What are the temperature resistance properties of Epoxy Sheets for Battery Packs?

2024-07-03 16:31:58

As a professional in the field of battery pack technology, we recognize the critical role that temperature resistance plays in ensuring the efficiency, longevity, and safety of battery systems. In this comprehensive article, I will delve into the temperature resistance properties of Epoxy Resin Sheets specifically designed for battery packs, shedding light on their composition, testing methods, practical applications, and more.

Understanding the Importance of Temperature Resistance in Battery Pack Applications

In battery pack applications, temperature obstruction assumes an essential part in guaranteeing the well-being, execution, and life span of the battery framework. Batteries are delicate to temperature vacillations, and keeping an ideal working temperature range is fundamental for their productivity and unwavering quality.

High temperatures, first and foremost, can speed up substance responses inside the battery cells, prompting expanded self-release rates, diminished limit, and sped-up corruption of cathode materials. This can bring about diminished battery life expectancy and execution over the long run. Then again, low temperatures can cause diminished particle portability and expanded interior obstruction, prompting decreased power results and proficiency, particularly in chilly climate conditions.

Additionally, outrageous temperatures can likewise present dangers, like warm out of control, where the battery encounters uncontrolled temperature climb, possibly prompting fire or blast. Subsequently, battery pack plans should consolidate the temperature of the executive's frameworks, like warm protection, cooling/warming components, and temperature sensors, to keep up with ideal working circumstances and forestall warm control occasions.

Besides, in applications where batteries are exposed to high encompassing temperatures or working in unforgiving conditions, for example, auto, aviation, or energy stockpiling frameworks, guaranteeing temperature opposition turns out to be considerably more basic. Battery pack parts, including packaging materials, protection, and warm administration frameworks, should be fit for enduring raised temperatures without compromising execution or security.

Exploring the Composition of Epoxy Sheets for Battery Packs

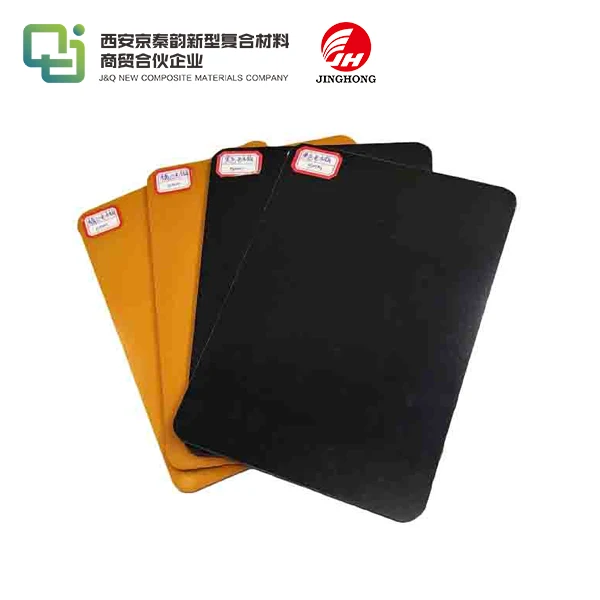

Epoxy Resin Sheets are commonly employed in battery pack assembly due to their excellent thermal and electrical insulation properties. These sheets act as insulating barriers between battery cells, protecting them from external heat sources and maintaining optimal operating temperatures. However, not all epoxy sheets offer the same level of temperature resistance, making it essential to understand their composition and performance characteristics.

The full sulfur hexafluoride circuit breaker is a prime example of a component that requires exceptional temperature resistance. As a crucial element in high-voltage electrical systems, circuit breakers must withstand extreme temperatures without compromising their functionality. Epoxy sheets used in the insulation of circuit breakers undergo rigorous testing to ensure they meet stringent temperature resistance standards.

Factors Influencing Temperature Resistance in Epoxy Sheets

The temperature resistance of Epoxy Sheets for Battery Packs is influenced by various factors, including the type of epoxy resin used, filler materials, curing process, and thickness of the sheet. Epoxy resins with high glass transition temperatures (Tg) exhibit better temperature resistance, as they remain stable at elevated temperatures commonly encountered in battery pack applications.

Filler materials, such as silica or alumina, are often incorporated into epoxy formulations to enhance thermal conductivity and improve temperature resistance. These fillers help dissipate heat more efficiently, preventing localized hotspots that can degrade the performance of battery cells.

The curing process also plays a crucial role in determining the temperature resistance of epoxy sheets. Proper curing ensures the formation of a dense, cross-linked polymer network, which enhances the mechanical strength and thermal stability of the material. Additionally, controlling the curing temperature and duration is essential to achieving uniform properties across the epoxy sheet.

Testing and Evaluation Methods for Temperature Resistance

Testing and assessing temperature obstruction includes a few strategies to guarantee sturdiness and usefulness under changing warm circumstances. Warm cycling subjects materials or parts to rehash temperature variances, copying certifiable utilization to survey long haul execution. Warm shock testing opens them to quick temperature changes to measure protection from abrupt movements.

Differential filtering calorimetry (DSC) and thermogravimetric investigation (TGA) examine warm properties like liquefying focuses and steadiness, offering experiences in material conduct under heat. Infrared thermography outwardly maps temperature dissemination, distinguishing areas of interest and warm shortcomings. Sped-up maturing tests mimic delayed openness to raised temperatures, anticipating long-haul strength.

These techniques on the whole give a thorough comprehension of a material or part's capacity to endure temperature varieties, directing item improvement for different applications, including battery packs, where temperature soundness is basic for security and execution.

Practical Applications and Considerations for Epoxy Sheets in Battery Packs

Practical applications of Epoxy Sheets for Battery Packs in battery packs extend beyond insulation and thermal management. These versatile materials can also serve as structural components, adhesives, and encapsulants, further enhancing the reliability and performance of battery systems. Whether used in automotive, aerospace, or stationary energy storage applications, epoxy sheets play a crucial role in ensuring the long-term success of battery pack designs.

Contact Us

In conclusion, understanding the temperature resistance properties of Epoxy Resin Sheets is essential for designing reliable and efficient battery packs. By selecting high-quality materials with proven performance characteristics, manufacturers can enhance the durability, safety, and performance of their battery systems. As a professional manufacturing supplier specializing in epoxy materials for battery pack applications, we are committed to providing our customers with innovative solutions that meet their specific needs. Contact us today to learn more about our GMP factory, large inventory, complete certificates, OEM support, fast delivery, and comprehensive testing capabilities. Partner with us to elevate your battery pack designs and attract global buyers seeking superior quality and performance. Reach out to us at info@jhd-material.com to discuss how we can support your projects and drive success in the rapidly evolving battery industry.

References:

- "Epoxy Resins Handbook" by Phillip H. Francis

- "Battery Management Systems" by H.J. Bergveld

- "Thermal Management of Electric Vehicle Battery Systems" by Ahmad Pesaran

- "Electrical Insulation for Rotating Machines" by Greg Stone