Study on Modification and Toughening of Epoxy Resin E51

2022-10-17

1. Introduction

Epoxy resin E51 has low viscosity, high epoxy value and curing effect. Its disadvantages are high brittleness and low toughness; E20 and E12 epoxy resins have the advantages of high adhesion and good toughness, but the disadvantage is low hardness. Mix the three kinds of epoxy resins in proportion. The new mixed resin has the characteristics of E51 resin with high activity, good curing effect and high hardness, as well as the advantages of good toughness of E20 and E12 medium long molecular chains. After curing with self-made mixed amine, it improves the performance of the cured product and overcomes the disadvantage of poor comprehensive performance after curing with a single epoxy resin.

2. Experimental

a) The king will try his punishment. Aerobic resin E12, E20, E51, polyether clothing, polyether second clothing, curing agent accelerator; Xylene; N-Butanol.

b) Main instruments. High speed epoxy resin disperser; Electronic scale; UTM4000 series microcomputer controlled electronic universal testing machine; Thermogravimetric differential thermal analyzer EXSTAR6300.

c) Experimental test. 1) Solvent preparation: add n-butanol into xylene and stir evenly. 2) Resin preparation: add epoxy resin E12 and E20 in the solvent according to the proportion, stir at high speed for 20 minutes, add epoxy resin E51 after the resin is dissolved, stir at high speed and mix evenly, and make 4 kinds of mixed solutions with different proportions of the three epoxy resins, numbered resin A, B, C, D. Prepare three solutions of single epoxy resin. 3) Sample test: mix the resin and curing agent with epoxy equivalent=1:0.6, 1:0.7, 1:0.8 and 1:0.9 respectively, dry them at room temperature, apply them on tinplate for bending observation, bond 20mm cylinder for testing with tensile testing machine, measure the hardness with Shore hardness tester, and conduct differential thermal analysis with differential thermal analyzer.

3. Results and Discussion

a) Bending observation. E51, E12 and B and D in the resin have bending angles less than or equal to 90 °. The minimum angle of fracture is E12, 60 °; D The minimum fracture angle of smear is 70 °; E51 Fracture angle is 85 °. The mixed resin has good fracture resistance. On the one hand, the three resins have long, medium and short chains, and the proportion is appropriate. The integrity of the long chain is guaranteed during the mixing process. The long, medium and short cross doping makes the stress dispersion more uniform; On the other hand, the flexible chain segment in the mixed amine is linked to the network of the epoxy resin, resulting in micro phase separation during the curing process, which forms a tight and loose phase network structure, breaking the uniformity of the original cross-linking network. This network is conducive to stress dispersion, causing plastic deformation within the cured product, thus increasing the toughness of 111.

b) Tensile test. The tensile test was carried out on a 20mm cylindrical sample. The tensile strength of epoxy resin E51 was 16.176MP, the breaking force was 5196.13N, and the deformation was 5.24mm; The tensile strength of modified resin D is 16.053MP, the breaking force is 5114.97N, and the deformation is 5.63mm. The test results show that the optimum equivalent ratio is 1:0.8. It can be seen that the molecular weight, reaction activity, crosslinking density of epoxy resin, the compatibility of each component of the system, and the addition amount of curing agent are the main factors affecting the mechanical properties.

c) Hardness measurement. The hardness of cured epoxy resins was tested. The results showed that when the equivalent ratio was 1:0.8, the Shore hardness values of resin D and E51 were 96.2 and 95. With the increase of the amount of curing agent, the hardness decreases, but in general, the amount of curing agent has little influence on the cured products, and the proportion of epoxy resin has a greater influence.

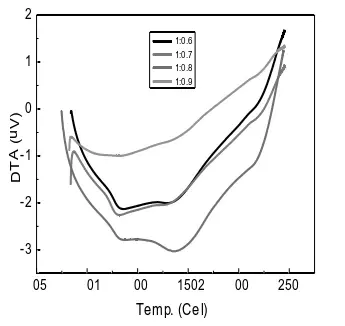

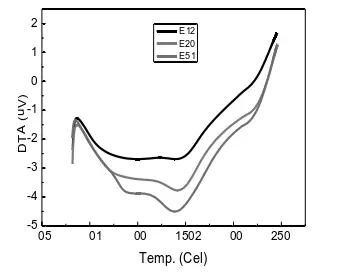

d) Differential thermal analysis. The cured resin was analyzed by differential thermal analysis. The heating rate was 20 ℃/min. The results are as follows:

With the increase of temperature, the curve has two peaks, and the curing reaction at room temperature is incomplete. The curing process is divided into two stages, the curing temperature is 85 ℃ and 132 ℃, the amount of curing agent has little influence on the curing temperature.

With the increase of temperature, the first peak of resin E12 and E20 is not obvious, the curing reaction of resin E12 and E20 is relatively complete at room temperature, and the second peak appears at 139 ℃ and 141 ℃. The double peaks of E51 are obvious, appearing at 93 ℃ and 138 ℃, and the room temperature curing reaction is incomplete. The epoxy equivalent determines the curing temperature of the first stage. The smaller the equivalent value, the lower the curing temperature and the greater the curing degree; The negative is the opposite; The second stage curing temperature has little effect.

Double peaks occur because the addition reaction rate of primary amine group and epoxy group in the curing agent is faster than that of secondary amine group and epoxy group, which makes the first exothermic peak appear at about 93 ℃. As the reaction proceeds, the degree of the system increases, causing difficulty in the movement of the molecular chain segment. Only when the temperature is raised again, the epoxy group can continue to react with the secondary amine group with relatively low reaction activity and the active hydrogen on the server group, the second exothermic peak appeared near 138 ℃, which can be attributed to the secondary addition reaction of secondary amine group, server group and epoxy group.

|

|

| DTA curve of cured resin D | DTA curve of three cured epoxy resins when equivalent ratio is 1:0.8 |

4. Conclusion

(1) The proportion of modified resin and the addition amount of curing agent were determined. Resin D combines the excellent properties of three kinds of epoxy resins, and has good toughness, hardness and bonding strength. (2) The bending fracture angle of the modified epoxy resin system increased (15%~17%), the tensile deformation increased (0.3~0.5mm), the tensile strength decreased (0.05~0.16MP), and the tensile strength remained above 16MP. (3) The hardness of modified E51 is higher. (4) The curing of cured resin D was incomplete at room temperature. The reaction was divided into two stages, the curing temperature was 87 ℃ and 136 ℃. The curing reaction of this system was more appropriate at 85~140 ℃.