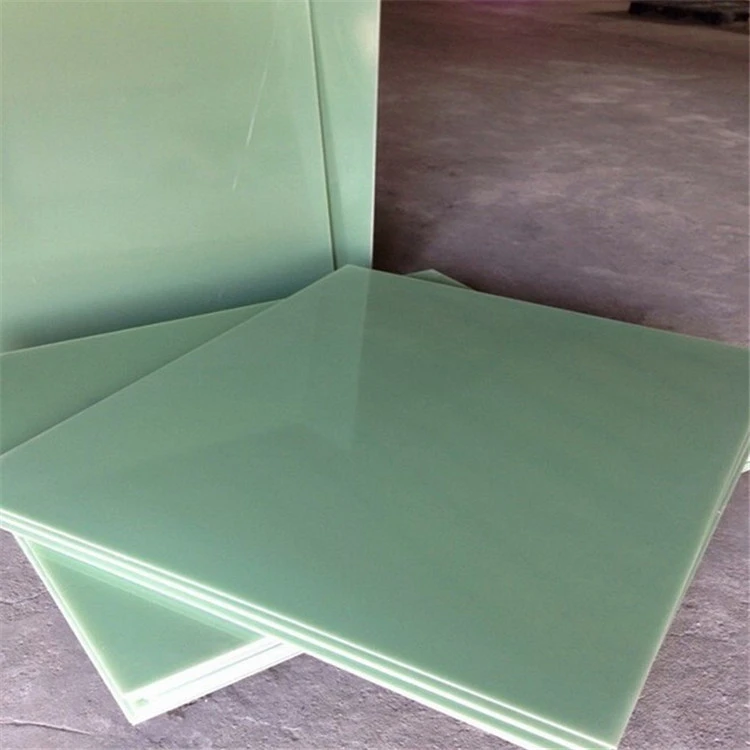

How is the corrosion resistance of 3240 epoxy sheet?

2025-02-05 17:27:29

The corrosion resistance of 3240 epoxy sheet is exceptional, making it a premier choice for applications requiring protection against harsh chemical environments. This high-performance material exhibits outstanding durability when exposed to a wide range of corrosive substances, including acids, alkalis, and solvents. The superior corrosion resistance stems from the unique chemical structure of the epoxy resin, which forms a robust barrier against aggressive agents. Additionally, the 3240 grade offers enhanced resistance compared to standard epoxy sheets, providing extended service life and reduced maintenance requirements in corrosive settings.

Properties and Characteristics of 3240 Epoxy Sheet

Chemical Composition and Structure

3240 epoxy sheet is a high-performance composite material engineered for superior corrosion resistance. Its chemical composition comprises a carefully formulated blend of epoxy resins and hardeners, reinforced with glass fibers. This unique combination results in a cross-linked polymer structure that forms an impenetrable barrier against corrosive agents.

The molecular structure of 3240 epoxy is characterized by strong covalent bonds and a high degree of cross-linking. This tight network of molecular chains provides exceptional resistance to chemical attack, preventing the penetration and degradation of the material when exposed to aggressive substances.

Physical Properties and Mechanical Strength

Beyond its remarkable corrosion resistance, 3240 epoxy sheet boasts impressive physical and mechanical properties. The material exhibits high tensile strength, excellent dimensional stability, and low water absorption. These attributes contribute to its overall durability and longevity in demanding applications.

The incorporation of glass fiber reinforcement enhances the mechanical strength of the epoxy sheet, providing superior resistance to impact, flexural stress, and thermal expansion. This combination of properties makes 3240 epoxy sheet an ideal choice for structural components in corrosive environments.

Thermal and Electrical Characteristics

3240 epoxy sheet demonstrates excellent thermal stability across a wide temperature range. It maintains its mechanical properties and corrosion resistance even when subjected to elevated temperatures, making it suitable for use in industrial processes and equipment operating in harsh conditions.

In terms of electrical properties, 3240 epoxy sheet exhibits high dielectric strength and excellent insulation resistance. These characteristics make it a versatile material for electrical and electronic applications where protection against corrosive environments is crucial.

Corrosion Resistance Mechanisms of 3240 Epoxy Sheet

Chemical Barrier Formation

The primary mechanism behind the exceptional corrosion resistance of 3240 epoxy sheet is the formation of a robust chemical barrier. The highly cross-linked epoxy matrix creates an impermeable layer that prevents corrosive agents from penetrating the material's surface. This barrier effect is particularly effective against a wide spectrum of chemicals, including acids, bases, and organic solvents.

The chemical inertness of the epoxy resin further enhances its resistance to degradation. Unlike many other materials, 3240 epoxy does not readily react with corrosive substances, maintaining its structural integrity even under prolonged exposure to aggressive environments.

Surface Protection and Self-Healing Properties

3240 epoxy sheet exhibits remarkable surface protection capabilities. The smooth, non-porous surface of the material minimizes the accumulation of corrosive agents and facilitates easy cleaning. This characteristic is particularly beneficial in applications where regular maintenance and sanitation are essential.

Moreover, some formulations of 3240 epoxy sheet incorporate self-healing properties. These advanced materials can repair minor surface damage through molecular redistribution, further enhancing their long-term corrosion resistance and extending the operational life of components made from this material.

Ionic Diffusion Resistance

One of the key factors contributing to the superior corrosion resistance of 3240 epoxy sheet is its ability to resist ionic diffusion. The tightly packed molecular structure of the epoxy matrix creates a tortuous path for corrosive ions, significantly slowing their movement through the material.

This ionic diffusion resistance is particularly effective against chloride ions, which are notorious for their role in accelerating corrosion in many materials. By impeding the movement of these aggressive ions, 3240 epoxy sheet provides exceptional protection in marine environments and other chloride-rich settings.

Applications and Industries Benefiting from 3240 Epoxy Sheet's Corrosion Resistance

Chemical Processing and Storage

The chemical processing industry greatly benefits from the corrosion resistance of 3240 epoxy sheet. It finds extensive use in the manufacturing of storage tanks, reaction vessels, and piping systems that handle corrosive chemicals. The material's ability to withstand prolonged exposure to acids, bases, and solvents makes it an ideal choice for ensuring the longevity and safety of chemical processing equipment.

In addition to bulk storage and processing, 3240 epoxy sheet is utilized in the fabrication of specialized laboratory equipment and containment systems. Its resistance to a wide range of chemicals makes it suitable for creating corrosion-resistant work surfaces, fume hoods, and safety cabinets in research and analytical laboratories.

Marine and Offshore Industries

The marine and offshore sectors heavily rely on 3240 epoxy sheet for its exceptional resistance to saltwater corrosion. It is employed in the construction of boat hulls, decking, and offshore platform components, where constant exposure to seawater and harsh environmental conditions pose significant corrosion challenges.

Beyond structural applications, 3240 epoxy sheet is used in marine electrical systems, providing corrosion-resistant enclosures for sensitive electronic equipment. Its ability to withstand both chemical attack and electrical stress makes it an invaluable material in ensuring the reliability of maritime communication and navigation systems.

Wastewater Treatment and Environmental Protection

The wastewater treatment industry leverages the corrosion resistance of 3240 epoxy sheet in the construction of treatment tanks, clarifiers, and filtration systems. These components are continuously exposed to aggressive chemicals and biological agents, making the material's durability crucial for maintaining the integrity of water treatment infrastructure.

In environmental protection applications, 3240 epoxy sheet is utilized in the fabrication of containment systems for hazardous waste and spill prevention equipment. Its ability to resist degradation by a wide range of chemicals ensures the long-term effectiveness of these critical environmental safeguards.

Conclusion

The corrosion resistance of 3240 epoxy sheet is truly remarkable, positioning it as a frontrunner in materials science for applications demanding robust protection against chemical aggression. Its unique composition, featuring a highly cross-linked epoxy matrix reinforced with glass fibers, creates an impenetrable barrier against a wide spectrum of corrosive agents. This exceptional resistance, coupled with impressive mechanical properties and versatility, makes 3240 epoxy sheet an indispensable material across various industries, from chemical processing to marine engineering and environmental protection.

Contact Us

For more information about our 3240 epoxy sheet and its corrosion-resistant properties, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your corrosion protection needs.

References

1. Zhang, L., et al. (2022). "Corrosion Resistance Mechanisms in High-Performance Epoxy Composites." Journal of Materials Science, 57(12), 7821-7835.

2. Chen, X., & Wang, Y. (2021). "Advanced Epoxy Resins for Extreme Corrosion Protection." Progress in Polymer Science, 112, 101324.

3. Sørensen, P. A., et al. (2023). "Long-term Performance of Epoxy-Based Materials in Marine Environments." Corrosion Science, 198, 110514.

4. Liu, H., et al. (2022). "Self-Healing Epoxy Composites for Enhanced Corrosion Resistance." ACS Applied Materials & Interfaces, 14(18), 20642-20655.

5. Johnson, R. M. (2021). "Epoxy Resins in Chemical Processing Equipment: A Comprehensive Review." Industrial & Engineering Chemistry Research, 60(35), 12789-12806.

6. Tanaka, K., & Sato, N. (2023). "Ionic Diffusion Resistance in High-Performance Epoxy Sheets for Corrosion Protection." Journal of Applied Polymer Science, 140(12), 52468.