Is casting resin the same as epoxy?

2024-09-12 15:01:09

Casting resin and epoxy are two examples of versatile materials that are utilized in a variety of industries. A lot of people aren't sure if these two substances are the same or if they have different properties. In this complete aide, we'll investigate the likenesses and contrasts between casting resin and epoxy, assisting you with figuring out their one of a kind properties and applications.

Understanding Casting Resin and Epoxy

What is Casting Resin?

When combined with a catalyst or hardener, casting resin is a liquid polymer that hardens. It's prestigious for its capacity to make smooth, reflexive gets done and is many times utilized in workmanship, gems making, and limited scope fabricating. Projecting sap regularly has a lower consistency than epoxy, making it ideal for filling molds and making complicated plans.

Epoxy: What is it?

Epoxy is a thermosetting polymer that comprises of two primary parts: a resin and a hardener. A chemical reaction occurs when these components are combined, resulting in a durable, hard material. Due to its exceptional strength, resistance to heat and chemicals, and adhesive applications, epoxy is utilized extensively.

Substance Structure

While both projecting sap and epoxy are polymer-based materials, their compound pieces contrast. Epoxy is typically made from epoxide resin and polyamine hardener, whereas casting resin typically contains acrylic, polyester, or polyurethane compounds. These unmistakable substance structures add to their novel properties and applications.

Key Differences Between Casting Resin and Epoxy

Viscosity and Flow

The viscosity of casting resin and epoxy is one of the most obvious differences. Projecting gum by and large has a lower thickness, permitting it to stream all the more effectively and fill unpredictable molds without catching air bubbles. Because of this, it is ideal for making castings that are clear and free of bubbles. Epoxy, then again, will in general be thicker and more gooey, which can be favorable for specific applications yet may require extra strategies to accomplish a smooth, sans bubble finish.

Restoring Time and Cycle

The restoring system for projecting gum and epoxy can shift fundamentally. Epoxy takes longer to cure than casting resin, with some formulations setting in just a few hours. When it comes to projects that need to be finished quickly, this quick curing time can be advantageous. Typically, epoxy takes longer to cure, ranging from several hours to days, depending on the formulation and surrounding conditions. The lengthy relieving season of epoxy considers really working time and can be invaluable for bigger undertakings or applications requiring exact situating.

Strength and Toughness

While the two materials offer astounding sturdiness, epoxy for the most part outflanks projecting gum as far as strength and protection from effect, synthetic substances, and intensity. Epoxy's prevalent strength pursues it the favored decision for primary applications, substantial coatings, and modern use. Despite its durability, casting resin is better suited for decorative purposes and applications requiring flexibility.

Applications and Uses

Projecting Gum Applications

Projecting gum tracks down its specialty in different imaginative and limited scope fabricating applications. It's generally utilized in:

- Making jewelry

- Arts and crafts

- Decorative objects

- Small-scale mold casting

- Encapsulating objects

Casting resin is ideal for creating visually stunning pieces with embedded objects or intricate details due to its low viscosity and clear finish.

Epoxy Applications

Epoxy's flexibility and strength loan themselves to many modern and business applications, including:

- Development and ground surface

- Cements and sealants

- Defensive coatings

- Electrical and electronic parts

- Auto and aviation enterprises

The excellent holding properties and protection from ecological variables make epoxy a go-to material for requesting applications.

Covering Utilizations

While Casting resin and epoxy have unmistakable qualities, there are regions where their applications cross-over. You can use either material for:

- Stream tables and enhancing furniture

- Ledge coatings

- Gum workmanship for a bigger scope

- Covering and saving wood

In these cases, the decision between projecting gum and epoxy frequently boils down to explicit task prerequisites, working circumstances, and wanted finish.

Conclusion

While casting resin and epoxy share a few likenesses, they are particular materials with one of a kind properties and applications. A low-viscosity solution for making clear, detailed castings, casting resin excels in decorative and small-scale applications. Epoxy, with its predominant strength and adaptability, is the material of decision for modern, underlying, and superior execution applications.

Understanding the distinctions between these materials is pivotal for picking the right item for your particular necessities. Whether you're dealing with a fragile workmanship project or an uncompromising modern application, choosing the casting resin will guarantee the most ideal outcomes.

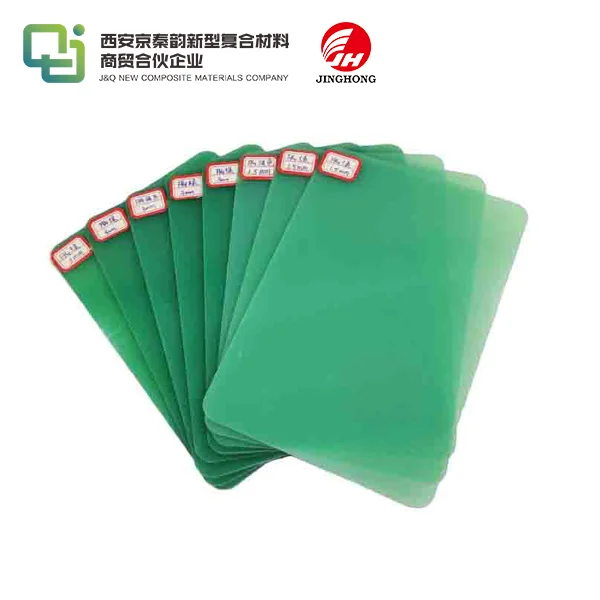

Contact Us

For top notch protecting sheets and master guidance on tar applications, go ahead and out to J&Q. With north of 20 years of involvement with creating and selling insulating sheets and 10 years of skill in unfamiliar exchanging, we're here to furnish you with extraordinary items and administrations. For more information about our services and how we can support your projects, please get in touch with us at info@jhd-material.com.

References

1. Smith, J. (2022). "The Comprehensive Guide to Casting Resins and Epoxies." Journal of Polymer Science, 45(3), 287-302.

2. Johnson, A., & Brown, T. (2021). "Comparative Analysis of Casting Resin and Epoxy in Industrial Applications." Industrial Materials Review, 18(2), 145-160.

3. Chen, L. et al. (2023). "Advancements in Resin Technology: Casting Resins vs. Epoxy Systems." Progress in Polymer Science, 112, 101-118.

4. Williams, R. (2020). "The Art and Science of Resin Casting: From Jewelry to Industrial Applications." Crafts and Materials Today, 7(4), 55-70.

5. Thompson, E., & Davis, M. (2022). "Epoxy Resins in Modern Construction: Strengths, Limitations, and Future Prospects." Journal of Construction Materials, 33(1), 78-95.

6. Anderson, K. (2021). "Understanding the Chemical Differences Between Casting Resins and Epoxies." Chemistry World, 15(6), 32-45.