Raw materials and characteristics of insulation sheet

2024-12-26 17:03:36

Insulation sheets are essential components in various industries, providing thermal, electrical, and acoustic insulation for a wide range of applications. These versatile materials are crafted from carefully selected raw materials, each contributing unique properties to the final product. The characteristics of insulation sheets are determined by their composition, manufacturing process, and intended use. From fiberglass and mineral wool to foam plastics and natural fibers, the raw materials used in insulation sheets offer diverse benefits such as heat resistance, fire retardancy, moisture control, and sound absorption. Understanding the raw materials and characteristics of insulation sheets is crucial for selecting the right product for specific applications, ensuring optimal performance and energy efficiency in residential, commercial, and industrial settings.

Raw Materials Used in Insulation Sheet Production

Synthetic Fibers and Polymers

Synthetic fibers and polymers play a pivotal role in the production of high-performance insulation sheets. Materials such as polyethylene, polypropylene, and polyurethane are commonly utilized due to their excellent thermal resistance and moisture-repelling properties. These synthetic materials can be engineered to achieve specific insulation characteristics, making them suitable for a wide range of applications. The molecular structure of these polymers allows for the creation of closed-cell foam insulation, which provides superior thermal performance by trapping air within its cellular structure.

Natural and Recycled Materials

In response to growing environmental concerns, many manufacturers are incorporating natural and recycled materials into their insulation sheet production. Cellulose, derived from recycled paper products, is gaining popularity as an eco-friendly insulation option. Other natural materials like wool, cotton, and hemp are also being utilized for their inherent insulating properties and sustainability. These materials offer the added benefit of being renewable resources, reducing the carbon footprint associated with insulation production. Additionally, recycled materials such as denim fibers and plastic bottles are being repurposed to create effective insulation sheets, contributing to waste reduction efforts.

Mineral-Based Insulation Materials

Mineral-based insulation materials have long been a staple in the industry due to their excellent fire resistance and durability. Fiberglass, composed of fine glass fibers, is widely used for its thermal insulation properties and cost-effectiveness. Mineral wool, also known as rock wool, is another popular choice, offering superior sound insulation and fire resistance. These materials are inorganic, making them resistant to mold growth and pest infestation. Vermiculite and perlite, both expanded minerals, are utilized in specialized insulation applications where lightweight and non-combustible properties are required.

Key Characteristics of Insulation Sheets

Thermal Conductivity and R-Value

The primary function of insulation sheets is to minimize heat transfer, and this is quantified through thermal conductivity and R-value. Thermal conductivity, measured in watts per meter-kelvin (W/mK), indicates how readily heat flows through a material. Lower thermal conductivity values signify better insulation properties. R-value, on the other hand, measures the thermal resistance of the insulation sheet. A higher R-value indicates superior insulating performance. These characteristics are crucial for determining the effectiveness of insulation sheets in maintaining desired temperatures and reducing energy consumption in various applications.

Fire Resistance and Safety Features

Fire resistance is a critical characteristic of insulation sheets, particularly in building applications. Many insulation materials are treated with fire retardants or inherently possess fire-resistant properties. The fire performance of insulation sheets is typically evaluated based on flame spread and smoke development indices. Some advanced insulation sheets incorporate intumescent properties, which cause the material to expand and form a protective char layer when exposed to high temperatures. These safety features not only protect the structure but also provide crucial time for occupants to evacuate in case of a fire.

Moisture Resistance and Vapor Permeability

The ability of insulation sheets to manage moisture is vital for maintaining their performance and preventing issues such as mold growth and structural damage. Moisture resistance refers to the material's capacity to repel water and maintain its insulating properties when exposed to humidity. Vapor permeability, measured in perms, indicates how easily water vapor can pass through the insulation. Some insulation sheets are designed to be vapor barriers, preventing moisture migration, while others allow for controlled vapor diffusion. Balancing these characteristics is essential for creating a healthy indoor environment and preserving the integrity of the building envelope.

Applications and Performance Considerations

Building and Construction Industry

In the building and construction industry, insulation sheets play a crucial role in enhancing energy efficiency and occupant comfort. They are utilized in walls, roofs, and floors to create thermal barriers that minimize heat loss in winter and heat gain in summer. The selection of insulation sheets for construction applications requires careful consideration of factors such as climate, building design, and local building codes. High-performance insulation sheets can significantly reduce heating and cooling costs while contributing to a more sustainable built environment. Additionally, acoustic insulation sheets are employed to improve sound attenuation between spaces, enhancing the overall quality of living and working environments.

Industrial and HVAC Applications

Industrial settings and HVAC frameworks display one of a kind challenges for insulation sheets, frequently requiring materials that can withstand extraordinary temperatures and harsh environments. In these applications, insulation sheets are utilized to avoid warm misfortune from pipes, ducts, and equipment, improving vitality proficiency and prepare control. High-temperature insulation sheets, frequently made from ceramic strands or aerogels, are utilized in mechanical heaters and ovens. In HVAC frameworks, cover sheets offer assistance keep up steady temperatures all through ductwork, avoiding condensation and vitality misfortunes. The durability and chemical resistance of cover materials are fundamental in these applications to guarantee long-term execution and security.

Specialized and Emerging Applications

The evolving technology landscape has led to the development of specialized insulation sheets for emerging applications. In the electronics industry, thin insulation sheets with high dielectric strength are used to protect sensitive components and manage thermal dissipation. The automotive sector utilizes lightweight, high-performance insulation sheets to improve vehicle efficiency and passenger comfort. Aerospace applications demand insulation materials that can withstand extreme temperature fluctuations and provide reliable performance in demanding environments. As renewable energy technologies advance, specialized insulation sheets are being developed for solar panels and energy storage systems, contributing to improved efficiency and durability of these critical components.

Conclusion

The raw materials and characteristics of insulation sheets are fundamental to their performance across various applications. From traditional fiberglass and mineral wool to advanced synthetic polymers and eco-friendly natural materials, the diversity of options allows for tailored solutions to meet specific insulation needs. The key characteristics of thermal resistance, fire safety, and moisture management work in concert to provide effective insulation solutions. As technology advances and environmental concerns grow, the development of innovative insulation materials continues to push the boundaries of performance and sustainability. Understanding these aspects is crucial for professionals in construction, engineering, and industrial design to make informed decisions and optimize energy efficiency in their projects.

Contact Us

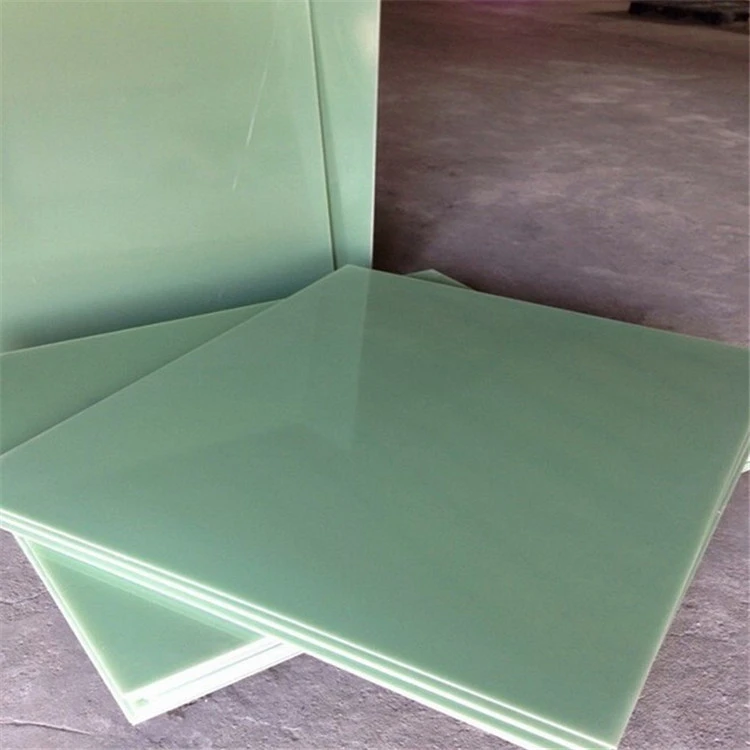

To learn more about our high-quality insulation sheets(FR4 sheet,3240 epoxy sheet,bakelite board,phenolic cotton sheet) and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your needs.

References

1. Smith, J. (2022). Advanced Insulation Materials: Properties and Applications. Journal of Building Physics, 45(3), 267-289.

2. Johnson, A., & Brown, M. (2021). Eco-friendly Insulation Solutions for Sustainable Construction. Green Building Materials Review, 18(2), 123-140.

3. Thompson, R. (2023). Thermal Performance of Novel Insulation Sheets in Industrial Settings. Industrial Energy Efficiency, 56(4), 401-418.

4. Lee, S., & Park, K. (2022). Fire Resistance Characteristics of Modern Insulation Materials. Fire Safety Journal, 129, 103473.

5. Garcia, M., et al. (2021). Moisture Management in Building Insulation: A Comprehensive Review. Construction and Building Materials, 315, 125728.

6. Wilson, D. (2023). Emerging Applications of High-Performance Insulation Sheets in Electronics and Aerospace. Advanced Materials Technologies, 8(5), 2200186.