Related issues with halogen-free insulation sheets on circuit boards

2023-12-21

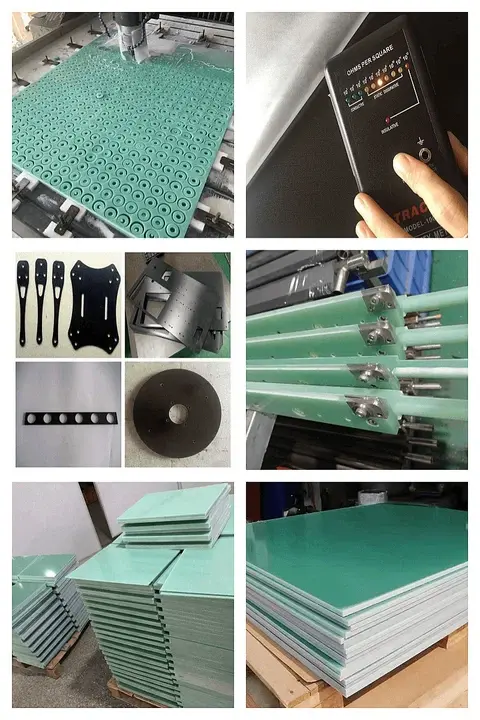

For those who work in the electrical and electronic industry, I believe they often encounter problems with halogen-free insulation boards and their processing, whether they are large or small. Halogen-free insulation boards are formed by soaking electronic grade fiberglass cloth and halogen-free epoxy resin, and hot pressing them. They are the most commonly used materials for insulation structural components in motor electrical equipment due to their high mechanical and dielectric properties. Let's take a look at common problems together:

Analysis of the advantages and disadvantages of ordinary epoxy resin board and halogen-free board in the circuit board industry:

1. Advantages: The halogen-free board, due to its absence of halogen elements, conforms to environmental protection concepts and meets the needs of the future world for environmental protection.

2. Disadvantages: Due to the absence of halogen, the brittleness of halogen-free boards increases, making them prone to white spots. This puts forward more stringent process requirements for solder mask production and shape processing.

Introduction to the uses and related knowledge of single panel and insulation board:

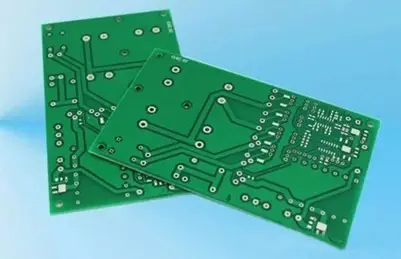

Single panel and insulation board are both boards used in electronic circuits. Single panel, in simple terms, refers to the most basic PCB where parts are concentrated on one side and wires are concentrated on the other side. The reason why it is called a single panel is because the wires only appear on one side. Because single panels have many strict limitations in designing circuits (because they are only on one side, wiring cannot cross and must follow separate paths), only early circuits used such boards;

And insulation board, in simple terms, non-conductive board is insulation board. Usually, insulation material stores sell varieties such as bakelite, PVC, PE, PP, ABS, nylon, organic glass, epoxy board, etc. In addition, wooden boards, glass, slate, ceramic tiles, etc. are also insulation boards. Often referred to as insulation pads, insulation blankets, or other insulation materials, they are made of adhesive insulation materials, and there should be no harmful irregularities on the upper and lower surfaces of the insulation pads. The harmful irregularity of insulation pads refers to one of the following characteristics, namely, defects that disrupt uniformity and smooth surface contours, such as small holes, cracks, local protrusions, incisions, inclusions of conductive foreign objects, creases, gaps, concave and convex ripples, and casting marks. Harmless irregularity refers to the surface irregularity formed during the production process.

Halogen free insulation boards are widely used in substations, power plants, distribution rooms, laboratories, and field live work.

Hebei Jinghong Electronic Technology Co., Ltd. produces and sells high-quality halogen-free insulation boards, insulation pipes, and epoxy resins. Its main products include: FR4 epoxy sheet, 3240 epoxy sheet, bakelite board, phenolic cotton cloth sheet, 3640 epoxy tube, FR4 epoxy tube, 3520 phenolic paper tube, etc.