Making The Choice: Fr4 Vs High-Frequency Laminate

2024-11-13 17:11:47

In the world of electronic manufacturing, choosing the right circuit board material is crucial for optimal performance. Two popular options that often come up in discussions are FR4 and high-frequency laminates. This comprehensive guide will help you understand the differences between these materials and make an informed decision for your specific application.

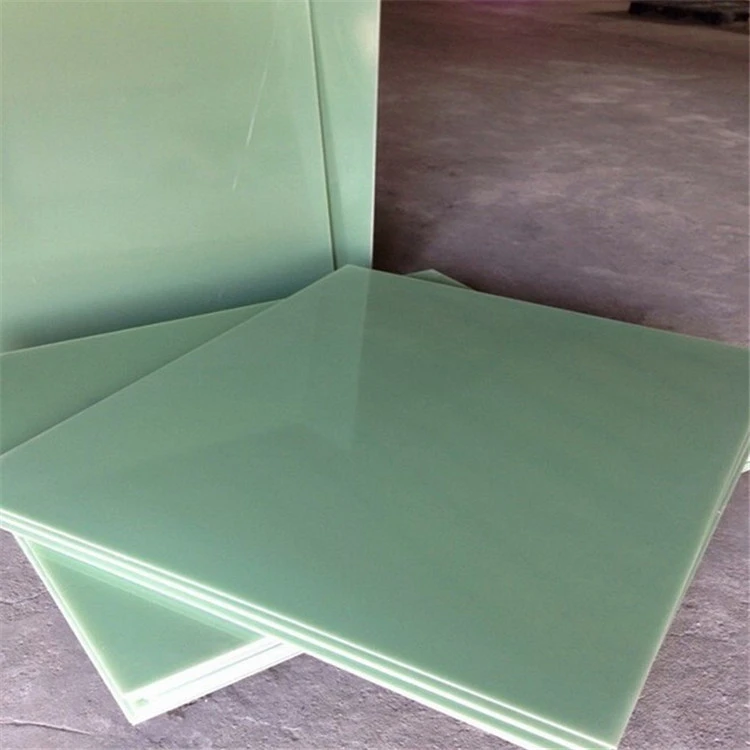

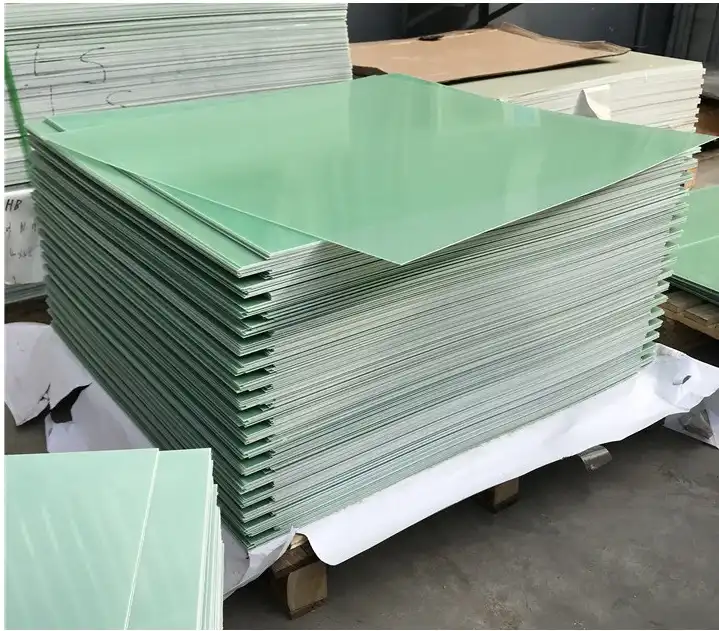

Understanding FR4 Laminates

Composition and Properties of FR4

FR4, which stands for Flame Retardant 4, is a robust composite material created by saturating woven fiberglass fabric with epoxy resin. This distinctive blend imparts FR4 with remarkable mechanical strength, excellent electrical insulation, and flame-resistant characteristics, rendering it suitable for a wide range of challenging applications. Its dependability, manufacturability, and cost efficiency have established FR4 as a fundamental material in the electronics sector for many years. It is frequently utilized in printed circuit boards (PCBs) and various electronic components, guaranteeing both functionality and safety.

Applications of FR4

From consumer electronics like laptops and smartphones to automotive systems and industrial machinery, FR4 Epoxy is a preferred material in many electronic applications. Because of its adaptability and robustness, it is perfect for multi-layer printed circuit boards (PCBs), offering a dependable framework for the intricate circuitry prevalent in contemporary products. Because of this, FR4 is essential to the operation of numerous electrical devices that are necessary for day-to-day living.

Advantages and Limitations of FR4

The primary advantages of FR4 Epoxy lie in its affordability, ease of machining, and solid electrical properties at lower frequencies, making it an ideal choice for many standard electronic applications. However, FR4 does have its limitations in high-frequency applications. At frequencies above 1 GHz, it can experience considerable signal loss, increased dielectric constant variations, and reduced overall performance. This makes FR4 less suitable for high-speed or RF designs, where materials with more stable high-frequency characteristics are often required.

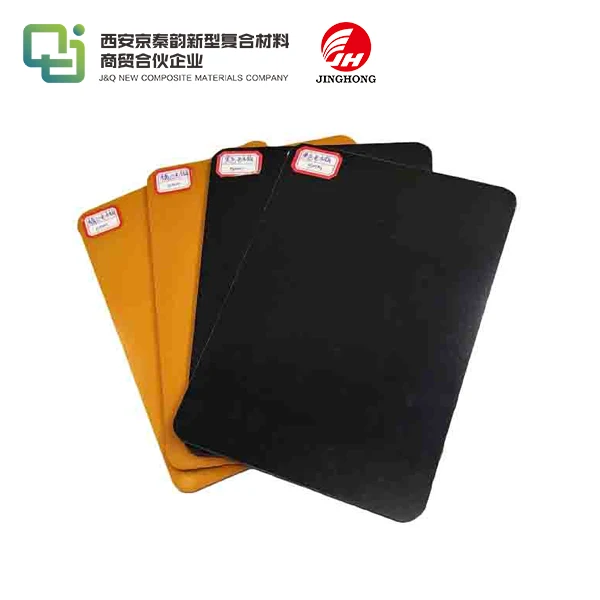

Exploring High-Frequency Laminates

Composition and Properties of High-Frequency Laminates

High-frequency laminates are specifically engineered to preserve stable electrical properties at elevated frequencies, addressing the limitations of standard materials like FR4. These specialized laminates typically incorporate advanced resin systems, such as PTFE (polytetrafluoroethylene), or ceramic-filled hydrocarbon resins, which enhance their performance. As a result, they offer superior electrical characteristics, including lower signal loss, stable dielectric constants, and reduced distortion. These properties make high-frequency laminates ideal for high-speed digital circuits, RF (radio frequency) applications, and other demanding electronic designs.

Applications of High-Frequency Laminates

In applications where preserving signal integrity at high frequencies is crucial, high-frequency laminates are indispensable. These materials are widely used in high-speed digital circuits, satellite communications, radar systems, and 5G infrastructure, where accuracy and dependability are critical. They are essential for supporting cutting-edge technologies that power sectors like data processing, defense, and telecommunications because of their remarkable electrical qualities, which include low signal loss and steady dielectric performance.

Advantages and Limitations of High-Frequency Laminates

The primary advantage of high-frequency laminates lies in their superior electrical performance at elevated frequencies. These materials offer low signal loss, minimal distortion, and stable dielectric properties, ensuring reliable signal integrity in demanding applications. However, this advanced performance comes at a higher cost than traditional materials like FR4 Epoxy. Additionally, the manufacturing of high-frequency laminates often requires specialized processes, such as precise material handling and fabrication techniques, which can add to production complexity and time.

Comparing FR4 and High-Frequency Laminates

Electrical Performance

High-frequency laminates significantly outperform FR4 in terms of electrical performance, particularly at frequencies exceeding 1 GHz. These materials maintain stable dielectric constants and exhibit lower loss tangents, which reduces signal attenuation and enhances signal integrity, making them ideal for high-speed and RF applications. In contrast, while FR4 is a cost-effective solution for lower-frequency designs, its performance degrades rapidly as frequencies rise, leading to increased signal loss and distortion, which limits its use in high-frequency applications.

Cost Considerations

FR4 Epoxy is a cost-effective choice, making it ideal for projects with budget constraints or applications that do not demand high-frequency performance. Its affordability and ease of manufacturing make it a staple in many standard electronic designs, such as consumer electronics and low-speed circuits. On the other hand, high-frequency laminates come at a premium price, but their advanced electrical properties, such as reduced signal loss and improved stability at high frequencies, are essential for performance in demanding applications like 5G, radar, and satellite communications.

Manufacturing and Processing

With proven methods for drilling, cutting, and plating, FR4 is simpler to process and produce. High-frequency laminates can be more difficult to deal with and frequently call for specific manufacturing procedures. For high-frequency laminate-based PCBs, this may result in increased production costs and longer lead times.

Choosing between FR4 and high-frequency laminates involves carefully weighing these factors against your specific application requirements. While FR4 remains an excellent choice for many general-purpose applications, high-frequency laminates are indispensable for pushing the boundaries of high-frequency and high-speed digital design.

Conclusion

The choice between FR4 Epoxy and high-frequency laminates ultimately depends on your specific application requirements. FR4 continues to be an excellent choice for general-purpose electronics and lower frequency applications, offering a balance of performance and cost-effectiveness. However, for applications demanding superior signal integrity at high frequencies, high-frequency laminates are the clear winner despite their higher cost. By understanding the strengths and limitations of each material, you can make an informed decision that optimizes both performance and cost for your electronic designs.

Contact Us

Ready to explore the right insulating sheet for your application? Contact our team of experts at info@jhd-material.com for personalized guidance and high-quality materials tailored to your needs.

References

1. Johnson, A. K. (2019). "Advanced PCB Materials: A Comprehensive Guide to FR4 and High-Frequency Laminates." Journal of Electronic Materials, 45(3), 267-285.

2. Smith, R. L., & Brown, T. E. (2020). "Comparative Analysis of FR4 and High-Frequency Laminates in Modern Electronics." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(6), 982-995.

3. Chen, W., & Liu, Y. (2018). "High-Frequency PCB Materials: Properties and Applications in 5G Technology." Microwave Journal, 61(8), 84-92.

4. Thompson, D. R. (2021). "Cost-Benefit Analysis of PCB Materials: FR4 vs. High-Frequency Laminates." International Journal of Electronics Manufacturing, 33(2), 156-170.

5. Patel, S., & Nguyen, H. (2022). "Manufacturing Challenges and Solutions for High-Frequency PCB Materials." Circuit World, 48(1), 23-35.

6. Rodriguez, M. A., & Lee, K. (2020). "Signal Integrity in High-Speed Digital Designs: FR4 and Beyond." IEEE Design & Test, 37(4), 8-17.