is the request of the social development, and the catalytic combustion is one of the reliability methods.

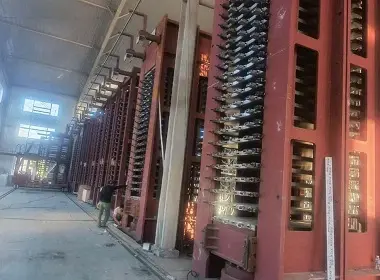

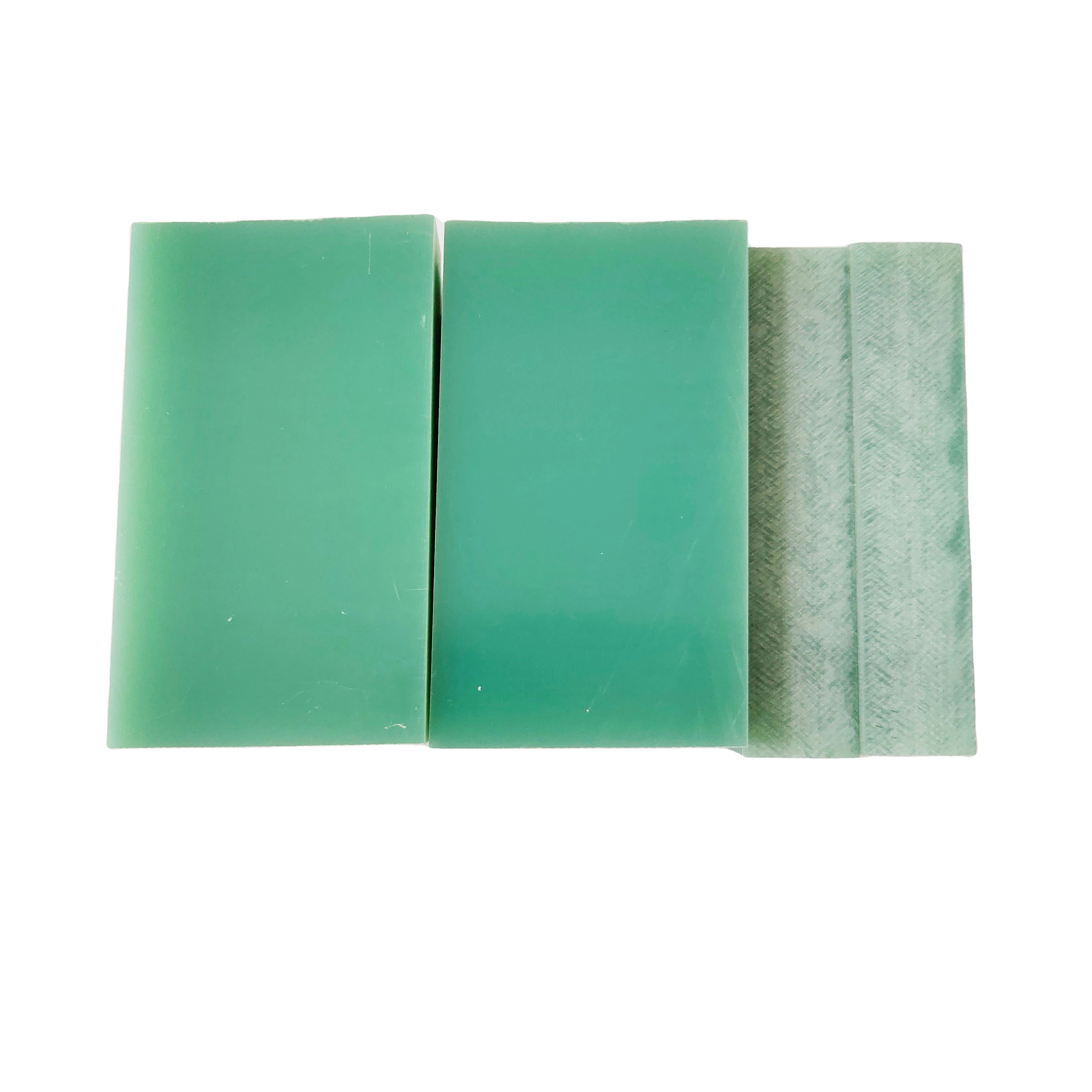

Our new factory Jinghong Electronic Technology Co., LTD has already equipped a vertical upper gel machine for making FR4 fiberglass sheet and so many top level vacuum pressure machines.

|

|

b) High pressure laminate sheet

First, choose the glass cloth treated by the interface as an enhanced material to enhance the compatibility of the substrate resin and glass cloth. Second, the substrate resin should not release low molecular objects during the reaction process. Third, under the premise of ensuring the liquidity of the upper tape, the volatilization of the upper tape should be as small as possible. Fourth, the production layer of the vacuum pressure machine is used.

c) Halogen -free flame retardant FR4 sheet

With the gradual improvement of environmental protection and safety requirements, developed countries are gradually prohibiting the use of halogen flame retardant materials. Study on structural materials for halogen -free flame -retardant structural materials are in the ascendant. These materials include structural materials such as transportation tools, buildings, etc.

d) Low cost, high -strength laminate sheet

The main reason for layer pressure plates in the construction industry is the high cost. As a building material, it not only requires high strength, but also has low cost. Therefore, low -cost and high -intensity pressure plates are one of the directions for development.