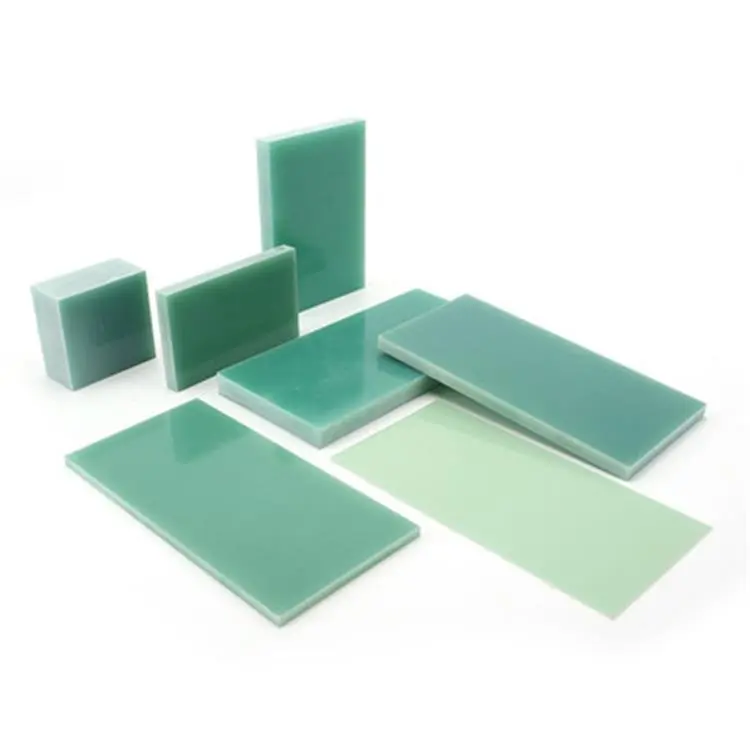

What is G10 FR4 sheet?

2024-08-09 13:50:20

If you're involved in electronics manufacturing, circuit board production, or any industry that requires high-performance insulating materials, you've likely come across G10 FR4 sheet. This versatile material has become a staple in various applications due to its exceptional properties. In this blog post, we'll dive deep into the world of G10 FR4 sheet, exploring its composition, characteristics, and applications.

Understanding the Composition of G10 FR4 Sheet

G10 FR4 sheets are widely recognized for their robust performance and versatility in various applications, owing to their unique composition and manufacturing process. To fully appreciate the properties and advantages of G10 FR4 sheets, it's essential to understand their composition in detail, composition of G10 FR4 sheet as follow:

Epoxy Resin

At the heart of G10 FR4 sheets is epoxy resin, a thermosetting polymer known for its excellent mechanical properties and resistance to environmental degradation. The resin acts as the matrix material that binds the glass fibers together, providing structural integrity and durability. Epoxy resins are chosen for their strong adhesive qualities, low shrinkage, and high resistance to moisture, chemicals, and heat. This makes them ideal for applications where stability and reliability are crucial.

Woven Glass Fiber

The reinforcement material in G10 FR4 sheets is woven glass fiber, which consists of fine glass filaments arranged in a cross-weave pattern. This woven structure enhances the material's mechanical strength and flexibility. Glass fibers are known for their high tensile strength, rigidity, and resistance to various environmental factors. They also contribute to the electrical insulating properties of G10 FR4 sheets, making them suitable for use in electrical and electronic applications.

Flame Retardant Properties

The "FR4" designation indicates that the material has flame retardant properties. This means that G10 FR4 sheets are treated or manufactured to resist ignition and prevent the spread of flames. This flame resistance is achieved through the careful selection and formulation of the epoxy resin and glass fibers. The FR4 grade ensures that the material meets specific fire safety standards, making it a preferred choice for applications where fire resistance is a key requirement.

Key Characteristics and Benefits of G10 FR4 Sheet

G10 FR4 sheet boasts an impressive array of properties that make it a popular choice in many industries. Some of the key characteristics include:

Excellent Electrical Insulation

The high dielectric strength of G10 FR4 makes it an outstanding material for preventing electrical currents from unintended paths. This characteristic is crucial in electronic applications where reliable insulation is essential to prevent short circuits and ensure safety. Its low electrical conductivity ensures minimal energy loss and reliable performance in electronic devices.

Flame Retardant

The "FR4" designation indicates that the material is treated to resist ignition and prevent the spread of flames. This flame resistance is a critical safety feature in many applications, particularly in electrical and electronic environments where overheating or electrical faults could pose a fire risk. By incorporating flame retardant properties, G10 FR4 helps enhance safety and compliance with fire safety standards, making it suitable for use in high-risk areas where fire resistance is a priority.

Dimensional Stability

G10 FR4 sheets exhibit excellent dimensional stability, meaning they maintain their shape and size despite fluctuations in environmental conditions. This property is essential for applications that experience temperature changes, mechanical stress, or exposure to various elements. The material’s ability to resist warping, shrinking, or expanding ensures consistent performance and accuracy in applications such as mechanical components, structural parts, and electronic enclosures. Dimensional stability also contributes to the longevity of products made with G10 FR4, reducing the need for frequent replacements or adjustments.

Low Moisture Absorption

G10 FR4 sheets are engineered to have low moisture absorption, which helps maintain their electrical and mechanical properties even in humid or wet environments. This characteristic is particularly beneficial in applications where the material might be exposed to moisture. Low moisture absorption prevents degradation of the material's strength, insulation, and overall performance, ensuring reliable operation and longevity in challenging conditions.

High Mechanical Strength

The material offers impressive tensile and flexural strength, making it suitable for applications requiring robust structural support. This high mechanical strength ensures that G10 FR4 can withstand considerable stress and pressure without deformation or failure.

Chemical Resistance

G10 FR4 sheets are highly resistant to a wide range of chemicals, including oils, solvents, and acids. This chemical resistance ensures that the material remains stable and effective even when exposed to harsh substances. This property is crucial for applications in chemical processing, industrial environments, and areas where contact with aggressive chemicals is common. The ability to resist chemical corrosion contributes to the material’s durability and extends its service life.

Applications and Uses of G10 FR4 Sheet

The versatility of G10 FR4 sheet has led to its widespread use across multiple industries. Some common applications include:

Printed Circuit Boards (PCBs)

In PCB manufacturing, G10 FR4 provides a stable, durable base that supports the electronic components and conductive pathways essential for circuit functionality. The material’s high dielectric strength ensures reliable electrical insulation between the board’s layers and components. Its dimensional stability maintains the integrity of the circuit layout, while its flame-retardant properties contribute to the safety and reliability of electronic devices.

Electrical Insulation

The excellent dielectric properties of G10 FR4 sheets make them ideal for various electrical insulation applications. G10 FR4 is used in insulators, electrical enclosures, and spacers to protect sensitive electronic components and ensure stable electrical performance. Its ability to withstand high voltages and resist moisture further enhances its effectiveness in demanding electrical environments.

Aerospace and Defense

In the aerospace and defense sectors, they are used in various components such as aircraft panels, radomes, and structural parts that require both high mechanical strength and dimensional stability. G10 FR4’s use in military equipment also leverages its durability and resistance to chemicals and physical stress.

Industrial Equipment

G10 FR4’s durability and chemical resistance make it an excellent choice for industrial equipment and machinery. The material’s ability to resist corrosion and chemical exposure ensures that it maintains its performance and integrity over time. Its mechanical strength allows it to handle significant loads and stresses, making it suitable for various industrial applications where reliability and long-term performance are essential.

Automotive

In the automotive industry, G10 FR4 sheets are used in various electronic and electrical systems. The material’s electrical insulation properties are critical for automotive electronics, such as sensors, control units, and connectors. G10 FR4 is also used in components that require high strength and dimensional stability. Its resistance to temperature fluctuations and environmental conditions ensures reliable performance in automotive applications.

Medical Devices

In medical technology, the material’s ability to provide consistent electrical insulation is crucial for devices that operate in sensitive environments. G10 FR4 is used in components such as diagnostic equipment, surgical instruments, and electronic medical devices where reliability and safety are critical. Its chemical resistance also contributes to maintaining the integrity of medical devices in sterilization and harsh cleaning processes.

Conclusion

G10 FR4 sheet stands out as a highly versatile and reliable material with a broad range of applications across multiple industries. By understanding the composition and benefits of G10 FR4 sheet, professionals can better leverage its attributes to enhance the performance and safety of their products. Whether for manufacturing PCBs, insulating electrical components, or constructing durable industrial parts, G10 FR4 continues to be a key material in achieving high-quality and reliable results in demanding environments.

To learn more about G10 FR4 sheet or to discuss your insulating material needs, don't hesitate to reach out to us at info@jhd-material.com. We're committed to providing top-quality products and excellent service to meet your requirements.

References

1. "G10/FR4 Epoxy Laminates and Prepregs."

2. "FR-4 Epoxy Fiberglass Composite: An Overview."

3. "Understanding G10 and FR4 Composite Materials."

4. "Properties and Applications of FR4 Laminates."

5. "G10 FR4 Epoxy Sheet: Properties and Uses."