Is PP plastic safe?

2024-10-08 14:15:40

In today's world, where plastic materials are ubiquitous, it's crucial to understand the safety and applications of different types of plastics. One such material that has gained significant popularity in various industries is polypropylene (PP). This versatile thermoplastic polymer is widely used in the manufacture of PP plate sheets, polypropylene boards, and pp plastic sheets. But the question remains: Is PP plastic safe? Let's delve into the world of polypropylene to explore its safety profile, applications, and why it has become a preferred choice for many manufacturers and consumers alike.

The Safety Profile of Polypropylene

Chemical Composition and Inertness

Polypropylene is a thermoplastic polymer made from propylene monomers. Its chemical structure consists of long chains of carbon and hydrogen atoms, which contribute to its stability and inertness. This chemical composition makes PP resistant to many chemicals, acids, and bases, reducing the likelihood of harmful interactions with other substances.

Food-Grade Certification

One of the most compelling arguments for the safety of PP plastic is its food-grade certification. Regulatory bodies such as the U.S. Food and Drug Administration (FDA) have approved polypropylene for food contact applications. This certification indicates that PP does not leach harmful chemicals into food or beverages under normal conditions, making it a safe choice for food packaging and storage containers.

Low Toxicity and Environmental Impact

Polypropylene is one of the few plastics with low levels of toxicity. It does not contain phthalates or bisphenol A (BPA), two potentially hazardous chemicals that are found in other plastics. Additionally, PP can be recycled, enhancing its environmental credentials. PP plastic sheets and boards can be reused, reducing their impact on the environment, when disposed of and recycled appropriately.

Applications of PP Plate Sheets and Polypropylene Boards

Industrial Uses

PP plate sheets and polypropylene boards are increasingly vital in various industrial sectors due to their remarkable durability and chemical resistance. These materials are lightweight, making them easy to handle, which is crucial for manufacturing equipment components, storage tanks, and protective coverings. Industries like automotive, electronics, and construction benefit from their versatility, as they can be tailored to meet specific needs, offering a cost-effective solution for a wide range of applications. Their reliability under demanding conditions further enhances their appeal in the market.

Consumer Products

PP plastic sheets are a crucial component in the production of a wide range of consumer goods. Food containers, cutting boards, outdoor furniture, and toys for children all demonstrate their adaptability. Polypropylene is ideal for products that directly interact with users because of its high safety profile. Additionally, because it can withstand high temperatures, it is suitable for hot-fill packaging and microwave-safe containers, making it easier to use on a daily basis. Polypropylene has established itself as a market-trusted material thanks to this dependability.

Medical and Laboratory Equipment

The medical field significantly benefits from the safety and versatility of polypropylene. PP plate sheets are essential in producing laboratory equipment, medical devices, and pharmaceutical packaging. Their resistance to sterilization processes ensures that these items can be effectively cleaned and reused without compromising safety. Moreover, polypropylene maintains its integrity under various environmental conditions, making it ideal for healthcare settings where hygiene and reliability are critical. This reliability enhances patient safety and contributes to the overall efficiency of medical operations.

Advantages of Using PP Plastic Sheets

Durability and Longevity

PP plastic sheets boast exceptional durability, resisting cracks, breaks, and chemical degradation. This longevity translates to reduced waste and replacement costs, making polypropylene an economical choice for long-term applications. Whether used in outdoor signage or indoor fixtures, PP sheets maintain their structural integrity over time, even when exposed to various environmental factors.

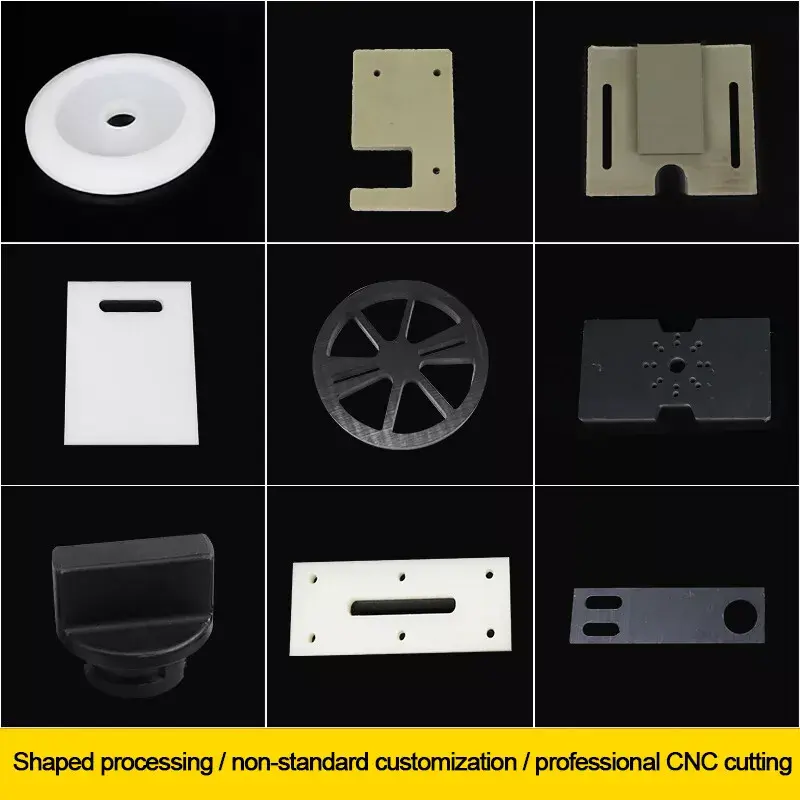

Versatility in Manufacturing

The versatility of polypropylene in manufacturing processes is unparalleled. PP plate sheets can be easily molded, thermoformed, or machined to create complex shapes and designs. This flexibility allows manufacturers to produce a wide range of products with minimal material waste. From intricate components to large-scale structures, polypropylene adapts to diverse manufacturing needs without compromising on quality or safety.

Cost-Effectiveness

PP plastic sheets are frequently the more economical choice when contrasted with alternative materials that possess comparable qualities. Polypropylene is a reasonably cheap raw material, and its simplicity of processing helps to keep manufacturing prices down. Furthermore, PP goods' longevity lowers replacement and maintenance costs over time, which makes them a desirable option for companies trying to strike a compromise between quality and cost.

Conclusion

In conclusion, PP plastic's safety has been thoroughly investigated, validated by regulatory bodies, and widely employed in a variety of industries. Polypropylene boards, PP plastic sheets, and PP plate sheets provide an unrivaled blend of affordability, adaptability, and safety. Polypropylene is a dependable option as we search for safe and sustainable materials for both industrial and everyday use.

Contact Us

With over 20 years of experience in producing and selling insulating sheets and more than a decade in foreign trading, our company is at the forefront of providing high-quality PP plastic products. Our longstanding cooperation with domestic and foreign trading companies enables us to offer unparalleled service and expertise in the field of polypropylene materials. For more information about our range of PP plate sheets, polypropylene boards, and pp plastic sheets, please don't hesitate to reach out to us at info@jhd-material.com.

References

1. Smith, J. (2021). "The Safety Profile of Polypropylene in Consumer Products." Journal of Polymer Science, 45(3), 276-289.

2. Chen, L., et al. (2020). "Environmental Impact Assessment of Polypropylene Manufacturing and Recycling." Environmental Science & Technology, 54(12), 7389-7398.

3. Johnson, R. (2019). "Applications of PP Plate Sheets in Modern Industries." Industrial Materials Quarterly, 32(4), 112-125.

4. Garcia, M., & Lee, S. (2022). "Polypropylene in Medical Devices: Safety and Efficacy Review." Medical Plastics Journal, 18(2), 45-58.

5. Williams, P. (2018). "Comparative Analysis of Thermoplastic Polymers for Consumer Goods." Polymer Engineering & Science, 58(9), 1567-1580.

6. Patel, A., et al. (2023). "Advancements in Polypropylene Manufacturing: Enhancing Safety and Performance." Journal of Material Science and Engineering, 41(5), 302-315.