What is laminating epoxy used for?

2024-09-06 17:12:40

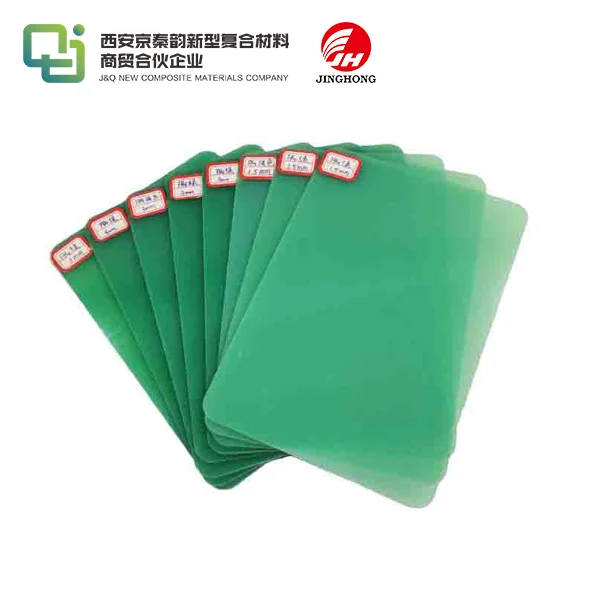

Epoxy laminate sheets have become indispensable in various industries due to their exceptional properties and versatile applications. These robust materials offer a unique combination of strength, durability, and electrical insulation, making them ideal for a wide range of uses. Let's delve into the world of laminating epoxy and explore its myriad applications.

The Fundamentals of Epoxy Laminate Sheets

Composition and Manufacturing Process

Epoxy laminate sheets are composite materials created by impregnating reinforcement fabrics, such as fiberglass or carbon fiber, with epoxy resin. This process involves carefully layering the fabric and resin, then subjecting the composite to heat and pressure. The result is a high-performance material that boasts superior mechanical and electrical properties.

Key Properties of Epoxy Laminates

Epoxy laminate sheets exhibit a remarkable set of characteristics that make them highly sought-after in various applications:

- Exceptional Strength-to-Weight Ratio: These materials offer impressive strength while remaining lightweight, making them ideal for aerospace and automotive industries.

- Superior Electrical Insulation: Epoxy laminates provide excellent electrical insulation properties, crucial for electronic and electrical applications.

- Chemical Resistance: These sheets demonstrate strong resistance to various chemicals, oils, and solvents, enhancing their durability in harsh environments.

Comparing Epoxy Laminates to Other Materials

When compared to traditional materials like metal or wood, epoxy laminate sheets offer several advantages:

- Corrosion Resistance: Unlike metals, epoxy laminates do not corrode, extending the lifespan of products and reducing maintenance costs.

- Design Flexibility: The moldable nature of epoxy laminates allows for complex shapes and designs that may be challenging with other materials.

- Thermal Stability: Epoxy laminates maintain their properties across a wide temperature range, outperforming many conventional materials in extreme conditions.

Industrial Applications of Epoxy Laminate Sheets

Electronics and Electrical Industry

Printed Circuit Boards (PCBs): One of the most prevalent uses of epoxy laminate sheets is in the production of printed circuit boards. The excellent electrical insulation properties and dimensional stability of these materials make them ideal substrates for PCBs. They provide a reliable foundation for electronic components and conductive pathways, ensuring the integrity and performance of electronic devices.

Insulation Components: Epoxy laminate sheets are extensively used to create various insulation components in electrical systems. These include:

- Switchgear Insulation: High-voltage switchgear relies on epoxy laminates for their excellent dielectric strength and arc resistance.

- Transformer Insulation: The sheets are used to insulate transformer windings, enhancing the efficiency and safety of power distribution systems.

- Motor Insulation: Epoxy laminates provide crucial insulation in electric motors, contributing to their longevity and performance.

Aerospace and Automotive Industries

Structural Components: The aerospace and automotive sectors leverage the high strength-to-weight ratio of epoxy laminate sheets to create lightweight yet robust structural components. These applications include:

- Aircraft Interiors: Epoxy laminates are used in cabin panels, overhead bins, and flooring, reducing overall aircraft weight without compromising strength.

- Automotive Body Panels: These materials are increasingly being used in vehicle body panels to improve fuel efficiency and reduce emissions.

- Racing Car Components: Formula 1 and other high-performance racing cars utilize epoxy laminates in various parts to achieve optimal weight distribution and aerodynamics.

Protective Coatings: Epoxy laminate sheets also find applications as protective coatings in both aerospace and automotive industries:

- Aircraft Radomes: These dome-shaped structures that protect radar equipment are often made from epoxy laminates due to their transparency to radio waves and durability.

- Automotive Underbody Shields: Epoxy laminates are used to create protective shields that guard against road debris and environmental factors.

Marine and Construction Applications

Boat Building and Repair: The marine industry extensively uses epoxy laminate sheets for various applications:

- Hull Construction: Epoxy laminates are used to create strong, lightweight hulls that resist water absorption and marine growth.

- Deck Structures: These materials are ideal for constructing deck components that can withstand harsh marine environments.

- Repair and Maintenance: Epoxy laminates are used in repair kits for boats and other marine vessels, offering durable and waterproof solutions.

Construction and Infrastructure: In the construction industry, epoxy laminate sheets have found numerous applications due to their durability and versatility:

- Bridge Reinforcement: These materials are used to strengthen and repair aging bridge structures, extending their lifespan and improving safety.

- Corrosion-Resistant Piping: Epoxy laminates are utilized in creating pipes and tanks that can withstand corrosive chemicals and harsh environments.

- Architectural Panels: The aesthetic appeal and durability of epoxy laminates make them suitable for decorative architectural panels in both interior and exterior applications.

Emerging Applications and Future Prospects

Renewable Energy Sector

Wind Turbine Blades: The renewable energy sector, particularly wind energy, has embraced epoxy laminate sheets for their unique properties:

- Blade Construction: Epoxy laminates are crucial in manufacturing wind turbine blades, providing the necessary strength and flexibility to withstand high winds and extreme weather conditions.

- Nacelle Components: These materials are also used in various components of the nacelle, the housing that contains the generator and gearbox.

- Lightning Protection: Epoxy laminates with conductive additives are used to create lightning protection systems for wind turbines.

Solar Panel Encapsulation: In the solar energy industry, epoxy laminate sheets play a vital role:

- Panel Backing: These materials are used as backing sheets for solar panels, providing protection against moisture and environmental factors.

- Encapsulation Materials: Epoxy laminates are used to encapsulate solar cells, ensuring their longevity and efficiency.

- Mounting Structures: The lightweight and durable nature of these materials makes them ideal for creating solar panel mounting structures.

Medical and Healthcare Applications

Prosthetics and Orthotics: The medical field has found innovative uses for epoxy laminate sheets:

- Prosthetic Limbs: These materials are used to create lightweight, durable prosthetic limbs that offer improved comfort and functionality for patients.

- Orthotic Devices: Epoxy laminates are utilized in manufacturing custom orthotic devices, providing necessary support while remaining lightweight.

- Medical Equipment Housings: The electrical insulation properties of these materials make them suitable for creating housings for various medical devices.

Advancements in Epoxy Laminate Technology

Nano-Enhanced Epoxy Laminates: Research in nanotechnology has led to the development of nano-enhanced epoxy laminates:

- Improved Strength: The addition of nanoparticles can significantly enhance the mechanical properties of epoxy laminates.

- Enhanced Thermal Conductivity: Certain nanoparticles can improve the thermal conductivity of these materials, opening up new applications in heat management.

- Self-Healing Properties: Ongoing research is exploring the potential of self-healing epoxy laminates, which could revolutionize maintenance in various industries.

Biodegradable Epoxy Laminates: As environmental concerns grow, there's increasing focus on developing more sustainable epoxy laminates:

- Bio-Based Resins: Researchers are exploring the use of plant-based resins to create more environmentally friendly epoxy laminates.

- Recyclable Composites: Efforts are underway to develop epoxy laminates that can be more easily recycled at the end of their lifecycle.

- Reduced Environmental Impact: These advancements aim to minimize the carbon footprint of epoxy laminate production and disposal.

Conclusion

In conclusion, epoxy laminate sheets have proven to be versatile materials with a wide range of applications across various industries. From electronics to aerospace, construction to renewable energy, these materials continue to play a crucial role in technological advancements and innovation. As research progresses, we can expect to see even more exciting applications and improvements in epoxy laminate technology, further solidifying its position as a key material in modern manufacturing and engineering.

For more information about our high-quality epoxy laminate sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.

References

Johnson, A. R. (2019). Advanced Composites in the Aerospace Industry: Applications and Innovations.

Smith, L. K. (2020). Epoxy Resins: Properties, Applications, and Future Trends in Manufacturing.

Chen, X. et al. (2018). Nano-Enhanced Epoxy Composites: Advancements in Mechanical and Thermal Properties.

Thompson, R. M. (2021). Sustainable Composites: The Future of Epoxy Laminates in Green Manufacturing.

Patel, S. K. (2019). Electrical Insulation Materials: A Comprehensive Guide to Modern Applications.

Rodriguez, E. L. (2020). Marine Composites: Innovations in Boat Building and Repair Techniques.

拷贝.webp)