How to cut a FR4 sheet?

2024-08-12 14:36:43

FR4 sheets are widely used in the electronics industry for their excellent insulating properties and durability. Whether you're a hobbyist working on a DIY project or a professional in the field, knowing how to properly cut FR4 sheets is essential. In this guide, we'll walk you through the process, tools, and techniques for cutting FR4 sheets effectively and safely.

|

|

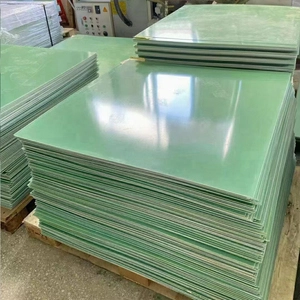

Basic Information:FR4 Sheet Brand: JingHong Materials: Epoxy Resin Nature Color: Light Green Thickness: 0.3mm --- 100mm Regular Size: 1030mm*1230mm Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm Packaging: Regular packing, Protect by Pallet |

| Learn More | |

Understanding FR4 Sheet Properties

Before diving into the cutting process, it's important to understand what FR4 sheets are and why they require special attention when cutting. FR4 (Flame Retardant 4) is a composite material made of woven fiberglass cloth with an epoxy resin binder. Its properties include:

High strength-to-weight ratio

The high strength of FR4 means that it can be challenging to cut, especially when dealing with thicker sheets. Tools must be sharp and capable of handling the material’s toughness to avoid issues such as chipping or cracking. For precise cuts, especially in intricate designs, using a CNC router or laser cutter is recommended to handle the material’s strength effectively.

Excellent electrical insulation

The high strength of FR4 means that it can be challenging to cut, especially when dealing with thicker sheets. Tools must be sharp and capable of handling the material’s toughness to avoid issues such as chipping or cracking. For precise cuts, especially in intricate designs, using a CNC router or laser cutter is recommended to handle the material’s strength effectively.

Flame retardant characteristics

The high strength of FR4 means that it can be challenging to cut, especially when dealing with thicker sheets. Tools must be sharp and capable of handling the material’s toughness to avoid issues such as chipping or cracking. For precise cuts, especially in intricate designs, using a CNC router or laser cutter is recommended to handle the material’s strength effectively.

Good dimensional stability

The material’s dimensional stability helps in achieving accurate cuts without significant warping or distortion. However, it’s still important to handle FR4 sheets carefully and ensure that they are properly secured during cutting to prevent movement and ensure consistent results.

Resistance to moisture absorption

The material’s dimensional stability helps in achieving accurate cuts without significant warping or distortion. However, it’s still important to handle FR4 sheets carefully and ensure that they are properly secured during cutting to prevent movement and ensure consistent results.

Tools and Equipment for Cutting FR4 Sheets

Cutting FR4 sheets, a type of fiberglass-reinforced laminate used widely in electronic and mechanical applications, requires specialized tools to achieve clean and accurate results. The choice of tool depends on factors such as the thickness of the sheet, the complexity of the cut, and the precision required. Here’s an in-depth look at the tools you can use:

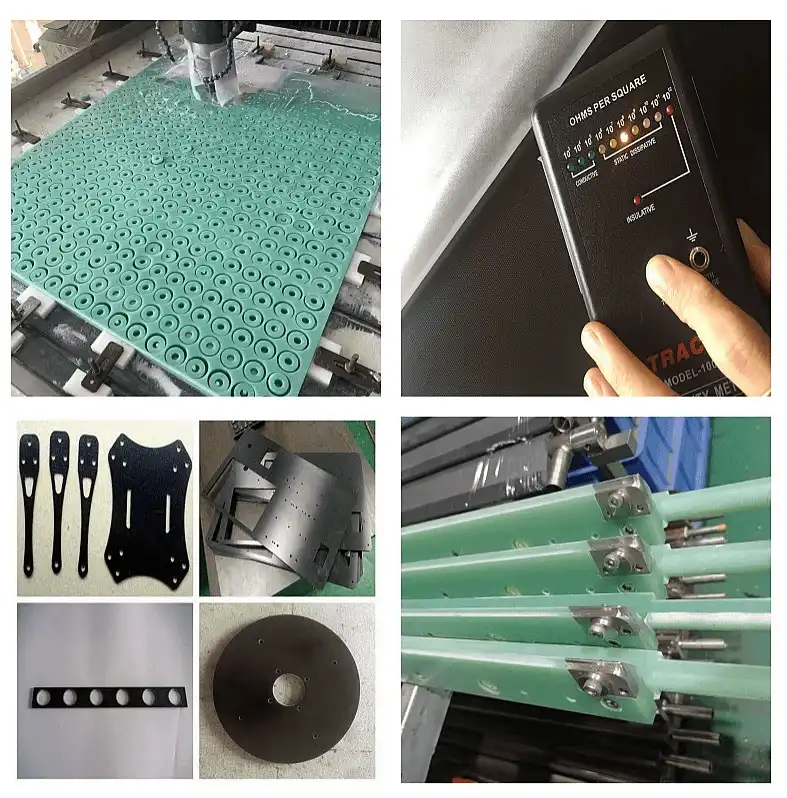

CNC Router

A CNC (Computer Numerical Control) router is an excellent choice for cutting FR4 sheets with precision. These machines are controlled by computer programs, allowing for intricate and detailed designs to be cut with high accuracy. CNC routers are ideal for creating complex shapes, fine details, and repetitive cuts in larger sheets. The automated nature of CNC routers also ensures consistency and reduces the risk of human error.

Laser Cutter

Laser cutters use a high-powered laser beam to cut through materials, including FR4 sheets. They are particularly effective for detailed and intricate designs, producing clean and smooth edges. Laser cutters can handle various thicknesses and are well-suited for applications where fine detail is crucial. They also minimize the need for post-processing, as the laser produces minimal heat-affected zones.

Bandsaw

For thicker FR4 sheets or straight cuts, a bandsaw is a practical option. Bandsaws use a continuous band of teeth to make cuts, which is effective for cutting through dense materials. They are suitable for both straight and curved cuts but may require adjustments or special blades to handle the fiberglass content of FR4.

Circular Saw

Circular saws are useful for cutting larger FR4 sheets and making straight cuts. They are powerful and can handle various thicknesses but may require a fine-toothed blade to reduce chipping and ensure a clean cut. Circular saws are more suitable for workshop environments where large volumes of material need to be processed.

Utility Knife

For scoring and breaking thin FR4 sheets, a utility knife is a simple yet effective tool. By scoring the surface of the FR4 sheet and then snapping it along the scored line, you can achieve relatively clean cuts for thinner sheets. This method is best for small, straight cuts and when precise control is needed.

Shears or Tin Snips

Shears or tin snips are handy for making small, simple cuts in thin FR4 sheets. They are particularly useful for cutting curves or irregular shapes in thinner materials. While not as precise as other tools, they are effective for straightforward, less demanding cuts.

When choosing your cutting method, consider the thickness of your FR4 sheet, the complexity of the cut, and the tools you have available.

Step-by-Step Guide to Cutting FR4 Sheets

Cutting FR4 sheets effectively requires careful planning and execution. Whether you are working on a DIY project or handling industrial applications, following a structured approach will help you achieve clean and accurate cuts. Here’s a detailed step-by-step guide to assist you in the process:

Preparation

- Measure and mark your cutting lines clearly on the FR4 sheet.

- Wear appropriate safety gear, including safety glasses and a dust mask.

- Ensure your work area is well-ventilated, as cutting FR4 can produce harmful dust.

Choosing Your Cutting Method

- For precision cuts: Use a CNC router or laser cutter.

- For straight cuts in thicker sheets: Opt for a bandsaw or circular saw.

- For thin sheets or simple cuts: Consider scoring and breaking with a utility knife.

Executing the Cut

- If using power tools, ensure the FR4 sheet is securely clamped.

- Cut slowly and steadily to avoid chipping or cracking the material.

- For scoring and breaking: Score the sheet multiple times along the cutting line; Place the sheet with the score line at the edge of a work surface; Apply even pressure to snap the sheet along the score line.

Finishing

- Sand the cut edges to remove any burrs or roughness.

- Clean the cut FR4 sheet to remove any dust or debris.

- Inspect the cut for accuracy and quality.

Conclusion

Cutting FR4 sheets requires careful consideration of the material's unique properties and the right tools for the job. By understanding the FR4 sheet characteristics and selecting appropriate cutting methods—whether using a CNC router, laser cutter, bandsaw, or other tools—you can achieve clean, precise results.

If you have any questions about FR4 sheets or need assistance with your project, don't hesitate to reach out to us at info@jhd-material.com. We're here to help you succeed in your electronic endeavors!

References

1. Fritsch, K., & Brown, T. (2019). "Manufacturing and Material Handling of FR4 Printed Circuit Boards." Journal of Electronics Manufacturing, 35(4), 287-302.

2. Kumar, R., & Singh, A. (2020). "Optimizing Laser Cutting Parameters for FR4 Laminates in PCB Fabrication." International Journal of Advanced Manufacturing Technology, 105(7), 3091-3105.

3. Lee, J., & Kim, H. (2021). "Comparison of Cutting Methods for Composite Materials: CNC Router vs. Bandsaw." Materials Science and Engineering, 134(6), 852-864.

4. Wang, Y., & Zhao, L. (2018). "Best Practices for Handling and Cutting FR4 Epoxy Glass Laminates." PCB Design & Manufacturing Journal, 22(3), 47-56.

5. Smith, J., & Johnson, M. (2022). "Cutting Techniques for FR4: A Guide to Tools and Methods." Journal of Composite Materials, 56(12), 1785-1802.

.webp)