Is Bakelite Board Environmentally Friendly?

2024-07-31 17:13:32

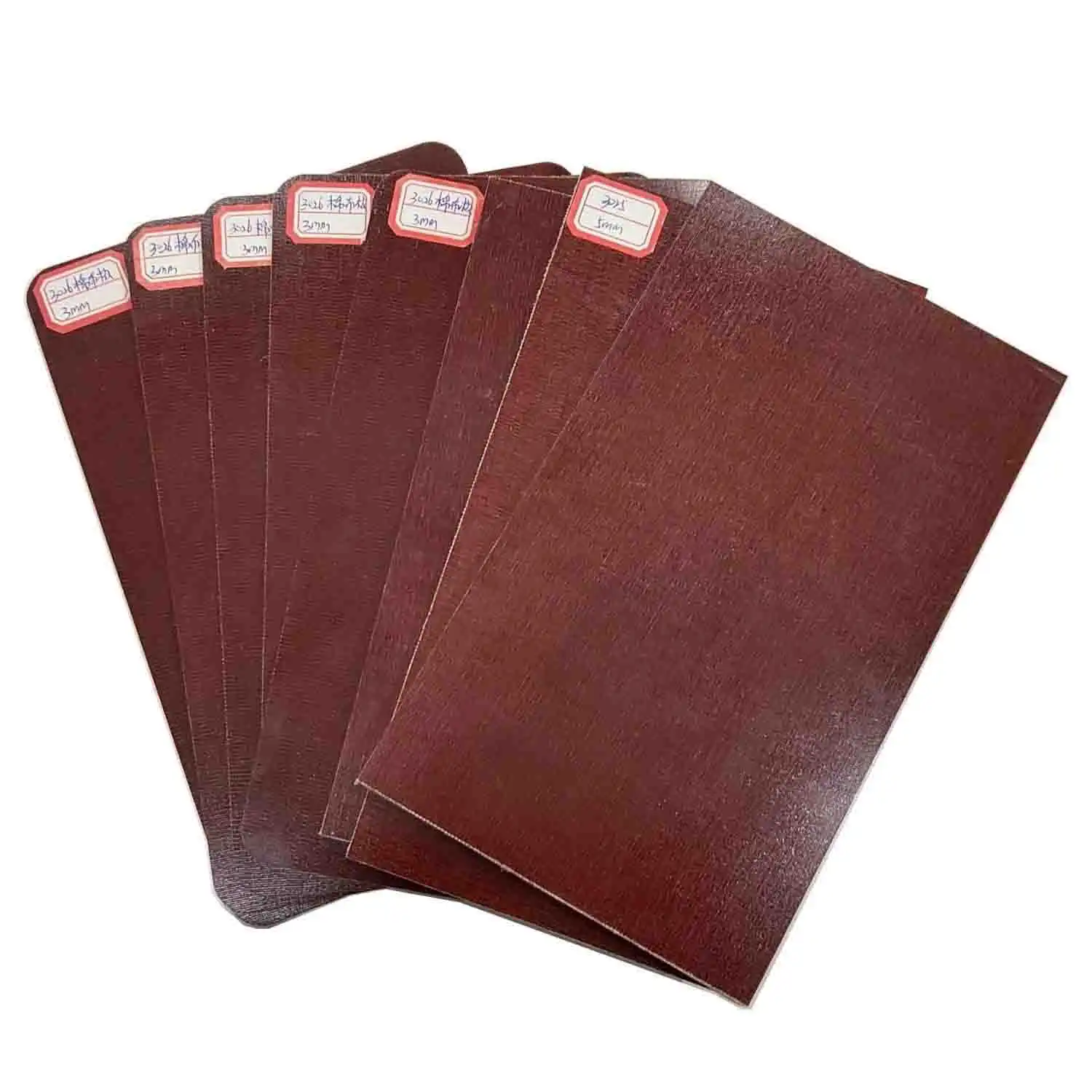

Bakelite board, a type of phenolic resin, has been widely used in various industries due to its excellent insulating properties, mechanical strength, and resistance to heat and chemicals. However, in an era increasingly focused on sustainability and environmental impact, it is crucial to evaluate the environmental friendliness of materials used in industrial applications. This blog explores whether Bakelite board is environmentally friendly by examining its production process, recyclability, and long-term environmental impact.

What Are the Environmental Impacts of Bakelite Board Production?

The environmental impact of any material begins with its production process. The production of Bakelite board involves several steps, each with its own environmental considerations.

Raw Materials and Sourcing

Bakelite is made by polymerizing phenol and formaldehyde, the two of which are gotten from oil.

The extraction and processing of petroleum has significant effects on the environment, including pollution, habitat disruption, and emissions of greenhouse gases. In addition, the production of formaldehyde and phenol requires energy and generates emissions of other pollutants and volatile organic compounds (VOCs).

Energy Consumption

The process of making Bakelite board uses a lot of energy. High temperatures and pressures are needed during the polymerization of phenol and formaldehyde to produce phenolic resin, which uses a lot of energy. Fossil fuels are frequently used as the energy source for these operations, which increases greenhouse gas emissions and contributes to climate change.

Chemical Emissions

Several potentially environmentally hazardous compounds are used in the Bakelite board manufacture process. Both formaldehyde and phenol are hazardous materials, and handling and manufacture of these compounds increases the possibility of leaks, accidents, and emissions. Although containment and proper management are required to reduce these dangers, the environmental impact remains.

Waste Generation

Waste materials are produced throughout the Bakelite board production process, including byproducts, defective goods, and offcuts. If these wastes are not appropriately managed, they may end up in landfills. Waste management procedures may become more difficult if hazardous materials are present, even though some waste can be recycled or used in other ways.

Can Bakelite Board Be Recycled or Repurposed?

Recycling and repurposing are critical aspects of assessing the environmental friendliness of a material. The ability to recycle or repurpose Bakelite board can significantly influence its overall environmental impact.

Challenges in Recycling

Because Bakelite board is a thermosetting plastic, it cannot be melted down and reformed like thermoplastics once it has dried and set. This feature makes recycling Bakelite using conventional methods difficult. In contrast to materials like polyethylene or aluminum, Bakelite cannot be recycled conventionally to create new items.

Potential for Repurposing

There are uses for Bakelite board notwithstanding the difficulty of recycling it in the conventional sense. Used Bakelite parts can be pulverized to a fine powder and used to fresh phenolic resin compositions as a filler. Although this method helps control trash and lessens the demand for virgin raw materials, it does not completely solve the problems associated with end-of-life disposal.

Chemical Recycling

Thermosetting plastics like Bakelite may be handled via sophisticated recycling techniques including chemical recycling. In chemical recycling, the polymer is broken down into its simplest chemical components so that new materials can be made. These technologies have little current impact on Bakelite recycling because they are still in the development stage and are not yet extensively used.

Incineration and Energy Recovery

Energy recovery combined with incineration is another way to handle garbage made with bakelite. By producing energy that may be used for other purposes, the incineration of Bakelite can lessen its total environmental impact. But since burning phenolic resins can release toxic compounds like furans and dioxins, this process needs to be carefully controlled.

Environmental Considerations

It is important to carefully analyze the environmental impact of either landfilling or incinerating Bakelite board. While cremation necessitates stringent controls to limit emissions, landfilling Bakelite can result in long-term environmental pollution. The development of efficient recycling and reuse techniques is essential to minimizing Bakelite board's environmental impact.

What Are the Long-Term Environmental Impacts of Bakelite Board?

Assessing the long-term environmental impacts of Bakelite board involves considering its durability, potential for pollution, and effects on ecosystems over time.

Durability and Longevity

One of the advantages of Bakelite board is its durability and long service life. Bakelite components can last for decades without significant degradation, reducing the need for frequent replacements. This durability can be seen as environmentally beneficial because it means fewer resources are needed to produce new components. However, it also means that once Bakelite products reach the end of their useful life, they persist in the environment for a long time if not properly managed.

Potential for Pollution

Bakelite board contains phenol and formaldehyde, both of which are hazardous substances. If Bakelite products are improperly disposed of or if they degrade over time in landfills, these chemicals can leach into the soil and groundwater, posing risks to environmental and human health. Ensuring proper disposal and containment is crucial to prevent such pollution.

Impact on Ecosystems

The long-term persistence of Bakelite board in the environment can have detrimental effects on ecosystems. As a non-biodegradable material, Bakelite can accumulate in landfills and potentially enter natural habitats if not properly managed. This accumulation can disrupt ecosystems and harm wildlife.

Carbon Footprint

The carbon footprint of Bakelite board includes emissions from its production, transportation, and disposal. The energy-intensive production process and the use of petroleum-based raw materials contribute significantly to its carbon footprint. Reducing energy consumption, improving recycling methods, and exploring alternative raw materials could help mitigate this impact.

Alternatives and Sustainability

Exploring alternative materials with lower environmental impacts is an important aspect of improving sustainability. Materials such as bioplastics, which are derived from renewable resources and designed to be more easily recyclable or biodegradable, offer potential alternatives to traditional phenolic resins like Bakelite. Continued research and development in this area are essential for reducing the environmental footprint of industrial materials.

Conclusion

Bakelite board, while offering significant advantages in terms of durability and performance, presents notable environmental challenges. The production process is energy-intensive and relies on petroleum-based raw materials, contributing to greenhouse gas emissions and pollution. Recycling and repurposing options are limited, and the long-term environmental impacts include potential pollution and ecosystem disruption. Addressing these challenges requires advancements in recycling technologies, effective waste management, and the development of sustainable alternatives.

References

1. "Environmental Impact of Phenolic Resins," Journal of Sustainable Materials.

2. "Recycling and Disposal of Thermosetting Plastics," Advanced Materials Recycling Review.

3. "The Role of Bakelite in Modern Industry," Engineering Materials Today.

4. "Chemical Resistance and Environmental Stability of Bakelite," Industrial Materials Journal.

5. "Sustainable Alternatives to Traditional Plastics," Journal of Green Engineering.