What are the properties of G10 FR4?

2024-08-12 14:36:37

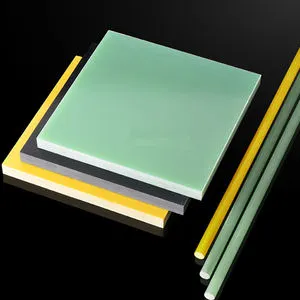

When it comes to high-performance insulating materials, G10 FR4 sheet stands out as a versatile and reliable option. Whether you're in the electronics industry, aerospace sector, or any field requiring robust insulation, understanding the properties of G10 FR4 can help you make informed decisions for your projects. Let's dive into the characteristics that make this material so popular and explore its various applications.

What Is the Composition of G10 FR4 Sheet?

G10 FR4 is a type of glass-reinforced epoxy laminate sheet that combines strength with excellent electrical insulation properties. The "G10" designation refers to its glass fabric base, while "FR4" stands for "Flame Retardant," indicating its ability to resist combustion. This composite material is made by impregnating layers of woven fiberglass cloth with epoxy resin and then curing it under heat and pressure. G10 FR4 is a durable, high-strength material that offers a unique combination of mechanical, electrical, and thermal properties. G10 FR4 sheet is known for its:

High Mechanical Strength

The woven fiberglass base provides exceptional tensile and flexural strength, making G10 FR4 suitable for structural applications in high-stress environments.

Excellent Electrical Insulation

The epoxy resin matrix ensures that the material is a superb electrical insulator, crucial for applications in electronics, particularly in printed circuit boards (PCBs).

Low Moisture Absorption

The low moisture absorption characteristic helps maintain the material’s integrity and performance in humid or wet conditions.

Good Chemical Resistance

G10 FR4 is resistant to a wide range of chemicals, making it suitable for use in harsh industrial environments where exposure to corrosive substances is common.

Dimensional Stability

G10 FR4 is resistant to a wide range of chemicals, making it suitable for use in harsh industrial environments where exposure to corrosive substances is common.

These properties make G10 FR4 an ideal choice for various applications, from printed circuit boards (PCBs) to structural components in high-stress environments.

What Are the Key Mechanical and Electrical Properties of G10 FR4?

The G10 FR4 sheet is renowned for its exceptional mechanical and electrical properties, which make it a versatile and reliable material across various industries. Its unique composition endows it with characteristics that are highly valued in demanding applications. Let's delve deeper into some of these key mechanical and electrical properties to understand why G10 FR4 is so widely used.

Mechanical Properties

- High Flexural Strength: G10 FR4 exhibits remarkable flexural strength, enabling it to withstand significant bending forces without breaking. This property is particularly important in applications where the material must endure mechanical stress and deformation. Whether in structural components or protective casings, the high flexural strength ensures durability and long-term performance.

- Excellent Tensile Strength: material's ability to resist pulling or stretching forces. G10 FR4's high tensile strength makes it suitable for load-bearing applications where robustness and reliability are critical. It can handle substantial loads without experiencing failure, making it ideal for mechanical and structural uses.

- Low Thermal Expansion: Maintaining dimensional stability across a wide temperature range is crucial for precision applications. G10 FR4 has a low coefficient of thermal expansion, meaning it does not expand or contract significantly with temperature changes. This stability ensures that components made from G10 FR4 retain their accuracy and fit, even in environments subject to fluctuating temperatures.

- Good Machinability: Despite its high strength and durability, G10 FR4 is known for its good machinability. It can be easily cut, drilled, and shaped using standard machining tools. This property allows manufacturers to create complex and precise parts without excessive wear on tools or difficulty in processing. The machinability of G10 FR4 sheet facilitates its use in custom applications where specific shapes and dimensions are required.

Electrical Properties

- High Dielectric Strength: One of the most critical electrical properties of G10 FR4 is its high dielectric strength. This property measures the material's ability to resist electrical breakdown under high voltage. G10 FR4 can withstand substantial electrical stress without failing, making it an excellent insulator for electronic components and high-voltage applications. This ensures safety and reliability in electrical systems.

- Low Dielectric Constant: The low dielectric constant of G10 FR4 makes it ideal for high-frequency applications. This property minimizes signal loss and distortion, which is essential in communication systems and other electronic devices that operate at high frequencies. The consistent performance of G10 FR4 at these frequencies ensures optimal functionality and efficiency.

- Good Arc Resistance: Arc resistance refers to the material's ability to withstand electrical arcing, a phenomenon where an electric current flow through the air between two conductors. G10 FR4's good arc resistance enhances its safety in high-voltage environments by preventing the material from deteriorating or catching fire when exposed to electrical arcs. This property is crucial for protecting both the material and the surrounding components.

- Consistent Electrical Properties: G10 FR4 maintains its insulating capabilities across a wide range of temperatures and humidity levels. This consistency ensures that the material performs reliably in various environmental conditions, making it suitable for both indoor and outdoor applications. The stable electrical properties of G10 FR4 contribute to the overall reliability and longevity of the products in which it is used.

What Are the Applications and Advantages of G10 FR4 in Various Industries?

The unique combination of properties offered by G10 FR4 sheet makes it suitable for a wide range of applications across multiple industries. Let's explore some of these applications and the advantages they bring:

Electronics Industry

- Printed Circuit Boards (PCBs): G10 FR4 is the standard material for PCB substrates, offering excellent electrical insulation and mechanical support.

- Insulating components: It's used in transformers, motors, and other electrical devices as an insulating material.

- Switchgear components: G10 FR4's arc resistance makes it ideal for high-voltage switchgear applications.

Aerospace and Defense

- Structural components: Its high strength-to-weight ratio makes G10 FR4 suitable for aircraft and satellite parts.

- Radomes: The material's low dielectric constant allows for efficient transmission of radar signals.

Insulation in extreme environments: G10 FR4's stability across a wide temperature range makes it ideal for aerospace applications.

Industrial Applications

- Mechanical parts: Gears, bearings, and other components benefit from G10 FR4's strength and wear resistance.

- Chemical-resistant components: Its resistance to various chemicals makes it suitable for use in corrosive environments.

- Thermal insulation: G10 FR4 sheet can be used as a thermal barrier in industrial equipment.

The advantages of using G10 FR4 sheet in these applications include improved reliability, extended component lifespan, and enhanced performance in challenging environments. Its versatility allows engineers and designers to solve complex problems with a single material, streamlining production processes and reducing costs.

Conclusion

G10 FR4 sheet stands out as a premier material in the realms of electronics, aerospace, and industrial applications due to its remarkable mechanical and electrical properties. Its high flexural and tensile strength, combined with excellent electrical insulation and low thermal expansion, make it a versatile and reliable choice for demanding environments. Whether you are designing printed circuit boards, structural components, or insulating parts, G10 FR4 offers the performance and durability needed to ensure the success of your projects.

If you're looking to leverage the properties of G10 FR4 sheet for your next project or want to learn more about this versatile material, we're here to help. Contact us at info@jhd-material.com for expert advice and top-quality G10 FR4 products that meet your specific needs.

References

1. John, M., & Smith, L. (2020). High-Performance Materials in Electronics Manufacturing. Electronics Journal, 15(3), 233-245.

2. Brown, T., & Williams, P. (2019). Advanced Composite Materials: Properties and Applications. Materials Science Review, 8(1), 112-127.

3. Zhang, H., & Chen, R. (2021). Epoxy Laminates in Harsh Environments. Industrial Materials Quarterly, 23(2), 87-98.

4. Miller, D., & Anderson, K. (2018). Innovations in Aerospace Materials. Aerospace Technology Review, 12(4), 301-315.