FR4 Sheet Galaxy Wheel as a Polishing Tool for Milling has a lot of Milling Advantages

2022-08-22

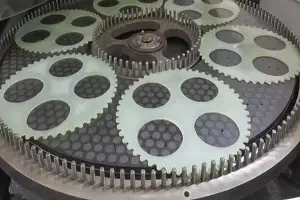

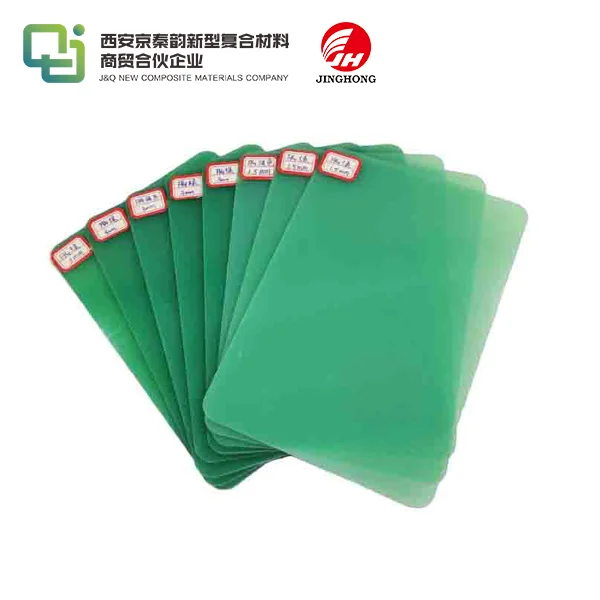

FR4 sheet Walking Wheel has a lot of advantages for milling for polishing. The materials of the stars include blue steel, stainless steel, and epoxy boards. The FR4 glass fiber plate is also an insulating board, which is also called "glass fiber board" and "epoxy resin board". The FR4 Fiber Plate Walking Wheel has the advantages of high temperature resistance (180 ~ 200 ° C), moisture resistance, good mechanical performance and dielectric performance. Common colors are white, yellow, black, and water green. FR4 Fiber Plate Walking Wheel is also called "polishing" and "polishing pads". It is a fixture for lens, silicon wafers, hard disks, glass and other plane polishing processes.

|

The characteristics of epoxy resin used by FR4 fiberglass sheet Star Wheel:

1. Then the intensity is good: epoxy resin and amine react, the structure produces a hydroxyl, and has good continuity for other materials.

2. Very good mechanical properties: epoxy resin itself has good internal agglomeration, and mechanical strength is better than ordinary resin.

3. Good processing performance: no volatile substances are generated during hardening, suitable for different processing conditions.

4. Low hardening contraction rate: 1 ~ 2%of the contraction rate, the smallest in thermosetry plastic.

5. High chemical stability: can tolerate the corrosion of multiple acids, pupa, salt and other materials.

6. Good electrical performance: volume resistance is about 1015ohm-cm or more.

7, good thermal resistance: solidification of heat resistance 100 ° C, special heat -resistant level resin can resist heat to above 200 ° C.

Brief description of the working principle of FR4 Insulation Fiberglass Sheet Star Wheel:

The method of using mechanical and chemical reactions to process the objects, making the original rough surface smooth. When our FR4 glass fiber board travels is running at a high speed, the surface of the product that needs to be polished will generate rolling and trace cutting force, so that the bump will slowly flatten, and it will become very smooth.

The development and change of FR4 Fiber Fiber Board Star Wheel production process:

1. The early FR4 glass fiber board gallery wheel was made of mold pressure method. Because there is no need for polishing workpieces, stamping production is selected.

However, the star wheel produced by this method has a rough texture and a high scrap rate.

2. With the continuous innovation of technology, the FR4 glass fiber board travel wheel can be processed with insulation parts processing center. The insulation processing center has high accuracy (within 0.02mm), smooth edges, no burrs, no machining traces, etc. Advantage. We only need to convert the drawings into the encoding into the computer to achieve automatic processing, high efficiency, accurate size, and non -deviation. Hassfull has MF1325 in the insulation parts processing center, with a table size of 1300 × 2500mm; vacuum tables, two -purpose suction clamping; servo disc knife library, sword change speed for 3 seconds; high -speed, high -light, high -precision processing can be achieved.