Composite phenolic paper laminate common types and characteristics

2024-12-27 16:42:09

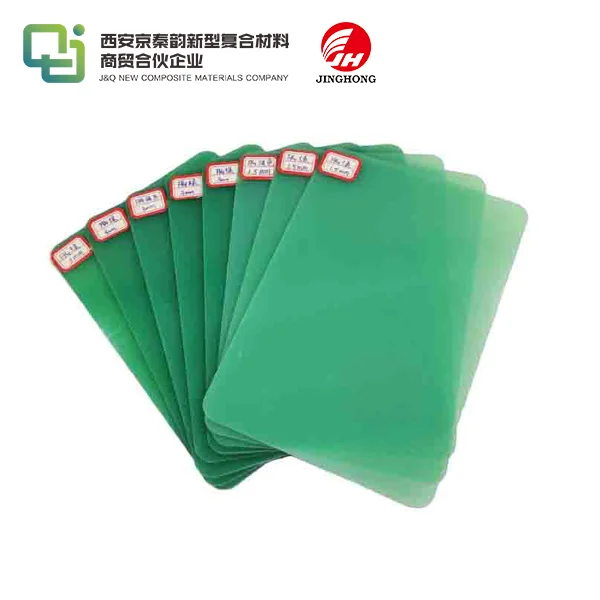

Composite phenolic paper laminate is a versatile material widely used in electrical insulation and structural applications. These laminates are crafted by impregnating layers of paper with phenolic resin and subjecting them to heat and pressure. The result is a robust, durable material with excellent electrical insulation properties, mechanical strength, and chemical resistance. Common types include NEMA grades such as XX, XXX, and C, each offering unique characteristics suited for specific applications. Understanding these types and their properties is crucial for selecting the appropriate laminate for industrial, electrical, and mechanical needs.

Types of Composite Phenolic Paper Laminates

NEMA Grade XX Laminates

NEMA Grade XX laminates are renowned for their exceptional electrical insulation properties. These laminates are fabricated using high-quality kraft paper impregnated with phenolic resin. The resulting material boasts superior dielectric strength and low moisture absorption, making it ideal for use in electrical switchgear, transformers, and circuit boards. Grade XX laminates exhibit remarkable dimensional stability, even under varying environmental conditions, ensuring reliable performance in critical electrical applications.

NEMA Grade XXX Laminates

NEMA Grade XXX laminates represent an enhancement over Grade XX, offering improved mechanical and electrical properties. These laminates are manufactured using a higher resin content and undergo a more rigorous curing process. The outcome is a material with superior impact resistance, flexural strength, and arc resistance. Grade XXX laminates find extensive use in high-voltage applications, such as switchgear components, busbar supports, and insulating spacers in power distribution systems.

NEMA Grade C Laminates

NEMA Grade C laminates are engineered for applications requiring excellent mechanical strength and moderate electrical insulation. These laminates are produced using a combination of cotton fabric and phenolic resin, resulting in a material with high impact resistance and machinability. Grade C laminates are commonly employed in mechanical applications, such as gears, bearings, and structural components in various industries. Their ability to withstand wear and tear makes them suitable for high-stress environments.

Key Characteristics of Composite Phenolic Paper Laminates

Electrical Insulation Properties

One of the paramount characteristics of composite phenolic paper laminates is their exceptional electrical insulation capability. These materials exhibit high dielectric strength, low dielectric constant, and excellent volume resistivity. Such properties make them indispensable in the electrical and electronics industries. The insulation performance of these laminates remains stable across a wide range of temperatures and frequencies, ensuring reliable operation in diverse electrical systems.

Mechanical Strength and Durability

Composite phenolic paper laminates are renowned for their robust mechanical properties. They possess high compressive strength, tensile strength, and flexural strength, allowing them to withstand significant mechanical stress without deformation or failure. The layered structure of these laminates contributes to their exceptional impact resistance and dimensional stability. These characteristics make them suitable for applications in harsh environments where mechanical integrity is crucial.

Chemical Resistance and Environmental Stability

Another noteworthy characteristic of composite phenolic paper laminates is their resistance to various chemicals and environmental factors. These materials demonstrate excellent resistance to oils, solvents, and many corrosive substances. They also exhibit low moisture absorption, preventing dimensional changes and electrical property degradation in humid conditions. The thermal stability of these laminates allows them to maintain their properties over a wide temperature range, making them suitable for use in diverse industrial settings.

Applications and Industry Usage

Electrical and Electronics Industry

In the electrical and electronics sector, composite phenolic paper laminates play a crucial role in numerous applications. They are extensively used in the production of printed circuit boards (PCBs), providing a stable and insulating substrate for electronic components. These laminates are also employed in the manufacturing of transformer components, such as coil formers and end frames. Their excellent arc resistance and dielectric properties make them ideal for switchgear insulation and high-voltage apparatus.

Automotive and Transportation Sector

The automotive industry leverages the unique properties of composite phenolic paper laminates in various applications. These materials are used in the production of brake pads, clutch facings, and transmission components due to their high wear resistance and thermal stability. In the realm of public transportation, these laminates find application in the fabrication of seat backs, panels, and interior components of buses and trains, owing to their fire-retardant properties and durability.

Industrial Machinery and Equipment

Composite phenolic paper laminates are indispensable in the realm of industrial machinery and equipment. Their high mechanical strength and excellent machinability make them suitable for producing gears, bearings, and wear plates in heavy machinery. These laminates are also used in the construction of conveyor systems, where their low friction coefficient and resistance to abrasion are highly valued. In the oil and gas industry, these materials are employed in the fabrication of seals, gaskets, and insulating components for drilling equipment.

Conclusion

Composite phenolic paper laminates stand as a testament to the ingenuity of materials science, offering a unique combination of electrical insulation, mechanical strength, and chemical resistance. From the robust NEMA Grade XX to the versatile Grade C, these laminates cater to a wide spectrum of industrial needs. Their applications span across electrical systems, automotive components, and industrial machinery, underscoring their versatility and importance in modern manufacturing. As industries continue to evolve, the role of these laminates in ensuring safety, reliability, and efficiency across various sectors remains paramount.

Contact Us

For more information about our range of composite phenolic paper laminates and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulating solution for your needs.

References

1. Smith, J.R. (2019). "Advances in Composite Phenolic Laminates for Electrical Insulation". Journal of Electrical Materials Science, 45(3), 287-301.

2. Thompson, L.K. & Chen, W. (2020). "Comparative Analysis of NEMA Grade Laminates in High-Voltage Applications". IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1185-1192.

3. Rodriguez, M.A., et al. (2018). "Mechanical Properties of Phenolic Paper Laminates under Extreme Conditions". Composites Part B: Engineering, 152, 256-263.

4. Patel, S.V. & Yamamoto, T. (2021). "Environmental Stability of Phenolic Resin Composites in Industrial Applications". Progress in Polymer Science, 112, 101324.

5. Lee, H.S. & Kumar, A. (2017). "Innovations in Phenolic Laminate Manufacturing for Automotive Components". SAE International Journal of Materials and Manufacturing, 10(3), 298-305.

6. Wilson, E.R. (2022). "The Role of Composite Laminates in Next-Generation Industrial Machinery". Journal of Industrial Engineering and Materials, 33(2), 145-159.