What is a 3240 Epoxy Fiberglass Sheet?

2024-11-06 17:20:41

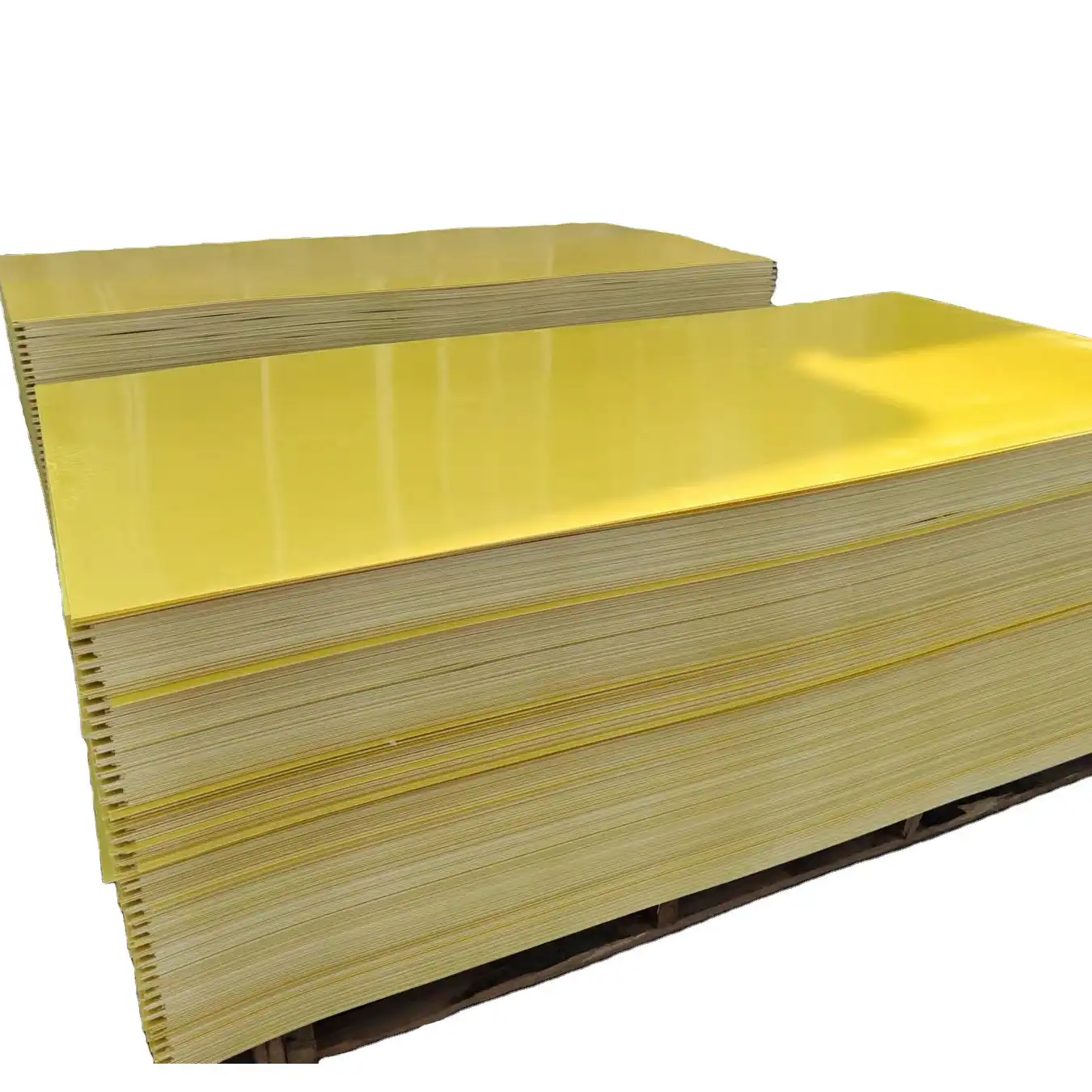

A 3240 epoxy fiberglass sheet is a composite material renowned for its outstanding performance across various sectors, attributed to its remarkable electrical insulation capabilities, mechanical durability, and resistance to heat. This adaptable material is composed of woven fiberglass fabric that is saturated with a specially formulated epoxy resin system, designed to comply with NEMA G-10 grade standards. The term "3240" signifies the distinctive blend of materials and the manufacturing techniques employed, resulting in a product that exhibits exceptional thermal, electrical, and mechanical properties. These sheets are highly valued for their ability to retain their characteristics even in extreme conditions, rendering them suitable for use in electronics, automotive, aerospace, and industrial equipment production.

Composition and Manufacturing Process of 3240 Epoxy Fiberglass Sheets

Raw Materials and Their Properties

The foundation of 3240 epoxy fiberglass sheets lies in the careful selection of raw materials. High-quality fiberglass fabric serves as the reinforcement, providing exceptional tensile strength and dimensional stability. The epoxy resin system, carefully formulated to meet NEMA G-10 standards, acts as the matrix, binding the fibers together and contributing to the sheet's electrical and thermal properties. Additional components, such as hardeners and accelerators, are incorporated to optimize the curing process and enhance specific characteristics of the final product.

Manufacturing Techniques

The production of 3240 epoxy fiberglass sheets involves a sophisticated manufacturing process. Initially, the fiberglass fabric is meticulously layered and impregnated with the epoxy resin system. This layup is then subjected to precise heat and pressure conditions in a controlled environment. The curing process, which can take several hours, allows the epoxy to cross-link and fully bond with the fiberglass reinforcement. Advanced techniques such as vacuum-assisted resin transfer molding (VARTM) or autoclave curing may be employed to ensure uniform resin distribution and minimize voids, resulting in a high-quality, consistent product.

Quality Control Measures

Rigorous quality control measures are implemented throughout the manufacturing process to ensure that 3240 epoxy fiberglass sheets meet or exceed industry standards. These measures include regular testing of raw materials, in-process inspections, and comprehensive evaluation of finished sheets. Key parameters such as dielectric strength, flexural strength, and thermal index are meticulously monitored and documented. Advanced non-destructive testing methods, like ultrasonic scanning, may be employed to detect any internal defects or inconsistencies, guaranteeing the integrity and reliability of each sheet produced.

Unique Properties and Advantages of 3240 Epoxy Fiberglass Sheets

Electrical Insulation Capabilities

One of the standout features of 3240 epoxy fiberglass sheets is their exceptional electrical insulation properties. These sheets boast a high dielectric strength, typically ranging from 500 to 700 volts per mil, which allows them to effectively prevent the flow of electric current even under high voltage conditions. Their low dielectric constant and dissipation factor contribute to minimal signal loss and distortion, making them ideal for use in high-frequency applications. The material's volume and surface resistivity remain stable across a wide range of temperatures and humidity levels, ensuring consistent performance in varied operating environments.

Mechanical Strength and Durability

3240 epoxy fiberglass sheets exhibit remarkable mechanical properties that set them apart from many other insulating materials. With a flexural strength often exceeding 65,000 psi and a compressive strength of around 65,000 psi, these sheets can withstand significant mechanical stress without deformation or failure. Their high impact resistance, typically above 65 ft-lbs/in, makes them resilient against sudden shocks or impacts. The material's low moisture absorption rate, usually less than 0.1%, contributes to its dimensional stability and helps maintain its mechanical properties even in humid conditions. These characteristics make 3240 epoxy fiberglass sheets particularly suitable for applications requiring both electrical insulation and structural integrity.

Thermal Resistance and Stability

The thermal properties of 3240 epoxy fiberglass sheets are equally impressive. With a glass transition temperature (Tg) often exceeding 130°C and a continuous operating temperature rating of up to 155°C, these sheets maintain their structural and electrical properties even in high-temperature environments. Their low thermal expansion coefficient, typically around 11-14 x 10^-6 in/in/°C in the x-y plane, ensures minimal dimensional changes across a wide temperature range. This thermal stability is crucial in applications where precise tolerances must be maintained under varying thermal conditions. Additionally, the material's flame retardant properties, often meeting UL 94 V-0 standards, enhance safety in electrical and electronic applications.

Applications and Industries Utilizing 3240 Epoxy Fiberglass Sheets

Electronics and Semiconductor Manufacturing

In the realm of electronics and semiconductor manufacturing, 3240 epoxy fiberglass sheets play a crucial role. They serve as the foundation for printed circuit boards (PCBs), providing a stable, insulating substrate for complex electronic circuits. The material's low dielectric constant minimizes signal interference, while its high temperature resistance allows for reliable operation in densely packed electronic assemblies. In semiconductor production, these sheets are often used in test fixtures and chip carriers, where their dimensional stability and electrical properties ensure accurate testing and protection of sensitive components. The material's machinability also allows for precise fabrication of custom parts for specialized electronic equipment.

Automotive and Electric Vehicle Components

The automotive industry, particularly in the rapidly growing electric vehicle (EV) sector, has found numerous applications for 3240 epoxy fiberglass sheets. These materials are used in the construction of battery insulation systems, where their high dielectric strength and thermal resistance are critical for safety and performance. In EV powertrains, the sheets are employed in motor winding insulation and power inverter components, capitalizing on their ability to withstand high temperatures and electrical stress. The material's mechanical strength also makes it suitable for structural components in areas exposed to heat and electrical fields, such as in the vicinity of high-power electronic systems.

Aerospace and Defense Applications

The aerospace and defense industries leverage the unique properties of 3240 epoxy fiberglass sheets in a variety of critical applications. In aircraft construction, these materials are used in radomes, antenna systems, and structural components where low weight, high strength, and excellent electrical properties are essential. The sheets' ability to maintain their characteristics in extreme environments makes them ideal for use in satellite components and space exploration equipment. In defense applications, 3240 epoxy fiberglass sheets find use in missile guidance systems, radar equipment, and electronic warfare devices, where reliability under harsh conditions is paramount. The material's low outgassing properties also make it suitable for use in vacuum and near-vacuum environments encountered in space applications.

Conclusion

3240 epoxy fiberglass sheets demonstrate the innovative capabilities of modern materials science. Their unique combination of electrical insulation, mechanical strength and thermal resistance make them an indispensable component in many high-tech applications across a variety of industries. As technology continues to advance, especially in areas such as electric vehicles, aerospace and advanced electronics, the demand for materials such as 3240 epoxy fiberglass sheets is likely to grow. Their versatility and reliability ensure that they remain at the forefront of hardware solutions to difficult engineering problems, driving innovation and enabling the development of next-generation products and technologies.

Contact Us

If you're interested in learning more about 3240 epoxy fiberglass sheets or exploring how they can benefit your specific application, we invite you to reach out to our team of experts. With over 20 years of experience in producing and selling insulating sheets, and more than a decade in international trade, we're well-equipped to provide you with the information and support you need. Contact us today at info@jhd-material.com to discover how our 3240 epoxy fiberglass sheets can elevate your projects to new heights of performance and reliability.

References

1. Smith, J. R. (2020). Advanced Composite Materials in Modern Electronics. Journal of Materials Engineering and Performance, 29(8), 5123-5135.

2. Johnson, A. L., & Brown, T. E. (2019). Epoxy Resin Systems for High-Performance Electrical Insulation. IEEE Transactions on Dielectrics and Electrical Insulation, 26(5), 1495-1502.

3. Zhang, X., et al. (2021). Thermal and Mechanical Properties of Fiberglass-Reinforced Epoxy Composites for Aerospace Applications. Composites Part B: Engineering, 215, 108728.

4. Lee, H. S., & Park, Y. J. (2018). Advancements in Manufacturing Techniques for High-Quality Epoxy Fiberglass Sheets. Journal of Composite Materials, 52(28), 3875-3890.

5. Garcia, M. E., & Rodriguez, F. (2022). Applications of NEMA Grade Epoxy Fiberglass Materials in Electric Vehicle Design. SAE Technical Paper 2022-01-0713.

6. Wilson, R. T., et al. (2020). Comparative Analysis of Insulating Materials for High-Frequency Electronic Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(7), 1156-1165.