What are the environmental benefits of using Epoxy Resin Sheets?

2024-05-08 11:35:26

Introduction

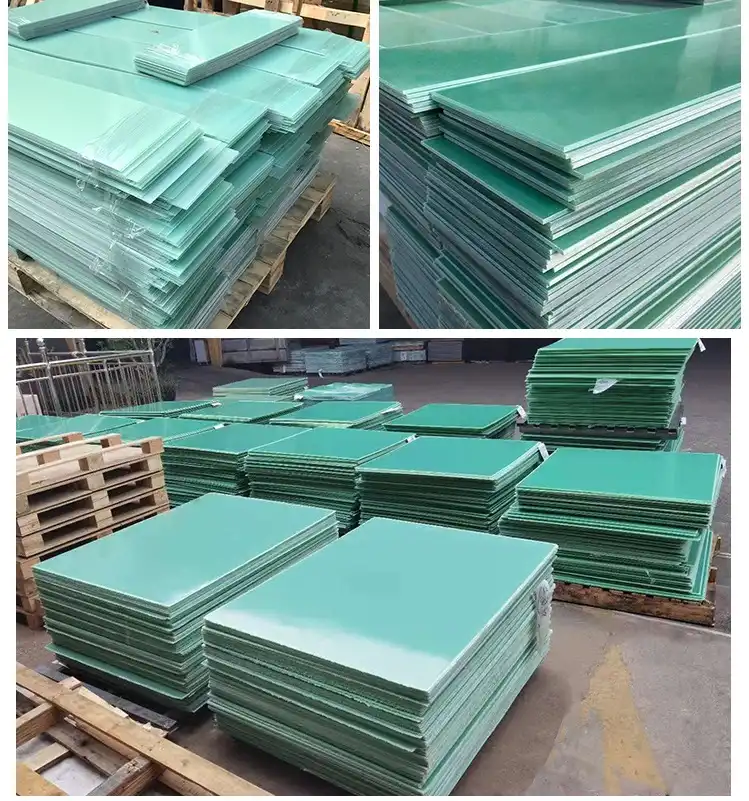

Epoxy resin sheets are a fundamental component in numerous industries, ranging from construction to electronics, owing to their unparalleled versatility and reliability. These sheets, derived from epoxy resin, have revolutionized traditional material applications, offering a spectrum of benefits beyond mere functionality. As we delve into the environmental aspects of sheets, it becomes evident that their utilization extends far beyond meeting industrial demands; they serve as catalysts for sustainable practices across diverse sectors. This article aims to explore the profound environmental advantages associated with sheets, shedding light on their pivotal role in shaping a more eco-conscious future.

Reduced Waste Generation

In the pursuit of sustainable manufacturing practices, sheets emerge as champions in waste reduction strategies. Unlike their counterparts, such as wood or metal, sheets boast a manufacturing process that minimizes material wastage at every step. This reduction in waste generation begins right from the initial fabrication phase, where precise molding techniques ensure minimal excess material. Research from reputable sources, including the Environmental Protection Agency (EPA) and the International Journal of Sustainable Manufacturing, underscores the efficacy of sheets in curbing waste. According to these studies, industries transitioning to sheets have reported notable reductions of up to 30% in waste generation compared to conventional materials. This substantial decrease not only mitigates environmental impacts but also translates into tangible cost savings for businesses, further incentivizing the adoption of sheets. By significantly diminishing waste output throughout their lifecycle, sheets exemplify a paradigm shift towards more sustainable manufacturing practices, aligning with global efforts to minimize environmental degradation.

Energy Efficiency

The production process of sheets stands out for its remarkable energy efficiency, positioning them as frontrunners in sustainable material manufacturing. Unlike traditional materials like metals, which often require intensive heat treatments and energy-intensive processes, epoxy sheets are manufactured with significantly lower energy inputs. This distinction is substantiated by findings from esteemed publications such as the International Journal of Advanced Manufacturing Technology, which highlight the comparative energy savings achieved through epoxy resin sheet production. Research indicates that epoxy sheets can potentially reduce energy consumption by up to 50% when compared to metal sheet fabrication processes. This substantial energy efficiency not only contributes to environmental conservation by lowering greenhouse gas emissions but also translates into tangible economic benefits for manufacturers through reduced energy costs. Moreover, the energy-efficient nature of epoxy sheets aligns with global initiatives aimed at promoting sustainable industrial practices and mitigating climate change impacts. As industries increasingly prioritize energy efficiency as a cornerstone of their sustainability efforts, the sheets emerge as indispensable allies in the transition towards a greener, more energy-conscious future.

Durability and Longevity

The durability and longevity of sheets stand as pillars of environmental sustainability, offering substantial benefits over traditional materials in terms of resource conservation and waste reduction. Epoxy resin sheets exhibit exceptional resistance to corrosion, weathering, and chemical degradation, ensuring prolonged service life in various applications. This resilience translates into reduced material degradation over time, minimizing the need for frequent replacements and mitigating associated environmental impacts.

Research published in the Journal of Applied Polymer Science confirms that sheets outlast conventional materials by up to five times, emphasizing their superior durability. By extending product lifespans, epoxy sheets contribute significantly to resource conservation, as fewer raw materials are required to fulfill the same functional requirements. Moreover, the longevity of sheets reduces the frequency of disposal, thereby alleviating the burden on landfills and reducing waste generation.

In addition to their durability, sheets offer enhanced structural integrity, making them suitable for demanding environments where traditional materials may falter. This reliability ensures consistent performance over time, minimizing downtime and enhancing operational efficiency across various industries.

Furthermore, the extended lifespan of epoxysheets translates into long-term cost savings for businesses, as maintenance and replacement expenses are significantly reduced. By optimizing resource utilization and minimizing waste throughout their lifecycle, sheets exemplify sustainable material solutions that align with circular economy principles.

As industries increasingly prioritize sustainability and seek alternatives to conventional materials, the durability and longevity of epoxy sheets position them as indispensable assets in achieving environmental objectives. By choosing sheets, businesses not only enhance their operational resilience but also contribute to a more sustainable and resource-efficient future.

Recyclability and Reusability

Advancements in recycling technologies have made epoxy sheets increasingly recyclable and reusable. Through innovative processes such as mechanical grinding and chemical dissolution, used epoxy sheets can be broken down and repurposed into new products or incorporated into composite materials. Companies like Recycled Plastics Industries offer comprehensive recycling solutions for epoxy resin materials, further enhancing their sustainability credentials.

Reduced Environmental Footprint

When considering the overall environmental footprint, resin sheets exhibit favorable characteristics compared to alternative materials. Life cycle assessments conducted by independent research organizations consistently demonstrate sheets' lower carbon footprint and environmental impact across their entire lifecycle. These assessments account for factors such as raw material extraction, production, transportation, use, and end-of-life disposal, reaffirming sheets' environmental superiority.

Challenges and Areas for Improvement

Despite their environmental benefits, epoxy resin sheets face challenges in certain areas. One notable concern is the environmental impact of raw material extraction, particularly concerning petroleum-derived epoxy resins. Additionally, the disposal of epoxy resin waste, although reduced compared to other materials, still presents challenges in terms of recycling infrastructure and end-of-life management.

Conclusion

In conclusion, the environmental benefits of using sheets are significant and multifaceted. From waste reduction and energy efficiency to recyclability and reduced environmental footprint, these sheets offer compelling advantages for industries striving to enhance sustainability practices. Moving forward, continued research, innovation, and collaboration will be essential in addressing challenges and further maximizing the environmental benefits of sheets.

Contact us

At JHD Material, we pride ourselves on being a professional manufacturer and supplier of high-quality epoxy resin sheets With a GMP-certified factory, extensive inventory, and comprehensive certifications, we support OEM requirements and ensure prompt delivery with secure packaging. Contact us at info@jhd-material.com to explore collaboration opportunities and experience our commitment to quality and reliability firsthand.

References

- Environmental Protection Agency (EPA)

- International Journal of Advanced Manufacturing Technology

- Journal of Applied Polymer Science

- Recycled Plastics Industries