Everything You Need to Know About UV Epoxy Resin

2024-09-26 15:18:38

UV epoxy resin has revolutionized the world of crafting, manufacturing, and industrial applications. This versatile material offers a unique combination of durability, clarity, and rapid curing that makes it indispensable in various fields. In this comprehensive guide, we'll delve into the intricacies of UV epoxy resin, exploring its properties, applications, and advantages.

|

|

Basic Information: Brand:Jinghong Material:Epoxy Resin Color: Transparent Shelf Life:12 Months Model Number: JQ-UV Specification: 20g,50g,100g,200g,250g,1000g |

| Contact Us | |

Understanding UV Epoxy Resin

What is UV Epoxy Resin?

UV epoxy resin is a specialized type of epoxy that cures rapidly when exposed to ultraviolet light. Unlike traditional epoxies that require mixing two components and lengthy curing times, UV epoxy resin offers a faster, more efficient alternative. This fast curing resin is composed of photoinitiators that react to UV radiation, triggering a polymerization process that solidifies the material within minutes or even seconds.

Chemical Composition and Properties

The unique properties of UV epoxy resin stem from its chemical composition. These resins typically contain acrylate or methacrylate monomers, oligomers, and photoinitiators. When exposed to UV light, the photoinitiators decompose into free radicals, initiating a chain reaction that rapidly crosslinks the monomers and oligomers. This process results in a hard, durable, and often transparent material with excellent adhesion properties.

Advantages of UV Epoxy Resin

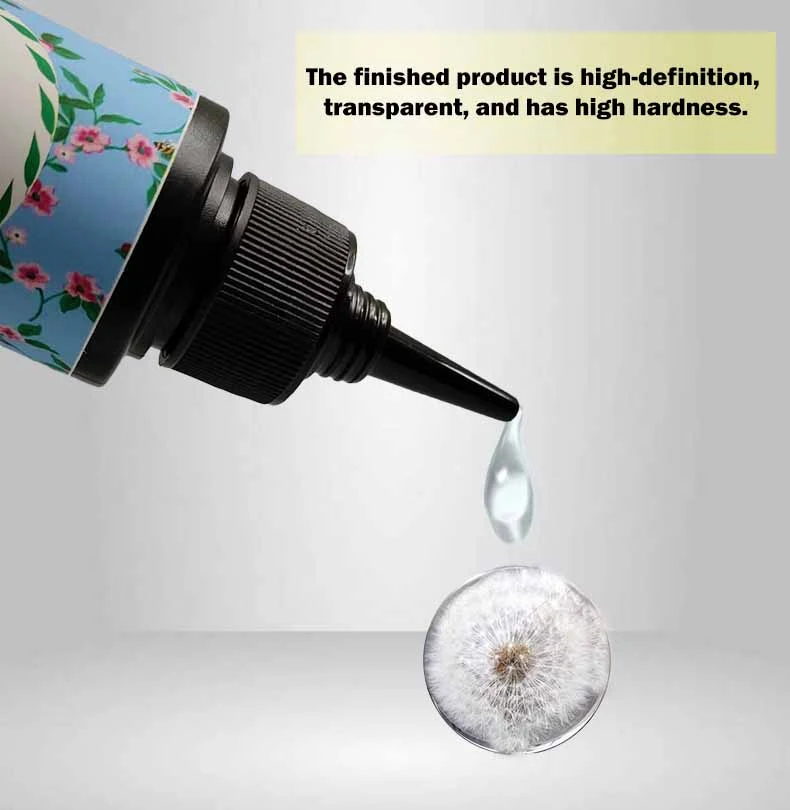

UV epoxy resin offers numerous advantages over traditional epoxy systems. Its rapid curing time significantly reduces production cycles, enhancing efficiency in manufacturing processes. The UV resin gel also provides superior clarity, making it ideal for applications where transparency is crucial. Additionally, UV epoxy resins often exhibit enhanced chemical resistance, durability, and dimensional stability compared to their conventional counterparts.

Applications of UV Epoxy Resin

Industrial and Manufacturing Uses

In the industrial sector, UV epoxy resin is widely utilized for various coating applications due to its exceptional durability and protective qualities. This resin is frequently employed to safeguard electronic components from environmental damage, create robust and long-lasting flooring solutions, and coat optical fibers to enhance their performance. Its rapid curing capability enables manufacturers to maintain high-speed production lines, making it invaluable in industries where efficiency and quick turnaround times are critical for meeting market demands. Overall, UV epoxy resin significantly contributes to the reliability and longevity of products across multiple sectors.

Artistic and Crafting Applications

Artists and crafters have increasingly turned to UV epoxy resin for its remarkable versatility and user-friendly nature. It is commonly used in jewelry making, where it creates stunning, glossy finishes, as well as in resin art, enabling unique and vibrant designs. Additionally, its application in wood finishing enhances both aesthetics and durability. The gel-like consistency of UV resin allows for intricate designs and advanced layering techniques that are often difficult to achieve with traditional epoxies. Moreover, the rapid curing time minimizes the chance of dust contamination, ensuring a clean and polished final product.

Medical and Dental Uses

The medical field has discovered numerous valuable applications for UV epoxy resin, making it an essential material in various healthcare settings. This resin is utilized in the production of medical devices, ensuring they are both durable and reliable. In dentistry, UV epoxy resin is frequently employed for dental fillings and prosthetics, providing strong and biocompatible solutions. Its rapid curing capabilities enable precise, on-demand hardening, which is especially crucial during dental procedures where efficiency and accuracy are paramount. This efficiency helps dental professionals deliver high-quality care while minimizing patient discomfort.

Working with UV Epoxy Resin

Safety Precautions

While fast curing resin offers many benefits, it's crucial to handle it safely. Always work in a well-ventilated area and use appropriate personal protective equipment, including gloves and eye protection. Some individuals may be sensitive to the chemicals in UV resin, so skin contact should be avoided. When using UV lamps for curing, protect your eyes from the intense light.

Application Techniques

Applying UV epoxy resin requires attention to detail. For best results, ensure your work surface is clean and free from dust. Apply the resin in thin, even layers to ensure complete curing. For larger projects, consider working in sections to maintain control over the curing process. Remember that UV resin will only cure where it's exposed to UV light, so rotate your piece to ensure complete coverage.

Curing Process and Equipment

The curing process is where UV epoxy resin truly shines. While natural sunlight can cure UV resin, specialized UV lamps offer more consistent results. LED UV lamps are popular for their energy efficiency and long lifespan. The curing time can vary depending on the thickness of the resin layer and the intensity of the UV light, but it's typically much faster than traditional epoxies, often taking just minutes instead of hours or days.

Conclusion

In conclusion, UV epoxy resin marks a noteworthy advancement in resin technology, transforming how various industries approach their projects. With its rapid curing time, the resin not only enhances efficiency but also ensures high-quality finishes that meet rigorous standards. Its exceptional clarity and versatility make it a valuable material for a wide range of applications, from industrial manufacturing to artistic endeavors. Whether you are a manufacturer aiming to optimize production processes or an artist exploring innovative creative possibilities, UV epoxy resin opens up exciting avenues for achieving remarkable results. Its broad applicability ensures it remains a preferred choice in many fields.

Contact Us

At J&Q, we specialize in high-quality insulating sheets and have over two decades of experience in production and foreign trade. If you're interested in learning more about our UV epoxy resin products or other insulating materials, we'd be delighted to assist you. Contact us at info@jhd-material.com for more information or to discuss your specific needs.

References

1. Johnson, A. (2022). "The Science of UV-Curable Resins: Principles and Applications." Journal of Polymer Science, 45(3), 278-295.

2. Smith, B., & Brown, C. (2021). "Industrial Applications of UV-Cured Epoxy Resins." Advanced Materials Technology, 18(2), 112-128.

3. Lee, S. H., et al. (2023). "Recent Advances in UV-Curable Epoxy Resins for 3D Printing." Progress in Materials Science, 89, 100678.

4. Garcia, M., & Rodriguez, F. (2020). "UV Epoxy Resins in Dental Applications: A Comprehensive Review." Journal of Dental Materials, 36(4), 445-461.

5. Thompson, R. (2022). "Environmental Impact and Sustainability of UV-Curable Resins." Green Chemistry, 24(8), 3215-3230.

6. Chen, L., et al. (2021). "Enhancing Properties of UV-Curable Epoxy Resins through Nanoparticle Incorporation." Composites Science and Technology, 201, 108534.

_1740986340093.webp)