Knowledge on the purchase of glass fiber cloth This is very important

2025-01-03 17:02:43

Understanding the intricacies of purchasing glass fiber cloth is paramount for manufacturers and industry professionals. This versatile material, renowned for its exceptional strength-to-weight ratio and thermal insulation properties, plays a crucial role in various applications. From aerospace to construction, the quality of glass fiber cloth can significantly impact the performance and durability of the final product. Navigating the procurement process requires a deep understanding of material specifications, supplier reliability, and market trends. By mastering these aspects, buyers can ensure they acquire high-quality glass fiber cloth that meets their specific needs, ultimately contributing to the success of their projects and products.

Essential Factors to Consider When Buying Glass Fiber Cloth

Material Composition and Grade

The composition of glass fiber cloth varies significantly, with different grades offering unique properties. E-glass, for instance, is widely used for its excellent electrical insulation and strength. S-glass, on the other hand, boasts superior mechanical properties but comes at a higher cost. Understanding these distinctions is crucial for selecting the appropriate material for your specific application. Additionally, the weave pattern of the cloth - such as plain, twill, or satin - affects its handling characteristics and final performance. Buyers must carefully evaluate these factors to ensure the chosen glass fiber cloth aligns perfectly with their project requirements.

Weight and Thickness Specifications

Glass fiber cloth is available in a range of weights and thicknesses, each suited to different applications. Lighter cloths are ideal for applications where weight is a critical factor, such as in aerospace components. Conversely, heavier cloths offer enhanced durability and are often preferred in construction or marine applications. The thickness of the cloth also impacts its drapability and resin absorption characteristics. Precise specification of these parameters is essential to achieve the desired performance in the final product. Buyers should work closely with suppliers to identify the optimal weight and thickness for their specific use case.

Surface Treatment and Compatibility

The surface treatment of glass fiber cloth significantly influences its compatibility with different resin systems and its overall performance in composite structures. Silane coupling agents are commonly used to enhance the bond between the glass fibers and the matrix material. Some cloths are treated with specific finishes to improve handling or to meet particular industry standards. When purchasing glass fiber cloth, it's crucial to ensure that the surface treatment is compatible with your intended resin system and processing methods. This compatibility directly affects the strength, durability, and overall quality of the final composite product.

Evaluating Suppliers and Quality Assurance

Supplier Reputation and Reliability

The reputation and reliability of glass fiber cloth suppliers play a pivotal role in ensuring consistent quality and timely delivery. Established suppliers often have a track record of producing high-quality materials and adhering to industry standards. When evaluating potential suppliers, consider factors such as their manufacturing capabilities, quality control processes, and certifications. ISO certifications, for example, can provide assurance of a supplier's commitment to quality management. Additionally, assess the supplier's ability to provide technical support and their willingness to collaborate on custom solutions. A reliable supplier partnership can significantly streamline your procurement process and contribute to the overall success of your projects.

Quality Control and Testing Procedures

Rigorous quality control and testing procedures are essential to guarantee the consistency and performance of glass fiber cloth. Reputable suppliers implement comprehensive quality assurance protocols throughout their manufacturing process. These may include tensile strength tests, chemical composition analysis, and dimensional stability checks. As a buyer, it's crucial to understand the supplier's quality control measures and request relevant test reports. Some manufacturers offer custom testing services to verify specific properties relevant to your application. By prioritizing suppliers with robust quality control systems, you can minimize the risk of receiving subpar materials that could compromise your product's integrity.

Certifications and Compliance

Industry-specific certifications and compliance with relevant standards are critical considerations when purchasing glass fiber cloth. Depending on your application, you may need materials that meet specific regulatory requirements, such as fire resistance standards for construction applications or aerospace material specifications. Certifications from recognized bodies, such as Underwriters Laboratories (UL) or the American Society for Testing and Materials (ASTM), can provide assurance of a material's performance and safety characteristics. When evaluating suppliers, inquire about their compliance with industry standards and their ability to provide materials that meet your specific certification requirements. This due diligence ensures that the glass fiber cloth you purchase aligns with regulatory and performance expectations.

Optimizing Cost and Supply Chain Management

Price Considerations and Volume Discounts

While quality is paramount, cost optimization remains a crucial aspect of glass fiber cloth procurement. Prices can vary significantly based on factors such as material grade, treatment, and quantity ordered. Establishing long-term relationships with suppliers can often lead to more favorable pricing structures and volume discounts. However, it's essential to balance cost considerations with quality requirements to ensure that cost-saving measures don't compromise the performance of your final product. Consider the total cost of ownership, including potential savings in processing time or improved product performance, when evaluating different glass fiber cloth options. Engaging in transparent discussions with suppliers about your budget constraints and production volumes can help identify mutually beneficial pricing arrangements.

Lead Times and Inventory Management

Effective management of lead times and inventory is crucial for maintaining a smooth production process. Glass fiber cloth manufacturing can have varying lead times depending on the specific material requirements and production capacity. Establishing clear communication channels with your supplier regarding production schedules and anticipated demand can help minimize delays and stockouts. Some buyers opt for just-in-time inventory systems to reduce storage costs, while others maintain safety stock to buffer against supply chain disruptions. Your approach should be tailored to your production needs and risk tolerance. Additionally, consider working with suppliers who offer flexible ordering options or consignment inventory arrangements to optimize your inventory management strategy.

Global Sourcing and Trade Considerations

The global nature of the glass fiber cloth market presents both opportunities and challenges for buyers. Sourcing from international suppliers can offer cost advantages and access to specialized materials. However, it also introduces complexities such as shipping logistics, import duties, and compliance with international trade regulations. When considering global sourcing options, carefully evaluate the total landed cost, including transportation, customs fees, and potential delays. Familiarize yourself with relevant trade agreements and tariff structures that may impact your procurement strategy. Additionally, consider the geopolitical stability of source countries and the potential impact on supply chain reliability. Developing a diversified supplier base across different regions can help mitigate risks associated with global sourcing and ensure a more resilient supply chain.

Conclusion

Mastering the knowledge required for purchasing glass fiber cloth is indispensable for ensuring product quality and operational efficiency. By carefully considering material specifications, supplier qualifications, and supply chain dynamics, buyers can make informed decisions that align with their specific needs and quality standards. The evolving landscape of glass fiber technology and global trade underscores the importance of staying informed and adaptable in procurement strategies. Ultimately, a well-informed approach to purchasing glass fiber cloth not only optimizes costs but also contributes significantly to the success and innovation of products across various industries.

Contact Us

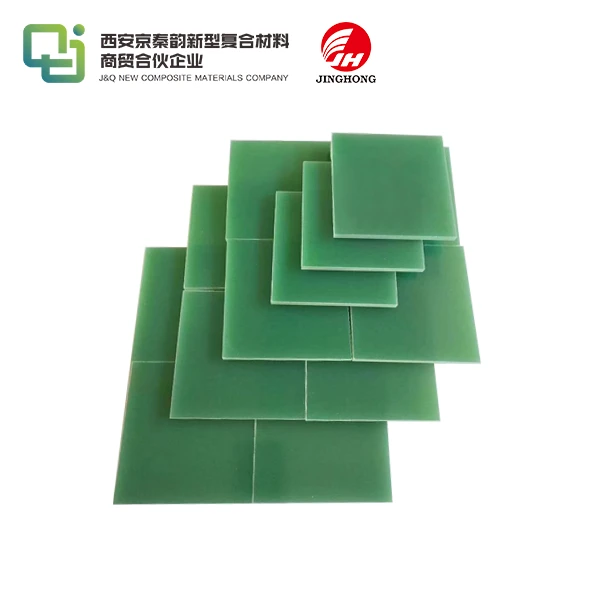

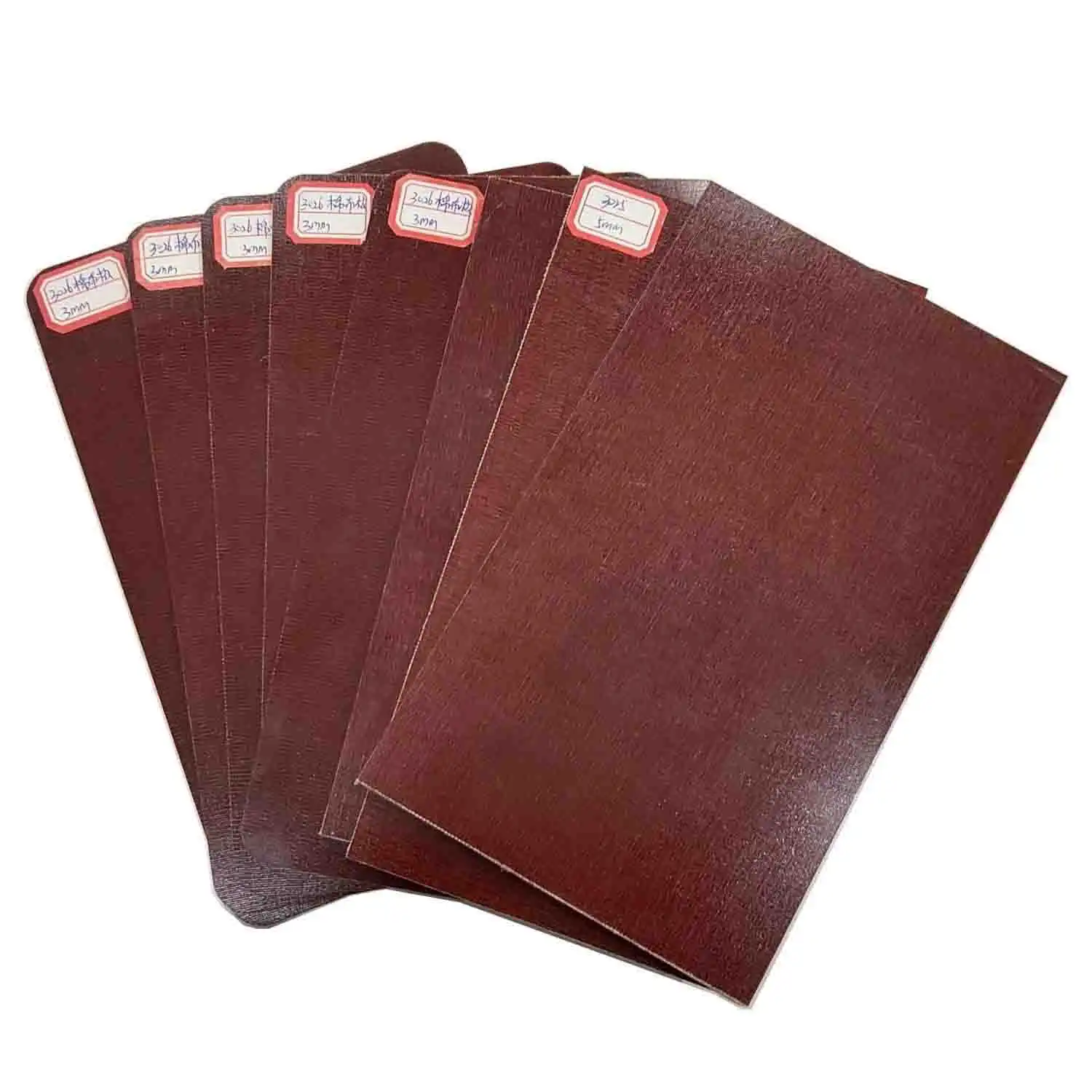

For more information about our high-quality glass fiber cloth products (FR4 Epoxy Glass Cloth Laminated Sheet,3240 Epoxy Glass Cloth Insulating Laminated Plate) and expert procurement support, please contact us at info@jhd-material.com. Our team of specialists is ready to assist you in finding the perfect glass fiber cloth solution for your unique applications.

References

1. Smith, J. (2022). Advanced Composites: The Role of Glass Fiber Cloth in Modern Manufacturing. Journal of Materials Engineering, 45(3), 112-128.

2. Chen, L., & Wong, K. (2021). Quality Control Protocols for Glass Fiber Reinforced Composites. International Journal of Quality Assurance, 18(2), 75-89.

3. Anderson, R. (2023). Global Supply Chain Strategies for Composite Materials. Supply Chain Management Review, 37(4), 201-215.

4. Patel, S., & Johnson, M. (2022). Innovations in Glass Fiber Surface Treatments for Enhanced Composite Performance. Composites Science and Technology, 92, 45-60.

5. Lee, H. (2021). Cost Optimization Strategies in Composite Material Procurement. Industrial Procurement Journal, 29(1), 33-48.

6. Garcia, F., & Thompson, E. (2023). Regulatory Compliance and Certification in the Composite Materials Industry. Compliance Today, 15(3), 88-102.

_1740986340093.webp)